Defrosting control method for double-unit auxiliary cooling system

A technology of auxiliary cooling system and control method, which is applied in aircraft parts, air handling equipment, transportation and packaging, etc., can solve the problems of easy generation of condensed water in the evaporator, reducing the cooling effect, and increasing the temperature in the cabin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

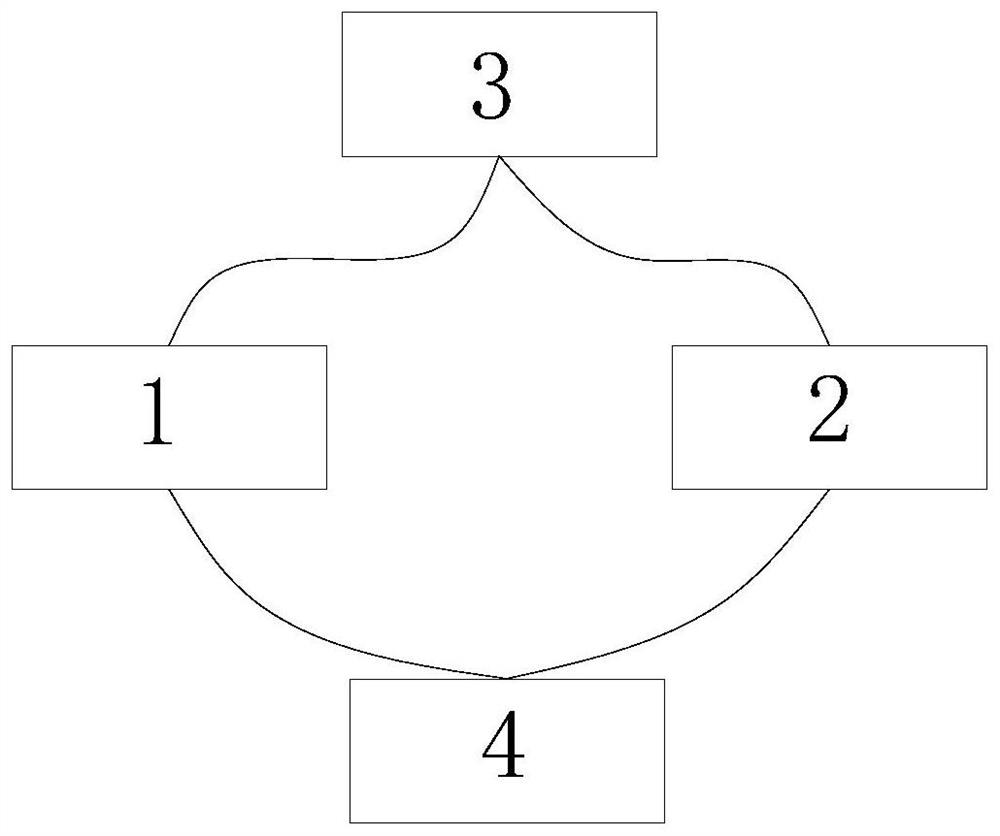

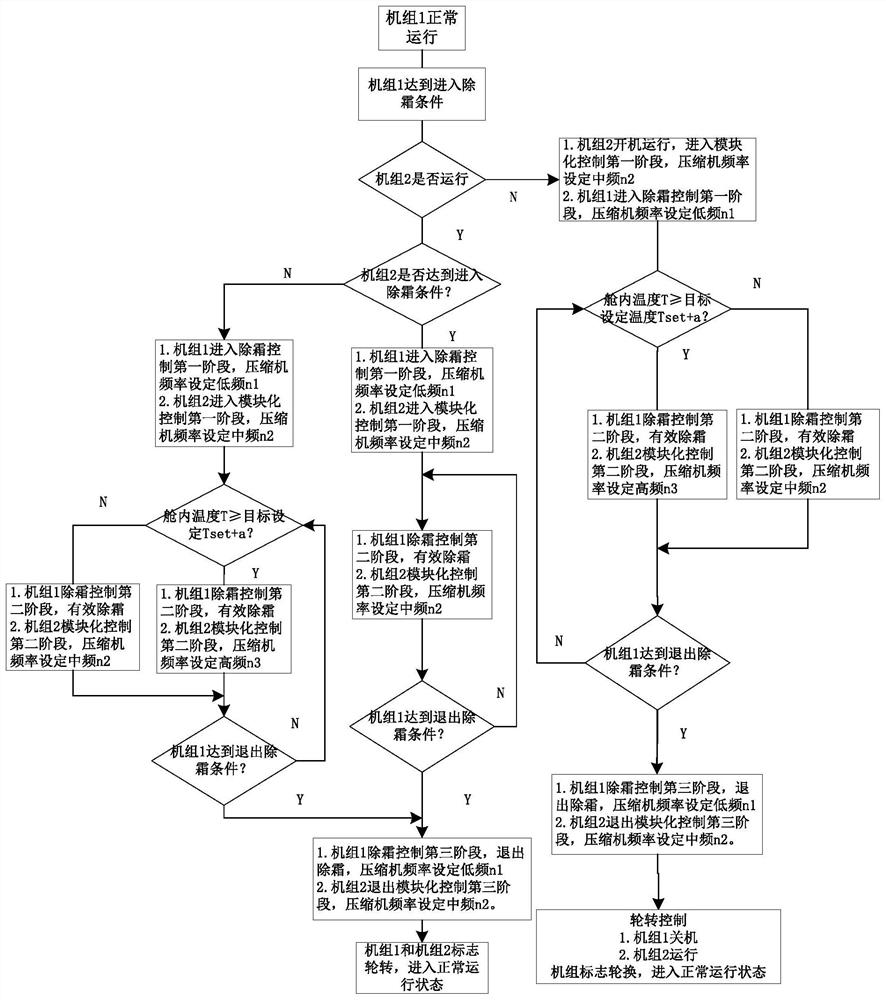

[0054] see in conjunction figure 1 and figure 2 As shown, according to the embodiment of the present application, the dual-machine auxiliary cooling system on which the operation of the defrosting control method of the dual-machine auxiliary cooling system depends includes the first auxiliary cooling unit 1, the second auxiliary cooling unit 2, the controller 3 and the cargo compartment 4, The controller 3 controls the first auxiliary cooling unit 1 and the second auxiliary cooling unit 2 to adjust the temperature of the cargo compartment 4. The defrosting control method of the dual-machine auxiliary cooling system includes: obtaining the operating status of the first auxiliary cooling unit 1; Whether the cooling unit 1 reaches the defrosting condition; when the first auxiliary cooling unit 1 reaches the defrosting condition, obtain the operating status of the second auxiliary cooling unit 2; Unit 1 and the second auxiliary cooling unit 2 are controlled.

[0055] The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com