Novel potato powder making equipment

A technology of potato flour and equipment, which is applied in the direction of grain processing, etc., can solve the problems of easy waste of productivity, time and effort, and quality cannot be guaranteed, and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

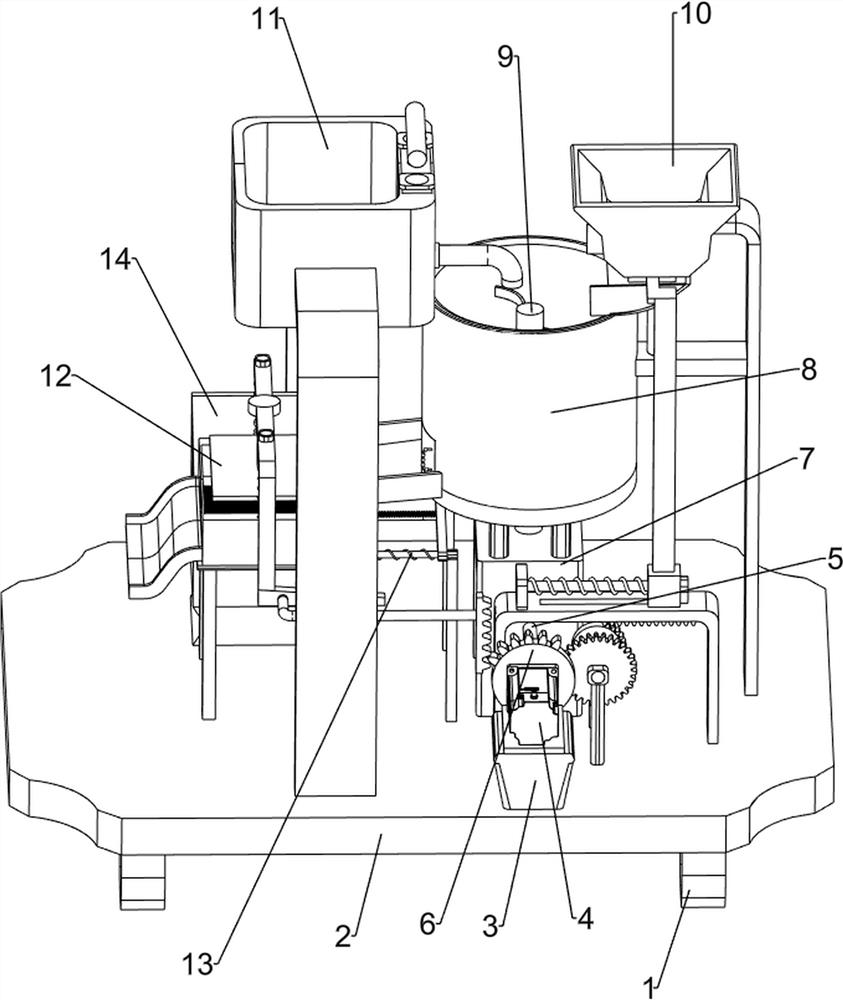

[0026] A new type of potato flour production equipment, such as figure 1 As shown, it includes a support block 1, a bottom plate 2, a base 3, a motor 4, a first rotating shaft 5, a first missing gear 6, a bracket 7, a stirring bucket 8 and a stirring knife 9, and a bottom plate is provided between the four support blocks 1 2. A base 3 is provided on the right front side of the bottom plate 2, a motor 4 is installed on the top of the base 3, a first rotating shaft 5 is connected to the output shaft of the motor 4, and a first missing gear 6 is arranged on the first rotating shaft 5. The rear part is provided with a bracket 7, the top of the bracket 7 is installed with a stirring barrel 8, and a stirring blade 9 is rotatably arranged in the stirring barrel 8, and the lower part of the stirring blade 9 is connected with the first rotating shaft 5 through a bevel gear set.

[0027] When people need to make potatoes into potato flour, this new type of potato flour production equipm...

