Device and construction method for dredging pipe blocked by final setting cement paste for sounding pipe cast-in-place pile

A cast-in-place pile and cement slurry technology, applied in chemical instruments and methods, cleaning methods and utensils, infrastructure engineering, etc., can solve the problem that the cement slurry cannot be replaced in time, so as to improve the dredging efficiency and convenience, improve the stability, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

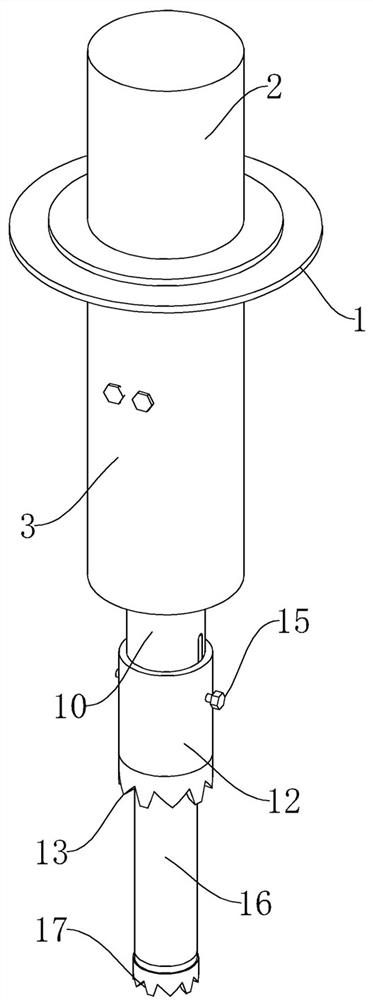

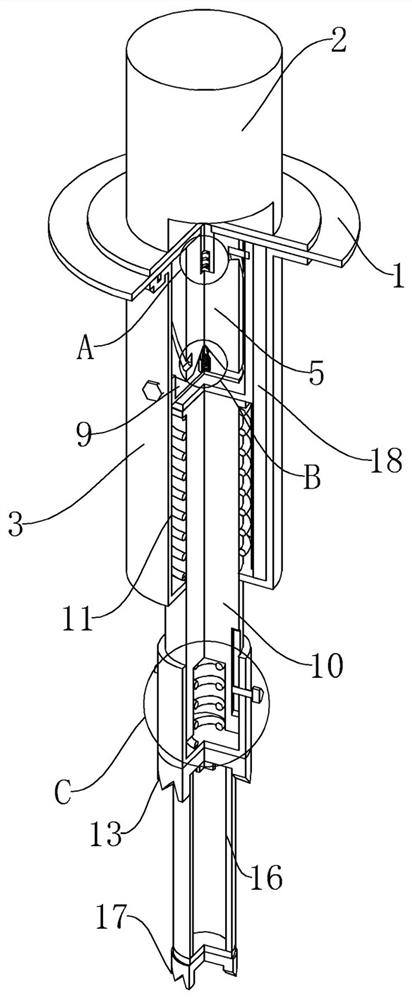

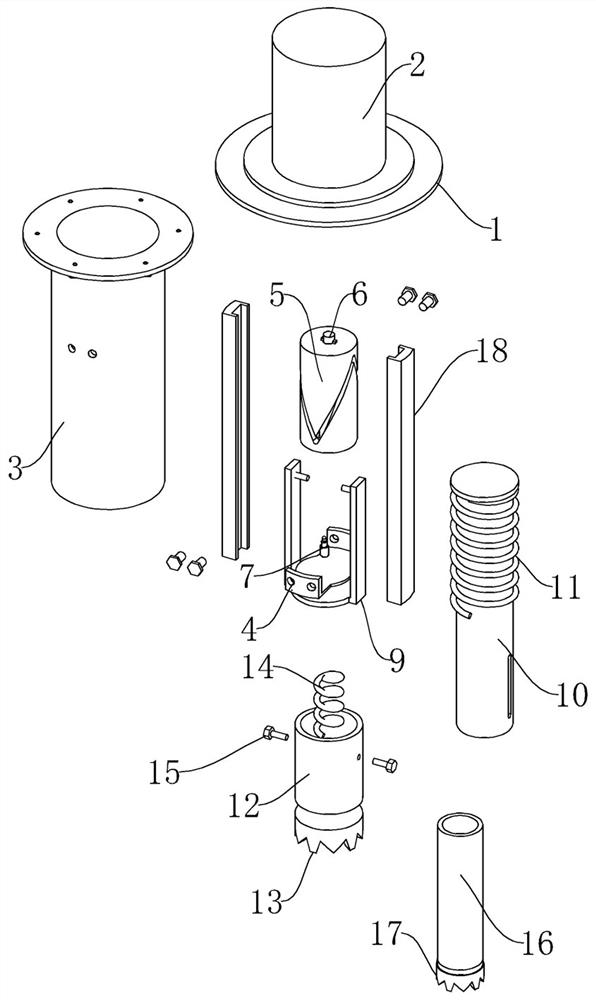

[0035] refer to Figure 1-8 A kind of device for dredging final set cement slurry plugging pipe by acoustic measuring tube pouring pile, comprising: fixed plate 1, the outer wall top of fixed plate 1 is installed with working motor 2; fixed frame 3 is fixedly arranged on the bottom of fixed plate 1, The inner wall of the frame 3 is fixedly provided with two sliding frames 18; the rotating assembly is fixedly arranged in the fixed frame 3 and movably arranged at the bottom of the fixed plate 1, and is used to convert the rotation into a telescopic push; and: the rotating assembly includes a fixed chassis 4, The rotating cylinder 5, the connecting slide bar 6 and the buffer assembly 7, the fixed base frame 4 is fixed in the fixed frame 3, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com