Hardware profile forming method and device

A molding device and molding method technology, which is applied in the field of hardware profile molding methods and devices, can solve the problems of low output demand and expensive production costs of triangular pipes, improve appearance quality, solve output and expensive production costs, and make the equipment small and portable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

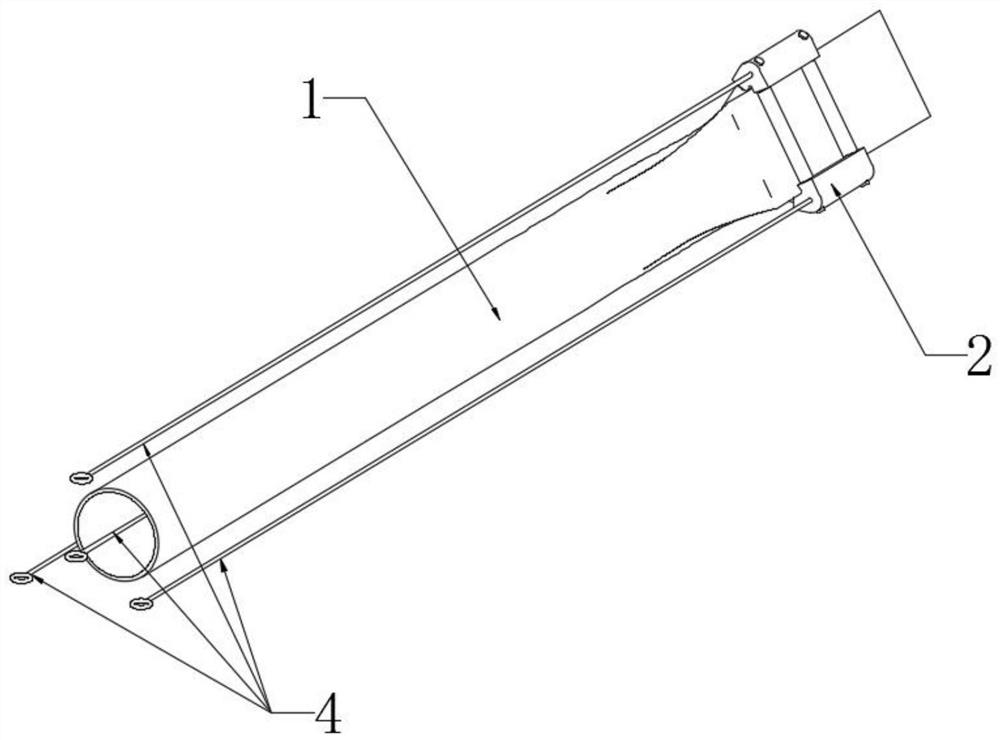

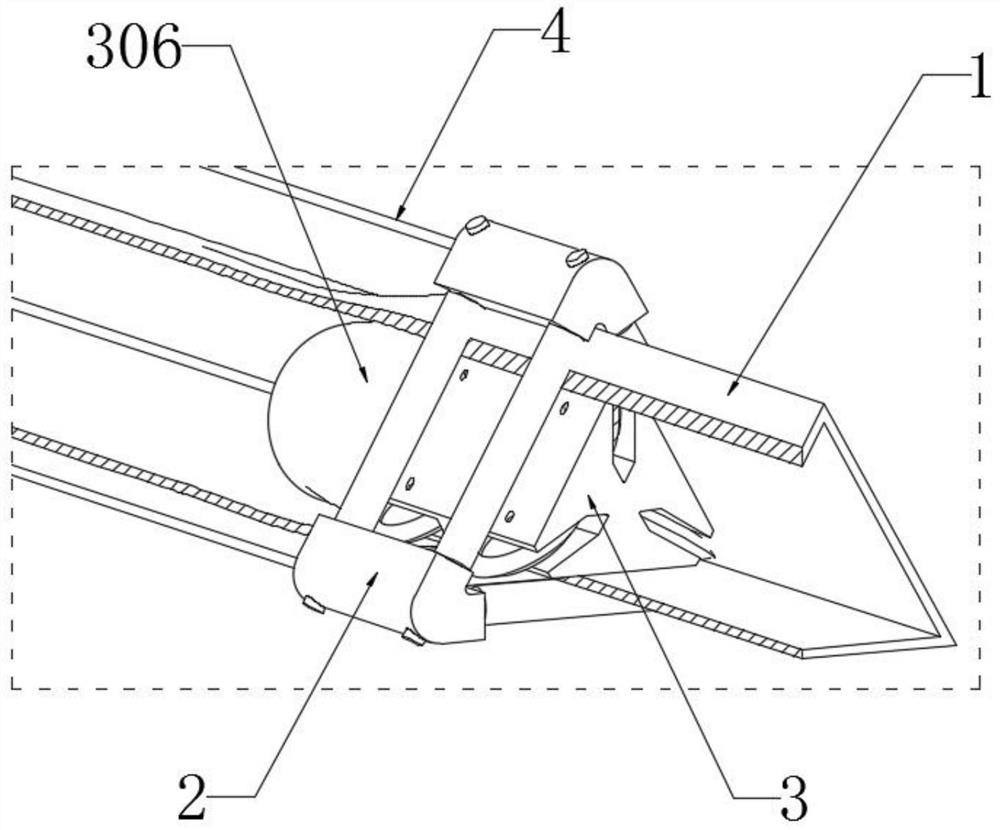

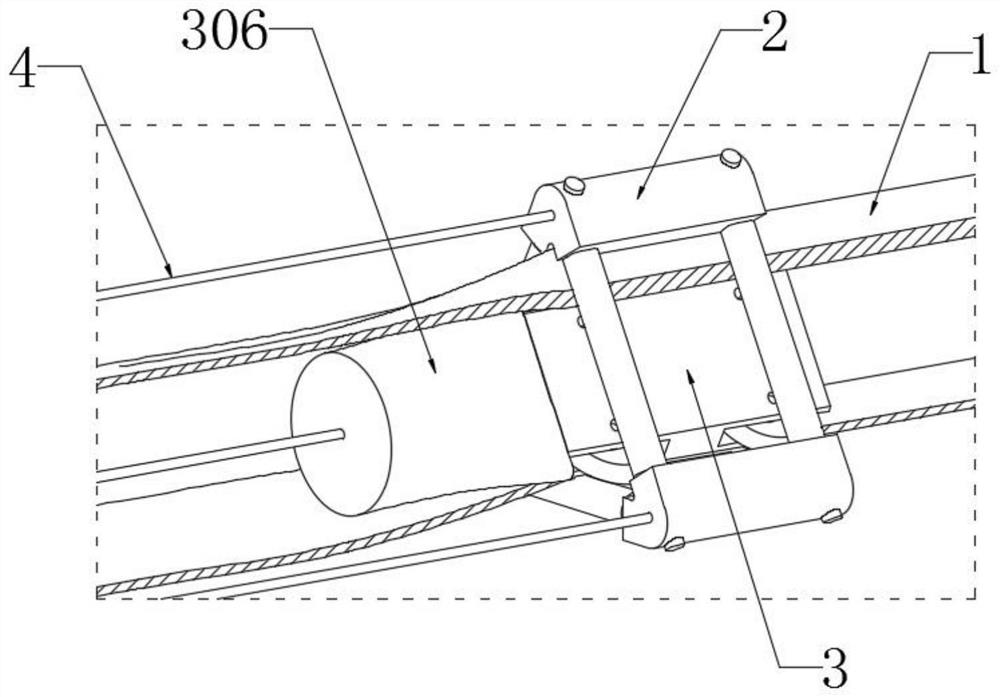

[0035] refer to Figure 1-Figure 8 , a metal profile forming device, including a pipe 1 for triangular pipe production, the pipe 1 is covered with an outer extruding mechanism 2, and the outer extruding mechanism 2 is used to flatten the side wall of the triangular pipe, and the The outer extruding mechanism 2 is a triangular shaft rolling structure, which includes a connecting block 201 and a roller 202. The inner extruding mechanism 3 is sleeved inside the pipe material 1, and the inner extruding mechanism 3 is used for triangular The corners of the tube are formed, and the inner extrusion mechanism 3 is a triangular wheel rolling structure, which includes a mounting seat 301 and an extrusion wheel 304;

[0036] The device fully considers the cost of production equipment and the cost of learning the skills of operators. The inner extrusion mechanism 3 and the outer extrusion mechanism 2 can be used to shape the common stainless steel thin-walled round tubes to obtain triangu...

Embodiment 2

[0044]A metal profile forming method, applied to the above-mentioned device, said method comprising the following steps:

[0045] S1. Prepare a stainless steel thin-walled round pipe as the raw material pipe 1, and use tooling to support one end of the pipe 1, so that the subsequent use of the inner extrusion mechanism 3 and the outer extrusion mechanism 2 can be used for spinning under the pull of the cable 4;

[0046] S2. Pass the cable 4 connected to the shaping block 306 through the pipe material 1, pull the cable 4 so that the round end of the shaping block 306 is inserted into the pipe material 1, and continue to pull the cable 4 relative to the pipe material 1, so that the pipe material 1 is located in the inner extrusion The part in front of the movement direction of the mechanism 3 initially obtains an approximately triangular outline under the extrusion of the shaping block 306, and the inner extrusion mechanism 3 has not yet fully entered the pipe 1;

[0047] S3. Ap...

Embodiment 3

[0050] The difference from Example 1 is that when the requirements for the edge shape of the triangular tube are relatively low, only the outer extruding mechanism 2 can be used for the final rolling operation, and the obtained edge of the triangular tube will have obvious radians.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com