Embodiment 2

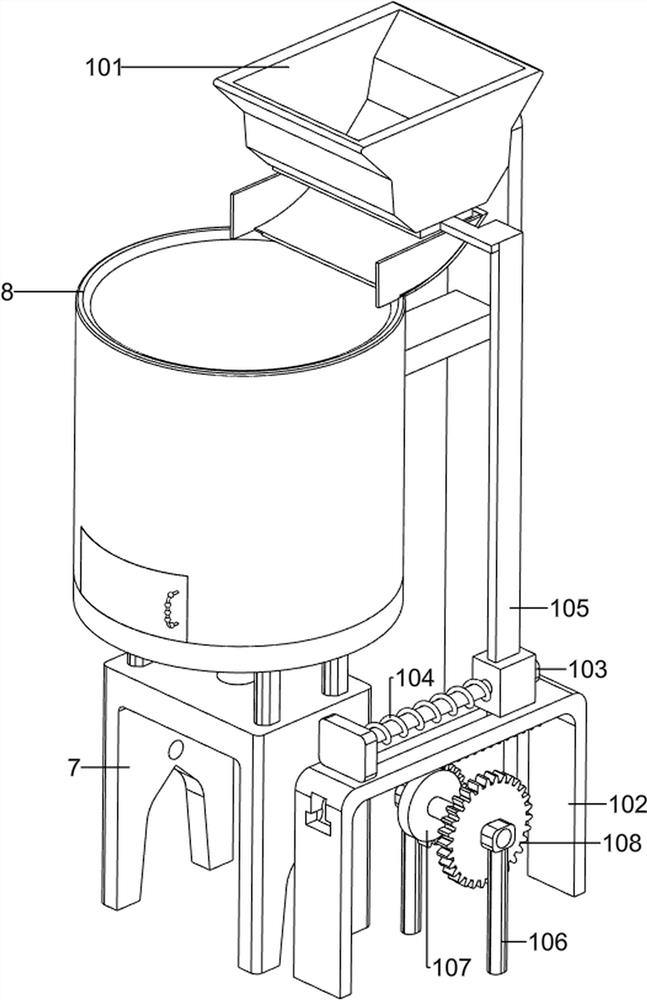

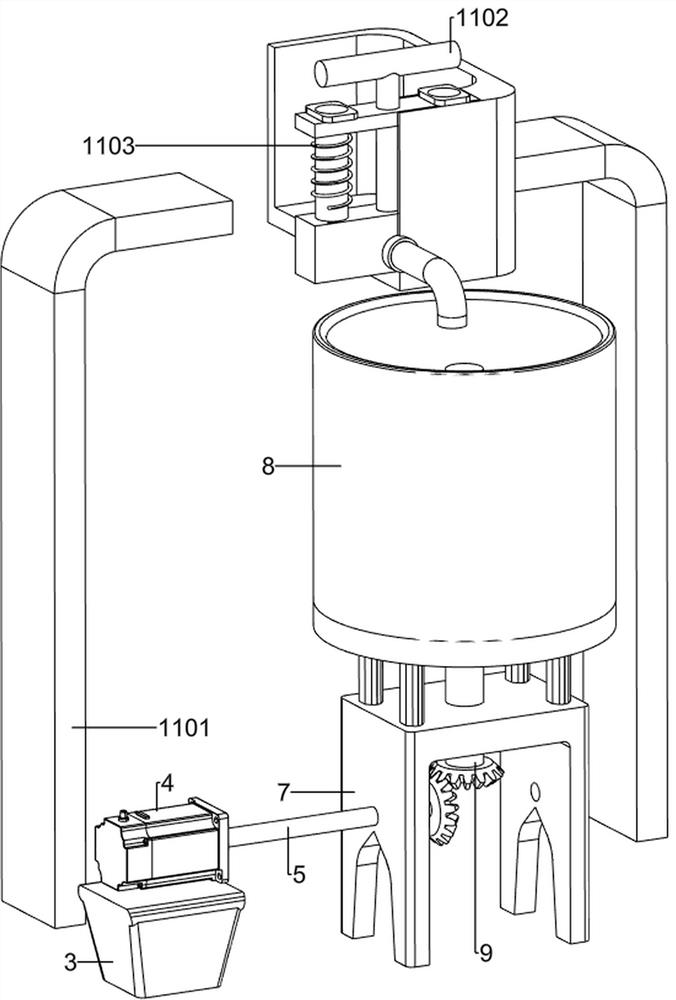

[0029] On the basis of Example 1, as Figure 2-5 As shown, it also includes an indirect blanking mechanism 10. The indirect blanking mechanism 10 includes a blanking frame 101, a first support plate 102, a first slide bar 103, a first spring 104, a baffle plate 105, and a first support column. 106. The second gear 107 and the first gear 108 are missing, a blanking frame 101 is provided in the middle of the right side of the bottom plate 2, a first support plate 102 is provided on the right front of the bottom plate 2, and the top of the first support plate 102 is slidably provided with a first support plate 102. Slide bar 103, a baffle plate 105 is connected to the right side of the first slide bar 103, the baffle plate 105 is slidably connected to the blanking frame 101, and a first spring is connected between the first slide bar 103 and the lower part of the baffle plate 105 104. The first spring 104 is wound around the first sliding rod 103. The right front part of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com