Fifteen-phase asynchronous motor rotor broken bar number high-precision diagnosis method based on ESPRIT-PSA and LGBM

A technology of rotor broken bars and diagnosis method, which is applied in the field of fault diagnosis and can solve problems such as the deviation of the number of broken bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The present invention proposes a method for diagnosing the number of broken bars of a 15-phase asynchronous motor rotor based on ESPRIT-PSA and LGBM, and the diagnostic accuracy of the method is as high as 99.38%. The feature of the present invention is to apply ESPRIT-PSA to instantaneous reactive power fault component amplitude A q The extraction of and LGBM-based model training are described in detail below.

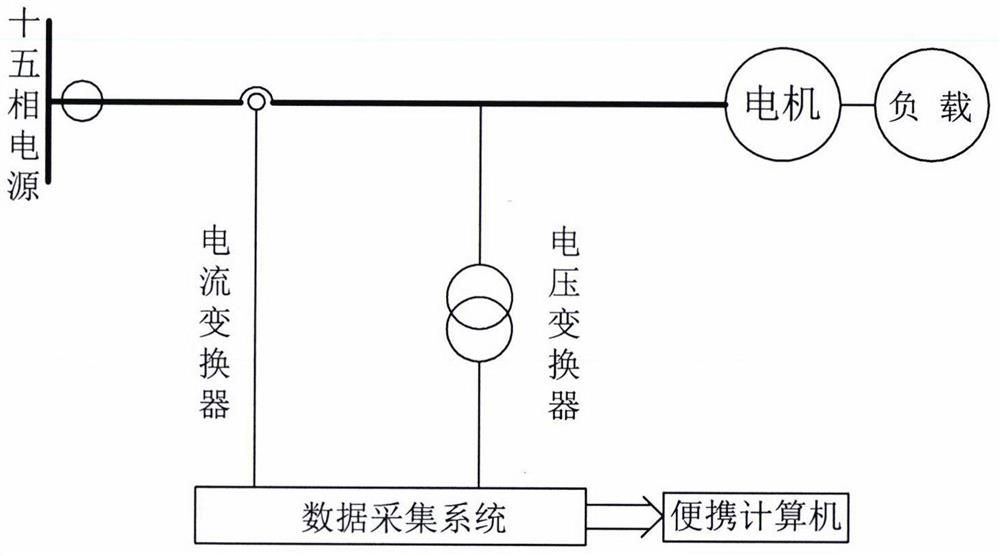

[0104] figure 1 Wiring diagram for the experiment. Among them, the experimental motor is a fifteen-phase asynchronous motor with a rated voltage of 380V, a rated power of 5.5kW and a rated frequency of 50Hz. In order to carry out the rotor broken bar test, in addition to the normal rotor, two faulty rotors (drilled on the guide bar at a distance of 10 mm from the end ring, with a depth of 15 mm and a diameter of 10 mm) are used to simulate the broken bar fault. There is one broken bar and two consecutive broken bars in the two faulty rotors respectively. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com