Computer equipment production mold convenient to cool and plasticize

A technology for computer equipment and molds, which is applied in the field of computer equipment production molds that facilitate cooling and plasticity, can solve problems such as uneven internal density, and achieve the effects of improving service life, uniform mass density, and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

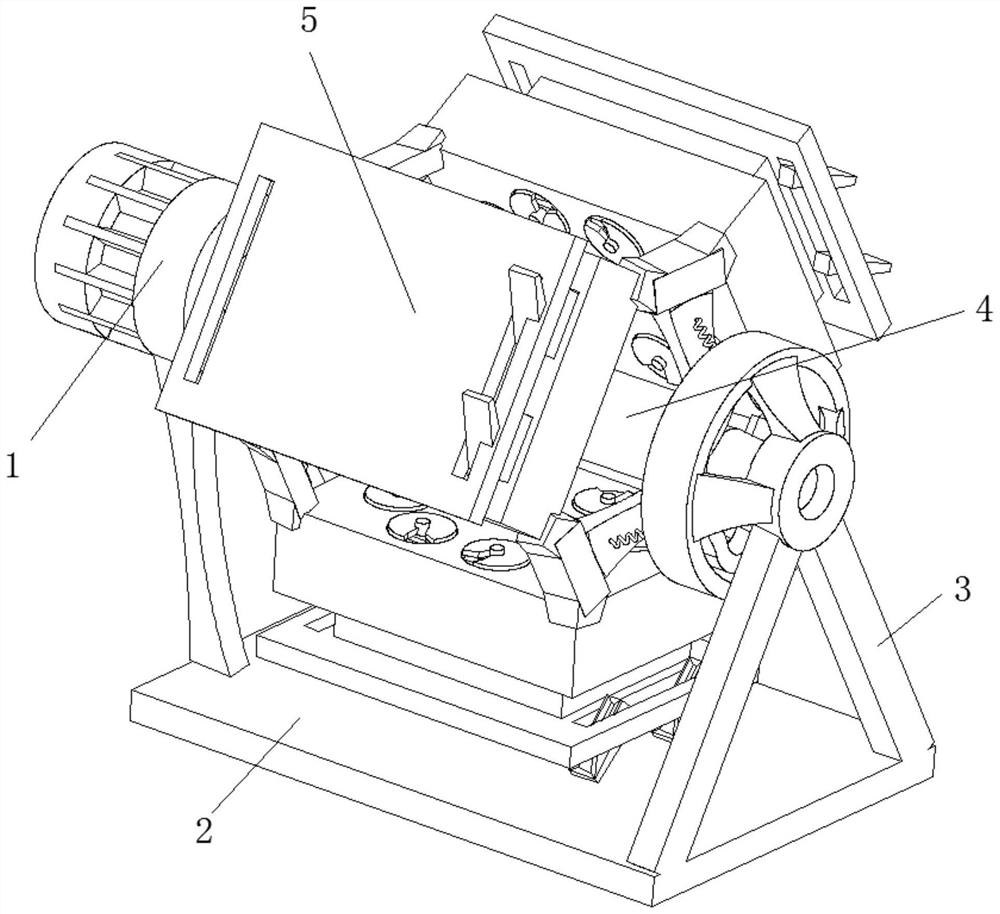

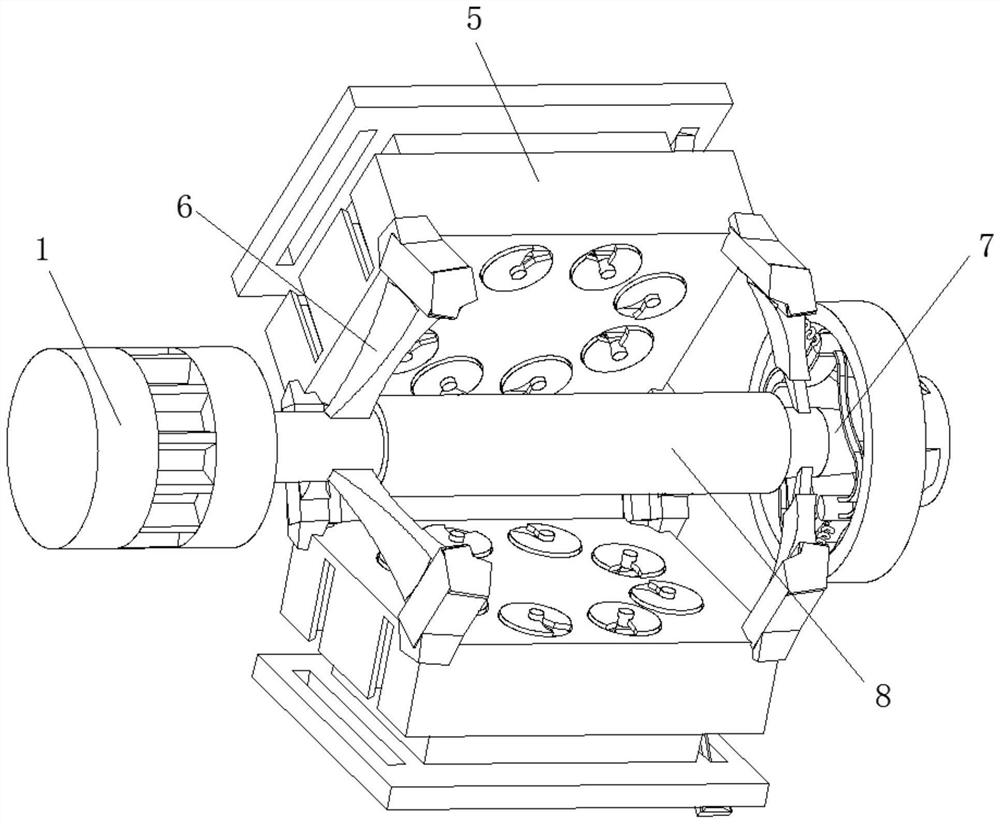

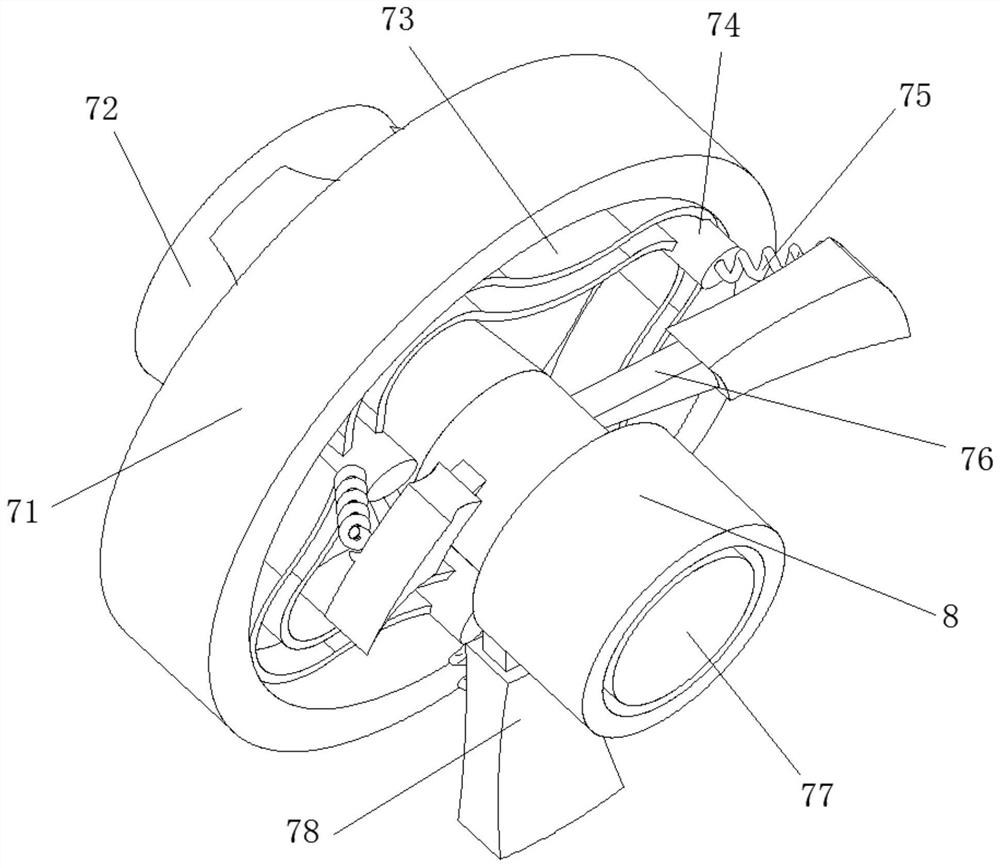

[0037] Such as Figure 1-4 As shown, the present invention provides a technical solution: a computer equipment production mold that is convenient for cooling and plasticity, including a base 2, the two sides of the top of the base 2 are fixedly connected with a support frame 3, and the tops of the support frame 3 are respectively fixed A rotating motor 1 and a rotating vibration device 7 are connected, the output end of the rotating motor 1 is fixedly connected to the left side of the rotating vibration device 7, and the outer surface of the rotating vibration device 7 is covered with a fixed shaft sleeve 4, and the rotating The outer surface of the vibration device 7 is fixedly connected with the connecting rod 6, and the side of the connecting rod 6 away from the rotary vibration device 7 is fixedly connected with the die device 5, and the rotary vibration device 7 includes a fixed collar 71, and the fixed shaft The inside of the ring 71 is fixedly connected with a corrugate...

Embodiment 2

[0047] Such as Figure 5-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the top of the die shell device 51 is provided with an upper die plate 53, and the two sides of the upper die plate 53 are provided with through holes 56, and the through hole 56 is adapted to the die housing device 51.

