High-safety new energy vehicle chassis structure

A new energy vehicle, high safety technology, applied in the field of high safety new energy vehicle chassis, can solve the problem of low anti-collision performance, and achieve the effect of improving anti-collision performance and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

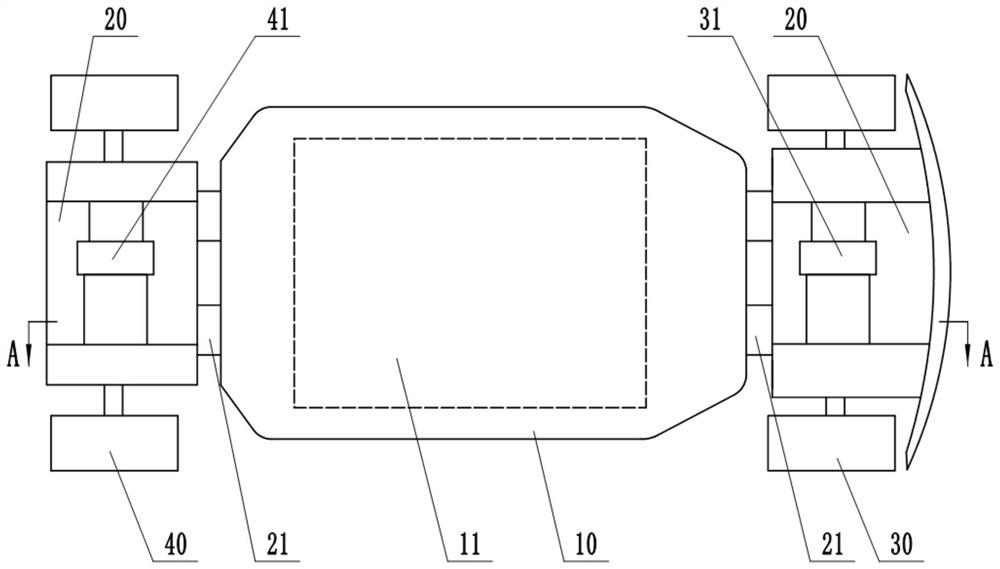

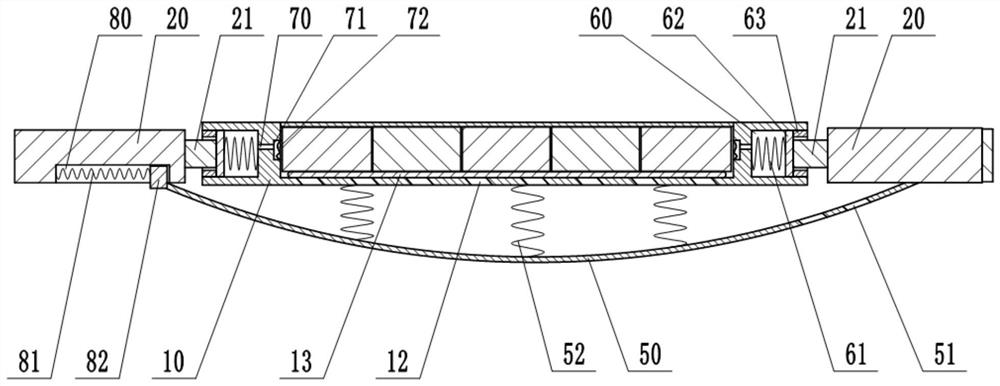

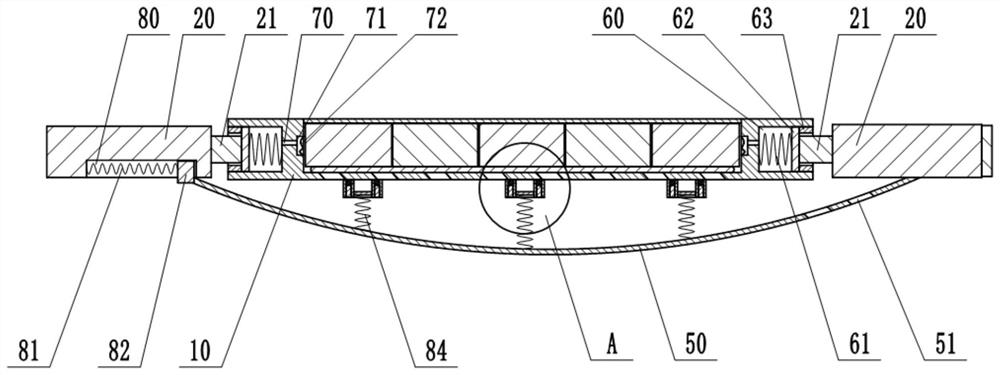

[0023] This embodiment is basically as figure 1 , figure 2 Shown: a high-safety new energy vehicle chassis, including a chassis main board 10, an anti-drag module and installation modules located at the front and rear ends of the chassis main board 10, and a battery installation slot 11 for installing a battery is opened in the chassis main board 10, The chassis main board 10 is provided with a cover plate capable of closing the battery installation slot 11 . Two buffer tanks 60 are opened in the front and rear sides of the chassis main board 10, and the buffer tanks 60 are filled with a buffer fluid, which is hydraulic oil in this embodiment. A piston 62 is slidably and sealed in the buffer tank 60 . The inner wall of the buffer tank 60 is welded with a stopper 63 for preventing the piston 62 from breaking away from the buffer tank 60 . The buffer groove 60 is provided with a first elastic member 61 (the first elastic member 61 in this embodiment is a compressible spring),...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that: image 3 , Figure 4 As shown, the structure of the buffer is different. In this embodiment, the buffer includes a third elastic member 91 (the third elastic member 91 in this embodiment is a spring) and a fixing cylinder 90 welded on the chassis main board 10 . The interior of the fixed cylinder 90 is filled with hydraulic oil, and a sliding plug 95 is slid and sealed in the fixed cylinder 90 . The upper end of the third elastic member 91 is connected to the sliding plug 95 , and the lower end of the third elastic member 91 abuts against the elastic steel plate 50 . The side wall of the fixed cylinder 90 is provided with an annular sliding groove 92 facing the side of the elastic steel plate 50, and the inner wall of the fixed cylinder 90 is provided with a channel 93 communicating with the annular sliding groove 92, and the hydraulic oil in the fixed cylinder 90 can pass through the channel 93. into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com