Gas-liquid-solid three-phase flow simulation method

A simulation method, gas-liquid-solid technology, applied in the field of hydraulic simulation, can solve the problem of not being able to truly simulate the real movement of particles in the hydraulic oil tank, not fully considering the shape, size and force of the particles, and not being able to accurately display and predict the final state of the particles. Problems such as deposition position, to achieve intuitive and easy-to-understand simulation results, short simulation cycle, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0054] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, and are not exhaustive of all the embodiments. And in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

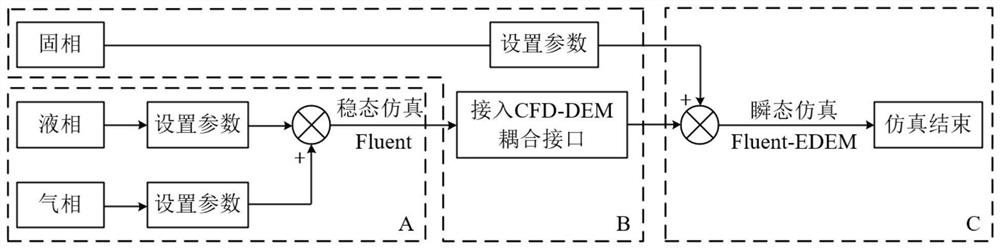

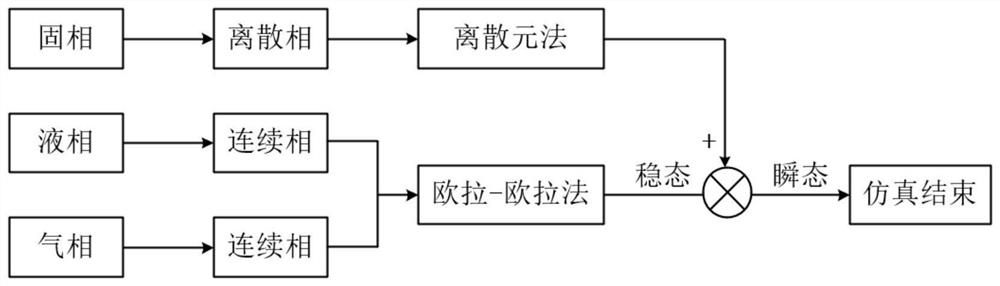

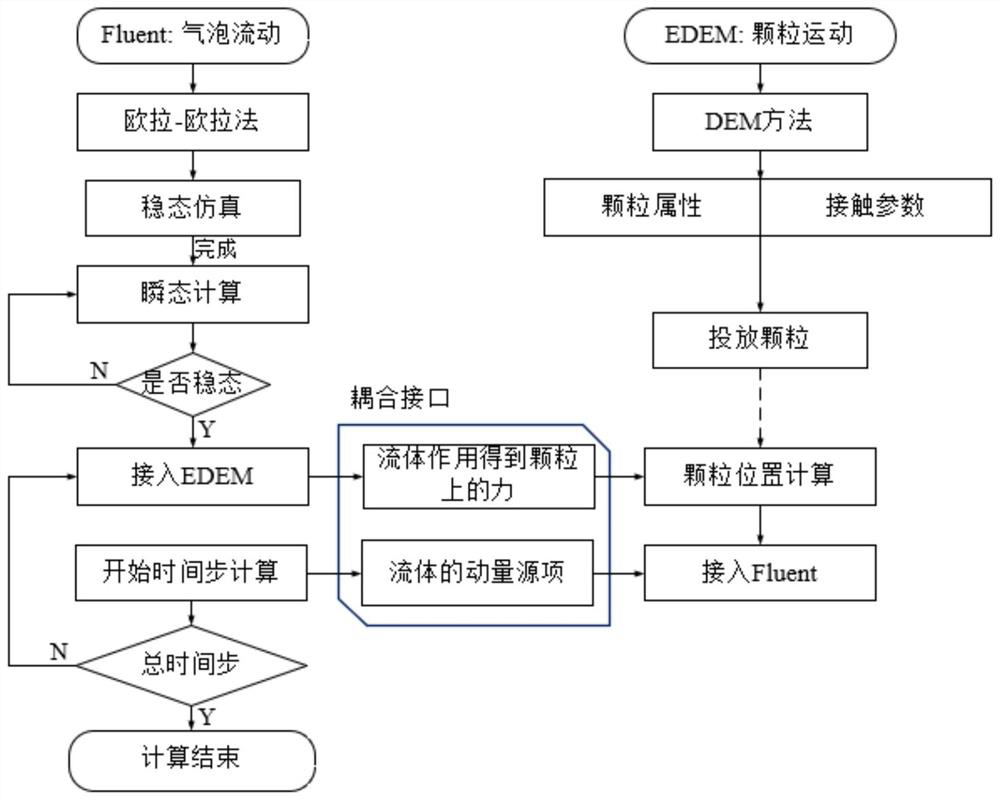

[0055] figure 1 and figure 2 Schematically shows a gas-liquid-solid three-phase flow simulation method according to an embodiment of the present invention, comprising the following steps:

[0056] Step S1: The liquid phase and the gas phase are subjected to steady-state simulation in the simulation software FLUENT. The gas-liquid simulation adopts the Euler-Euler model, and both the gas phase and the liquid phase are regarded as continuous phases, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com