Multifunctional protection device for electric welding machine, and method thereof

A multifunctional electric welding machine and protective device technology, applied in welding protection devices, welding accessories, etc., can solve the problems of electric welding machine exposure to the sun, rain, electric leakage of electric welding machine, long-term use of electric leakage protection, etc. Adaptability, simple structure and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

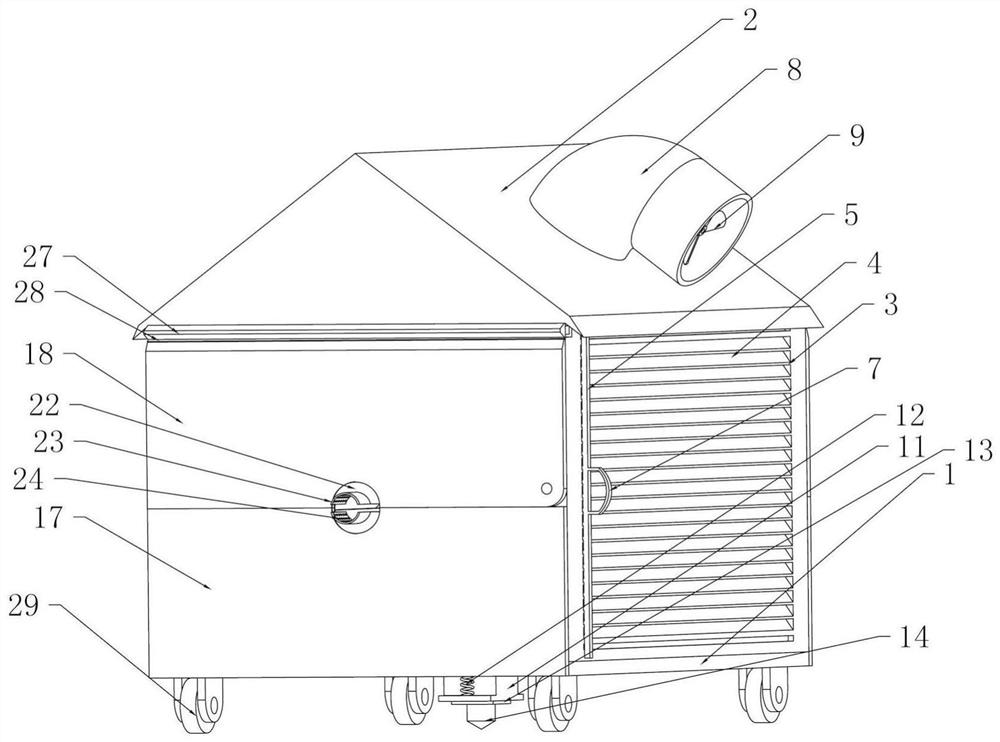

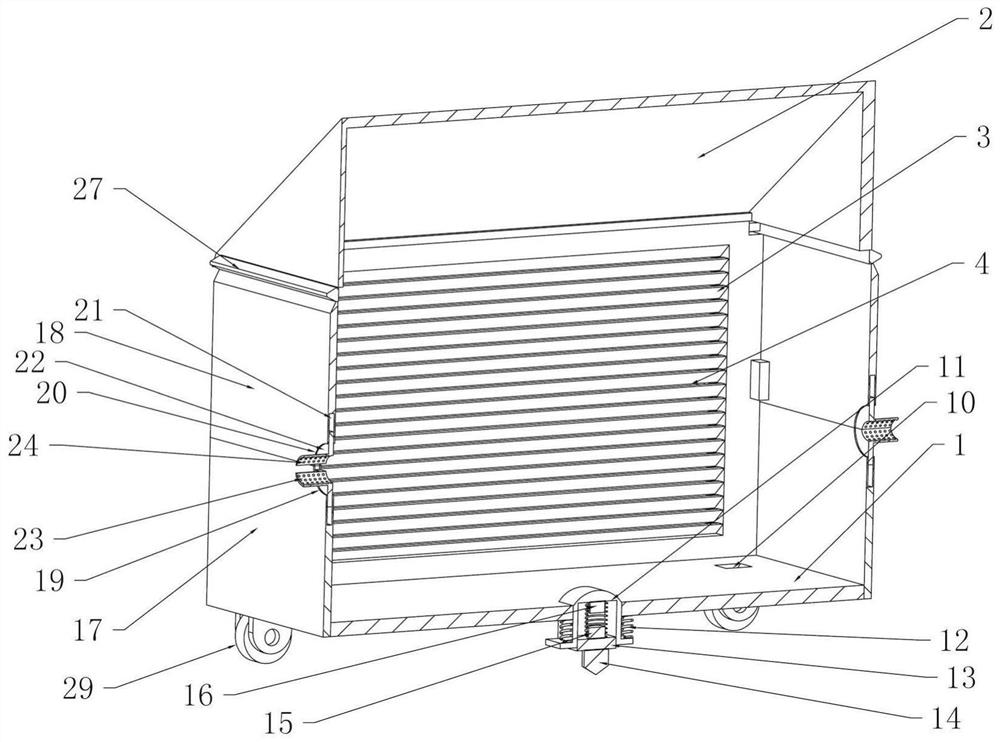

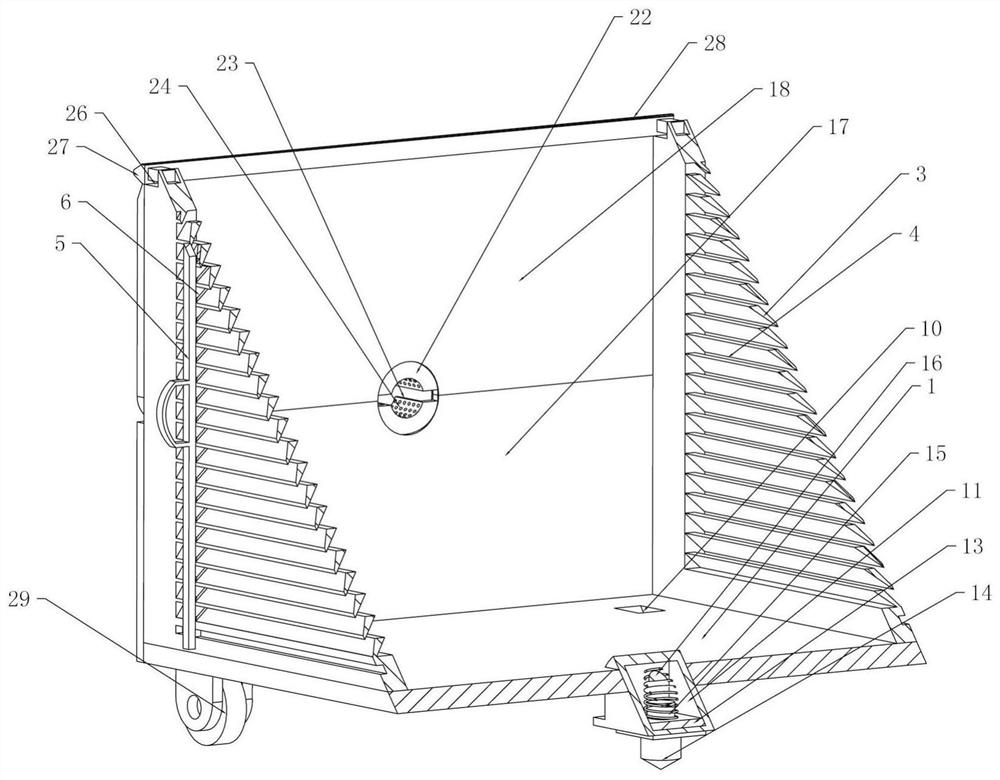

[0034] Embodiment 1, the present invention is a multifunctional electric welding machine protection device, including a box body 1, the electric welding machine is placed inside the box body 1, and the box body 1 provides a fixed support base for the rear structure , it is characterized in that the upper end of the box body 1 is fixedly connected with a top cover 2, and the electric welding machine is protected through the top cover 2 to prevent the collision of falling objects from high altitudes, sun exposure and rain, and the above described The upper end of the top cover 2 has a ridge, which is convenient for rainwater to fall in time, and avoids the accumulation of water at the upper end of the top cover 2, which infiltrates into the inside of the box body 1, and the left and right side walls of the box body 1 are fixedly connected with ventilation windows 3. Inside the ventilation window 3, there are several ventilation passages 4 inclined from top to bottom. Through the ...

Embodiment 2

