Full-electric driving platform power battery rapid reloading device and reloading method thereof

A power battery and electric drive technology, applied in electric power units, power units, electric vehicles, etc., can solve the problem of short driving range of electric drive chassis, and achieve short driving range, improve power performance, and facilitate quick replacement. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

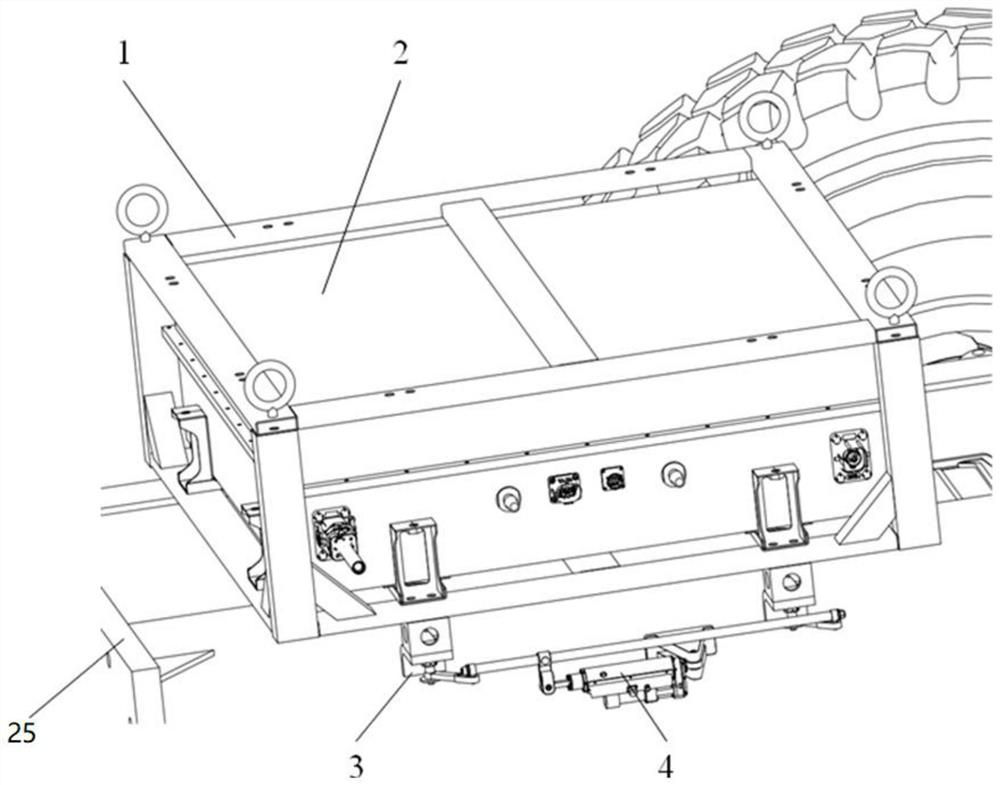

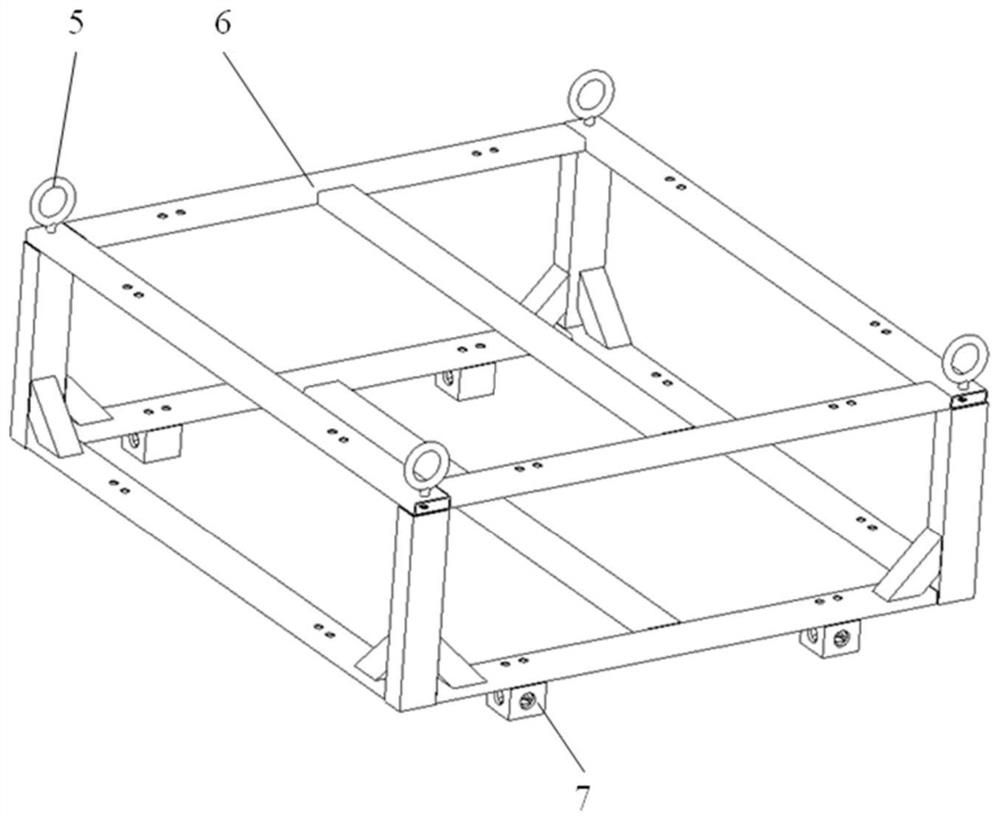

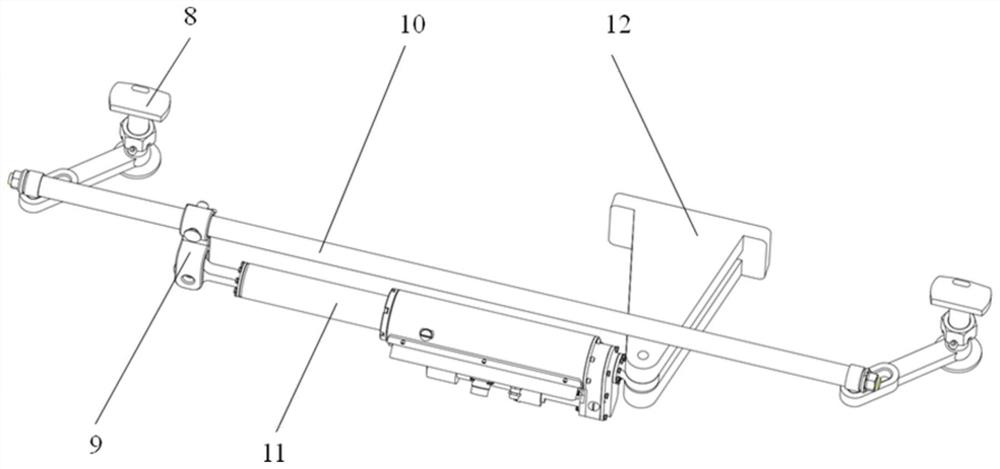

[0053] This embodiment provides a power battery quick replacement device for an all-electric drive platform, such as Figure 1 to Figure 10 As shown, the power battery quick replacement device includes an installation frame assembly 1, a twist lock support unit and an electric twist lock unit 4; the installation frame assembly 1 is provided with a power battery 2; It is fixed on the vehicle body 25; the installation frame assembly 1 includes an installation frame 6; the lower surface of the installation frame 6 is provided with four connecting seats with the same structure and correspondingly arranged in pairs, that is, the first connecting seat 7, the second connecting seat, the second connecting seat The three connecting seats and the fourth connecting seat; the electric twist lock unit 4 includes a first electric twist lock mechanism and a second electric twist lock mechanism with the same structure and correspondingly arranged.

[0054] Exemplarily, as figure 1 As shown, ...

Embodiment 2

[0076] This embodiment provides a method for quickly changing the power battery of the all-electric drive platform. The power battery quick change device for the all-electric drive platform provided in Embodiment 1 is adopted. In the daily state, the power battery 2 is arranged in the installation frame assembly 1 (the power battery 2 is installed on the vehicle body 25), such as figure 1 As shown, each connecting seat of the installation frame assembly 1 is in a locked state with the corresponding first twist lock assembly 8 and the second twist lock assembly. At this time, the first mushroom head lock block 13 and the corresponding connecting seat 7 The direction of the installation hole is vertical, and the first electric cylinder 11 is in the retracted state, such as Figure 7 shown. When the power battery 2 is insufficient and needs to be replaced quickly, the quick replacement method of the power battery 2 includes the following steps:

[0077] Step 1. Start the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com