[0048] The inner walls on both sides of the through hole 56 are fixedly connected with an air inlet plate 54, and the lower surface of the air inlet plate 54 is provided with an air inlet groove 55, and the surface of the die housing device 51 away from the through hole 56 is A low-pressure air hole 57 is opened, and the low-pressure air hole 57 communicates with the through hole 56 through the die shell device 51 . When the die housing device 51 rotates, the air inlet groove 55 on the lower surface of the air inlet plate 54 can achieve the effect of air intake, and at the same time, the low-pressure air hole 57 has a negative pressure effe...

Embodiment 3

[0052] Such as Figure 7-8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the die housing device 51 includes a lower die groove 514, and the bottom of the lower die groove 514 is provided with a built-in A through slot 513 , the bottom of the built-in through slot 513 is fixedly connected with a fixed bottom plate 511 , and the surface of the fixed bottom plate 511 is rotatably connected with a windshield device 512 .

[0053] The windshield device 512 includes a cutaway turntable 5121, the outer surface of the cutaway turntable 5121 is sleeved inside the fixed bottom plate 511, and a windshield 5124 is fixedly connected to the top of the cutaway turntable 5121, and the windshield The side of the 5124 away from the fixed bottom plate 511 is fixedly connected with the second rotating shaft 5122 . When the air enters the interior of the built-in through-slot 513 , the wind baffle 5124 can improve the flow path of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com