[0040]Embodiment 2, on the basis of Embodiment 1, when the electric welding machine is running, it will generate a huge voltage, so when the electric welding machine leaks, it will cause harm to the human body, so this embodiment provides a leakage current To protect the structure, ground the electric welding machine and the box body 1 in time to avoid electric leakage causing harm to the staff. Specifically, the middle position of the lower end surface of the box body 1 slides up and down and is connected with a lifting sliding sleeve 11. The lifting sliding sleeve 11 slides up and down in the box 1, the lifting sliding sleeve 11 is fixedly connected with the limit spring 12, and the other end of the limiting spring 12 is fixedly connected with the lower end surface of the box 1 , the position of the lifting sliding sleeve 11 is limited by the limit spring 12, so that the initial position of the lifting sliding sleeve 11 is at the uppermost position, when the welding machine i...

Embodiment 3

[0042] Embodiment 3, on the basis of Embodiment 2, when the electric welding machine is pushed into the box body 1, the lifting sliding sleeve 11 will interfere and block the electric welding machine, so this embodiment provides A structure that enables the lifting sliding sleeve 11 to slide down smoothly. Specifically, the upper end surface of the lifting sliding sleeve 11 is arc-shaped, which is convenient for pressing the lifting sliding sleeve 11 during the sliding process of the electric welding machine. Moving, the lower end of the discharge column 14 is conical, and the discharge column 14 is inserted into the ground during the downward movement of the discharge column 14, so that the discharge column 14 is better grounded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com