Universal long screw shaft diameter machining supporting device

A support device and long screw technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of non-durability, poor versatility, inconvenient assembly and disassembly, etc., to overcome faster wear, simple structure, universal Good effect of sex and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

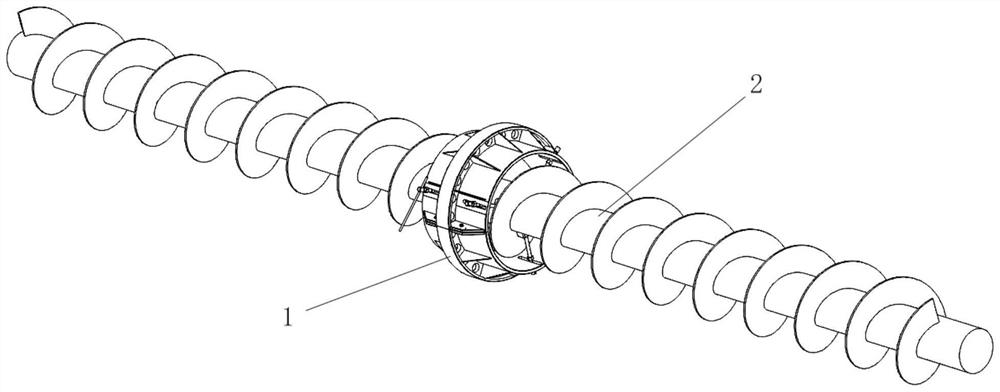

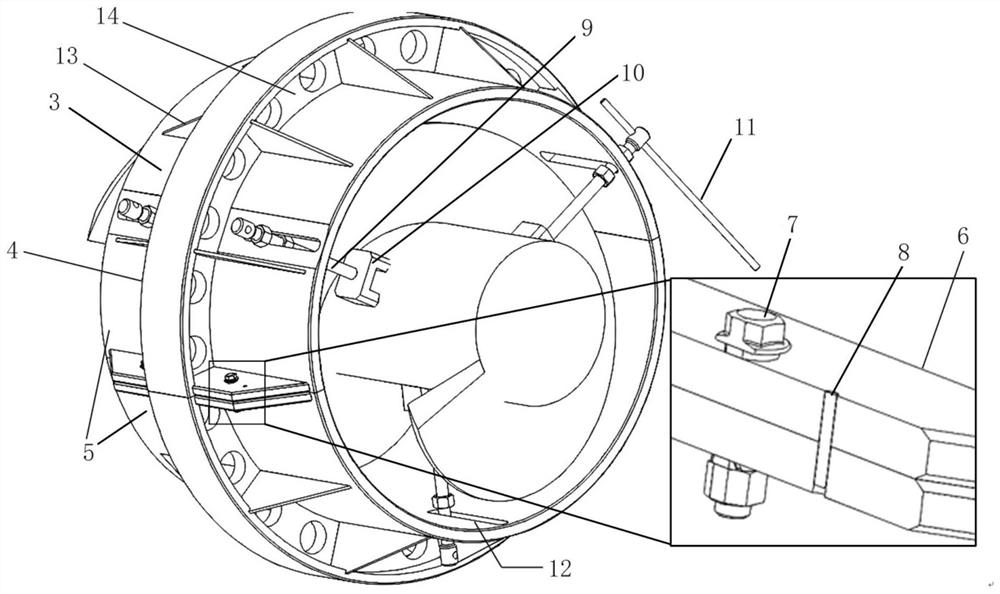

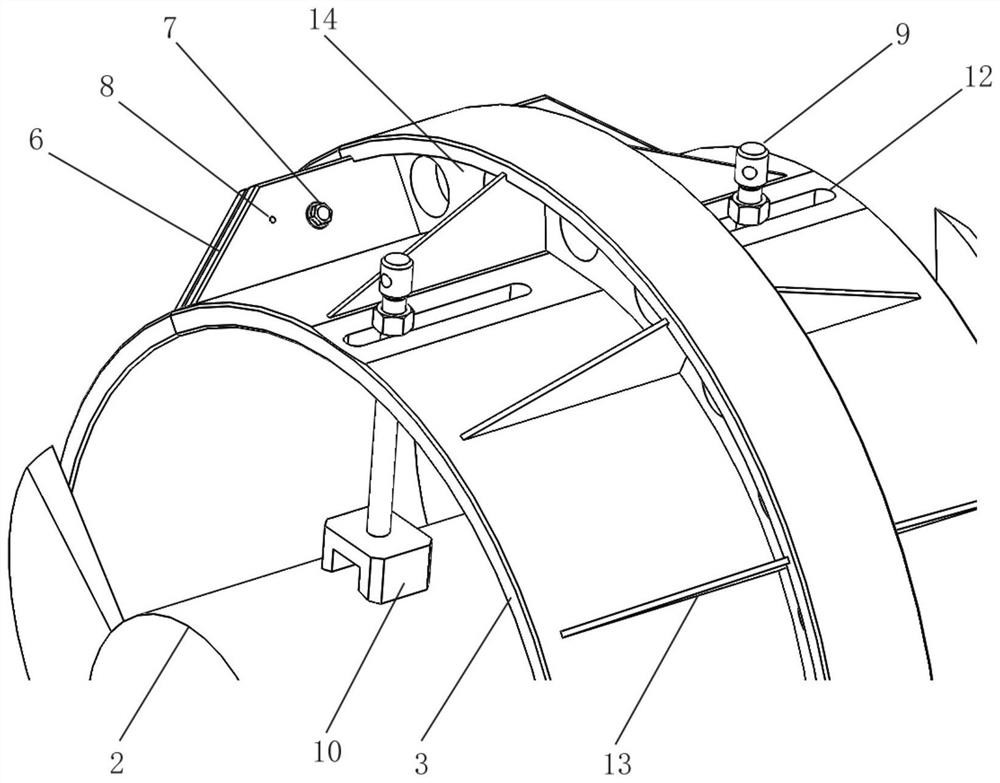

[0026] like Figure 1-3 As shown, a general-purpose long screw shaft diameter processing support device includes a support assembly 1 sleeved outside the long screw 2 to be processed, the support assembly 1 is supported by the center frame of the lathe, and the support assembly 1 is fixed on the Fixing mechanism on long screw 2. The fixing mechanism includes non-standard screws 9 and V-shaped blocks 10 (the fixing mechanism in this embodiment is the same as that in the Chinese invention patent CN2019103250336, so it will not be repeated here). The support assembly 1 includes a sleeve 3 and a support ring 14 , the support ring 14 is located in the middle of the outer wall of the sleeve 3 , and several slide grooves 12 are arranged on the sleeve 3 along the axial direction of the long screw 2 . The chute 12 is symmetrically distributed on both sides of the support ring 14 , wherein the spacing between adjacent chute 12 on the same side of the support ring 14 is equal, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com