Double-layer optical cable cross connecting cabinet with heat insulation function

A technology of thermal insulation and optical delivery box, which is applied in the field of optical delivery box, can solve the problems that affect the normal operation of optical cable lines, and the optical delivery box does not have the function of thermal insulation and heat insulation, so as to achieve the effect of improving work operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

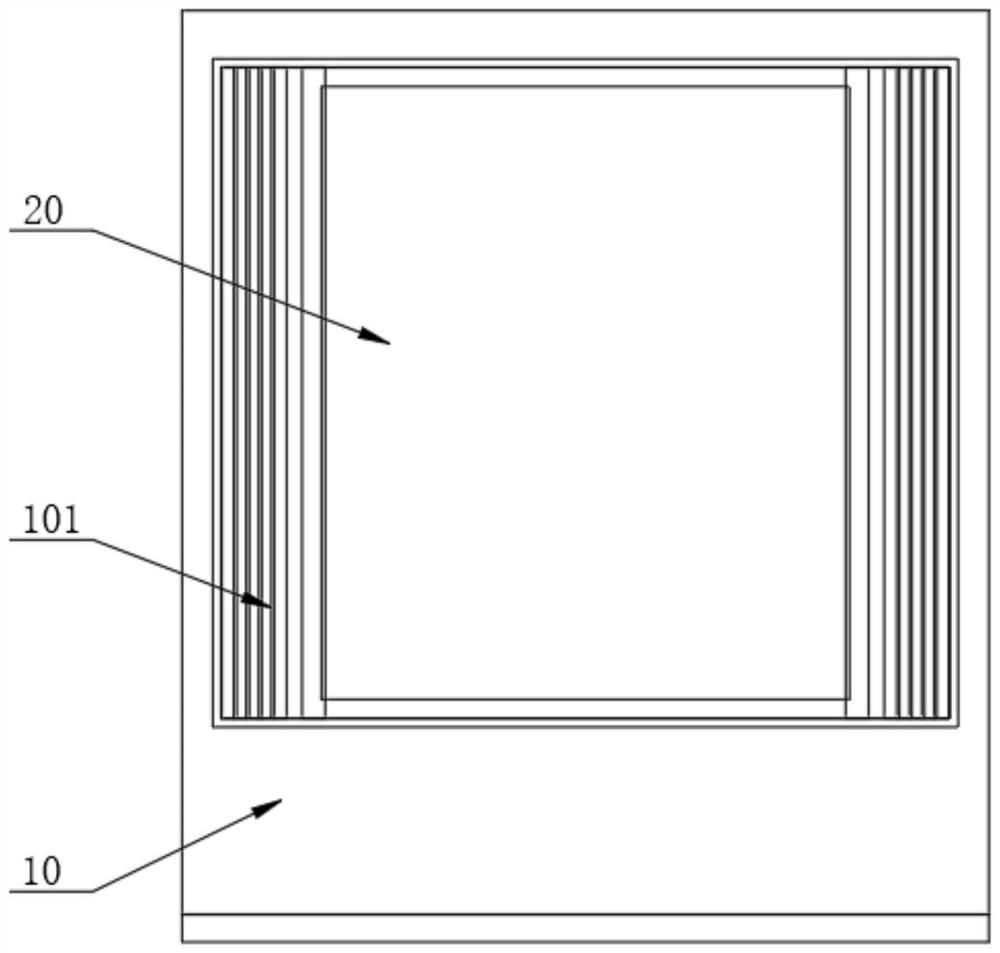

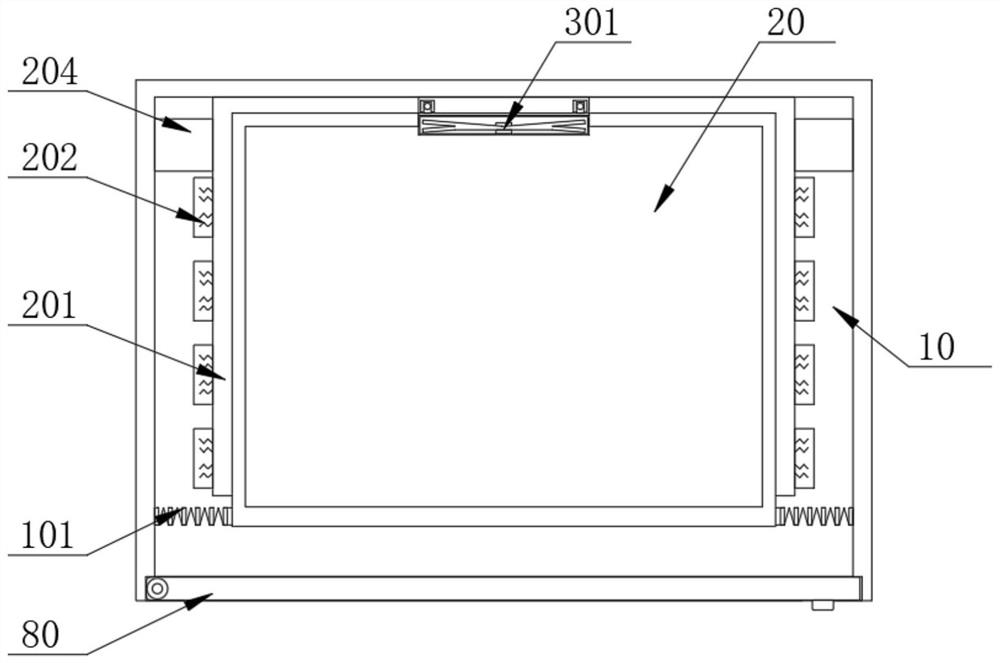

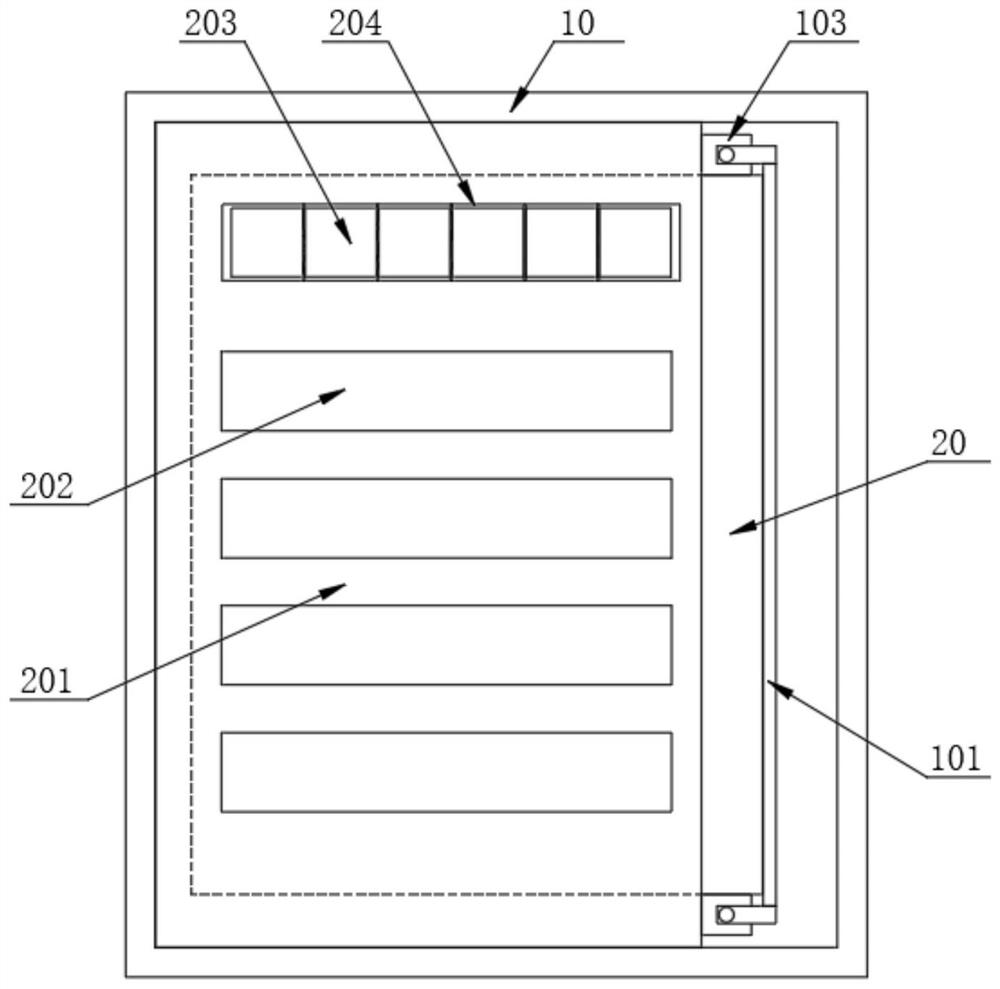

[0054] see Figure 1-6 As shown, a double-layer optical box with thermal insulation function includes an outer box 10 and an inner box 20, the inner box 20 is located inside the outer box 10, and the front of the outer box 10 is hinged. The box door 80 is hinged, and by arranging the optical cable lines inside the inner box body 20, the waterproof performance and the anti-collision performance of the optical cable lines are effectively improved by utilizing the joint work of the outer box body 10 and the inner box body 20. Both sides of the front of the inner box body 20 are provided with airtight mechanisms, and the peripheral surface of the inner box body 20 is provided with a thermal insulation mechanism, the inside of the inner box body 20 is sealed by the airtight mechanism, so that the inside of the inner box body 20 forms a closed space , and then effectively improve the thermal insulation effect of the inner box body 20 internal optical cable lines, while utilizing the...

Embodiment 2

