Machine-made sand void ratio online measurement system and method based on double cameras

A technology of machine-made sand and porosity, which is applied in measurement devices, machine learning, permeability/surface area analysis, etc., can solve the problems of complicated methods, errors, and low measurement efficiency in measuring porosity, so as to improve detection accuracy and efficiency, Realize the effect of online detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

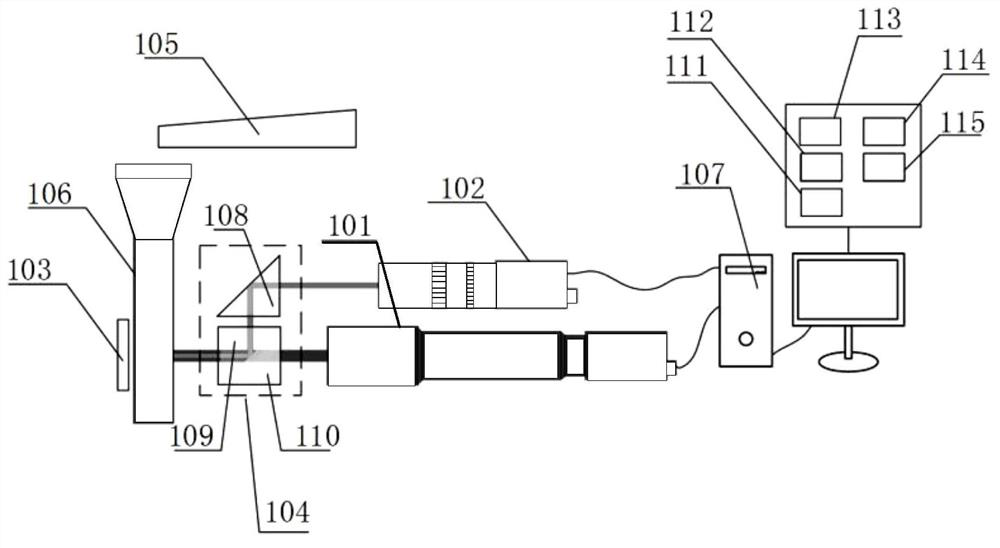

[0059] This embodiment provides an on-line measurement system for the porosity of machine-made sand based on dual cameras, such as figure 1 As shown, the system includes a basic CCD camera 101, a precision CCD camera 102, an LED backlight 103, a prism group 104, a vibrating feeder 105, a transport tube 106 and a terminal 107 (such as a computer), and the basic CCD camera 101 and Precision CCD camera 102 is connected with terminal 107 respectively, and described vibration feeder 105 is positioned at the top of transmission pipe 106, and described prism group 104 is positioned between transmission pipe 106 and two cameras (101 and 102);

[0060] The basic CCD camera 101 is used to photograph the falling area of the whole machine-made sand, and the precision CCD camera 102 is used to photograph a part of the falling area of the whole machine-made sand, and the fine particles that the basic CCD camera 101 cannot measure are compensated by the precision CCD camera 102 ;

[006...

Embodiment 2

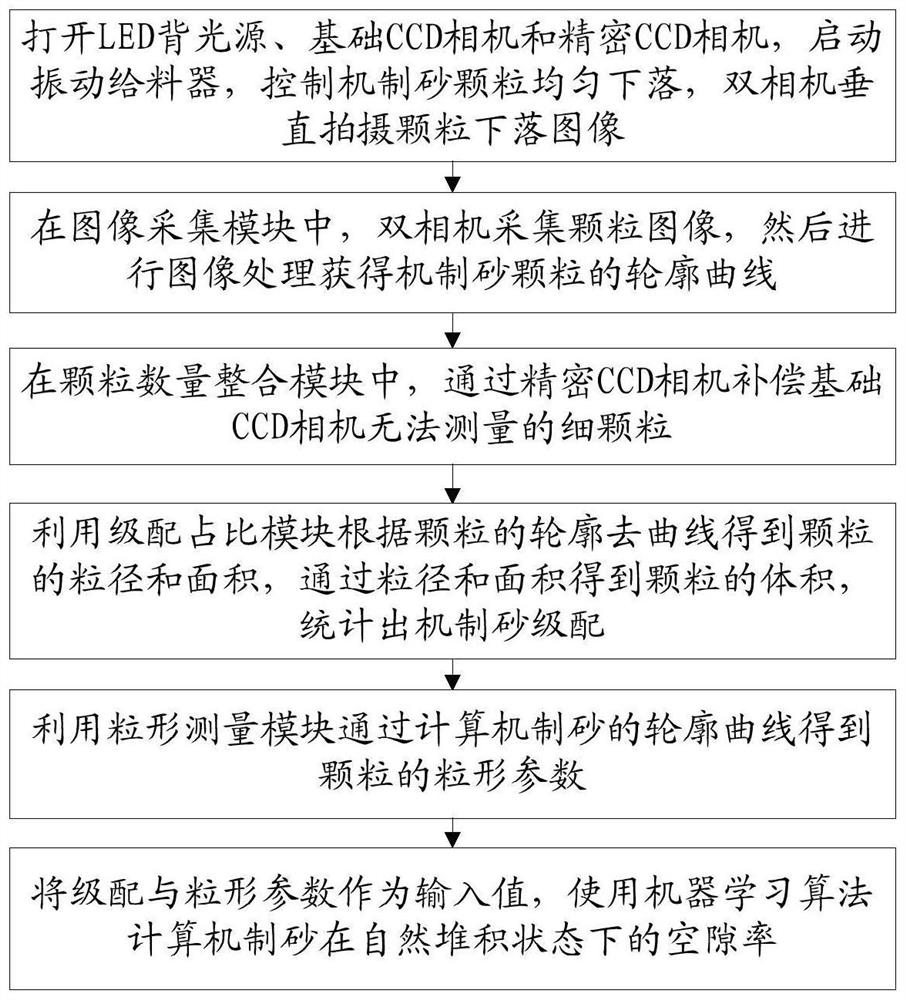

[0074] see Figure 1 to Figure 4 , a dual-camera-based online measurement method for the porosity of machine-made sand according to the present invention needs to provide the system as described in Embodiment 1, and the method includes the following steps:

[0075] Step 1. Turn on the LED backlight, basic CCD camera and precision CCD camera, start the vibrating feeder, control the mechanism of sand particles to fall evenly, and take pictures of the particles falling vertically with the dual cameras; refer to image 3 , the measurement principle of dual cameras, when the machine-made sand particles pass in front of the LED light source, the basic CCD camera obtains the image of the entire field of view, and the precision CCD camera obtains the image of the center part of the field of view after being refracted by the prism, so that the precision CCD camera can compensate the inability of the basic CCD camera Measured fine particles;

[0076] Step 2, in the image acquisition mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com