[0060] see Figure 6 As shown, the interior of the inner box body 20 in the present invention is provided with a processor, and the processor is connected with an acquisition module, a temperature analysis module, an environment detection module, a data storage module, an alarm module and a controller, and the output terminal of the controller is connected to the servo The input ends of the electric cylinder 103, the electric heating block 202, the semiconductor cooling plate 203, the cooling fan 301, and the electric push rod 305 are electrically connected, and the acquisition module is used for the inside of the outer box 10, the outside of the inner box 20, and the inner box The internal ambient temperature data of 20 is collected, and the data storage module is used to store the collected data;

[0061] Wherein the acquisition module includes a first temperature sensor 50, a second temperature sensor 60, and a third temperature sensor 70, and the first temperature sensor 5...

Embodiment 3

[0079] see Figure 1-6 As shown, the present invention also discloses a method for using a double-layer light box with thermal insulation function, which specifically includes the following steps:

[0080] The first step, through the first temperature sensor 50, the second temperature sensor 60 and the third temperature sensor 70, carry out real-time monitoring of the ambient temperature inside the outer box 10, the inner box 20, and the working temperature data value of the optical cable line;

[0081] In the second step, the ambient temperature R2 inside the inner box body 20 is respectively compared with the ambient temperature R1 inside the outer box body 10 and the maximum normal working environment temperature range Rxmax and the minimum normal working environment temperature range Rxmin of the normal working environment temperature range Rx In comparison, when R2<R1, and R2≥Rxmax, it is determined that the ambient temperature inside the inner box 20 is too high, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com