Sewage treatment system for manufacturing decorative printing paper

A sewage treatment system, technology of printing paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

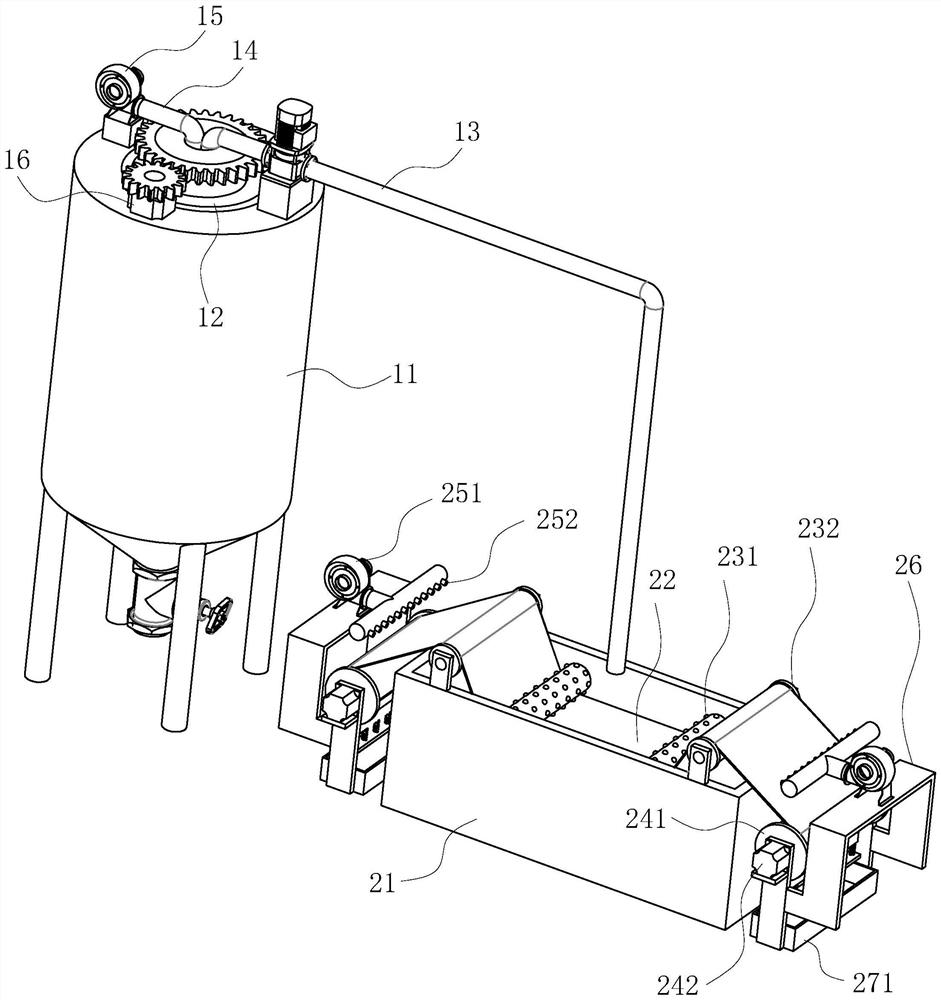

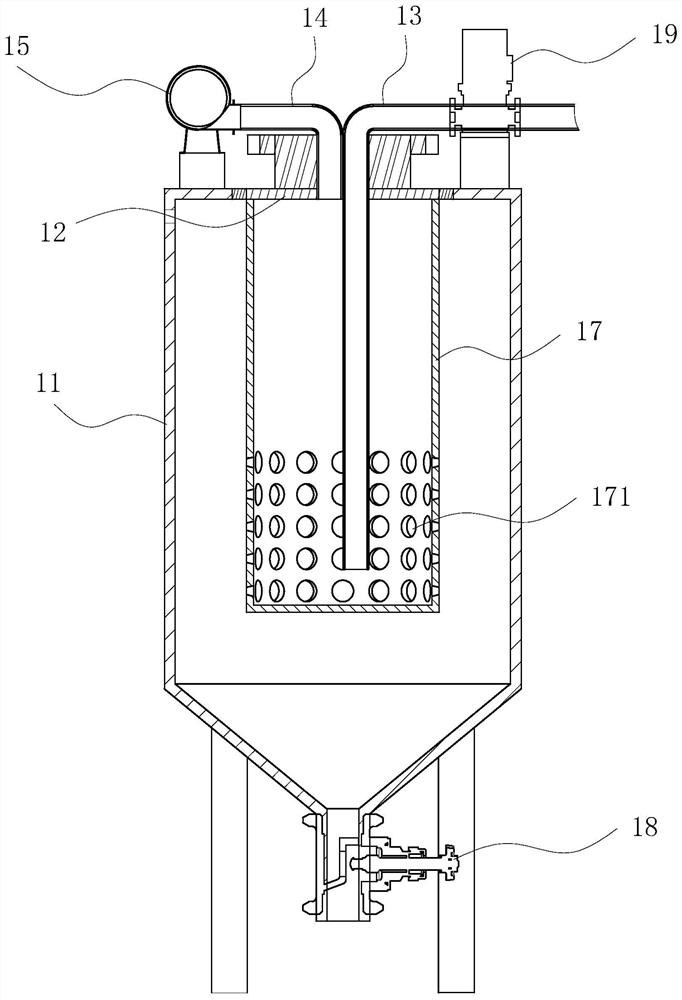

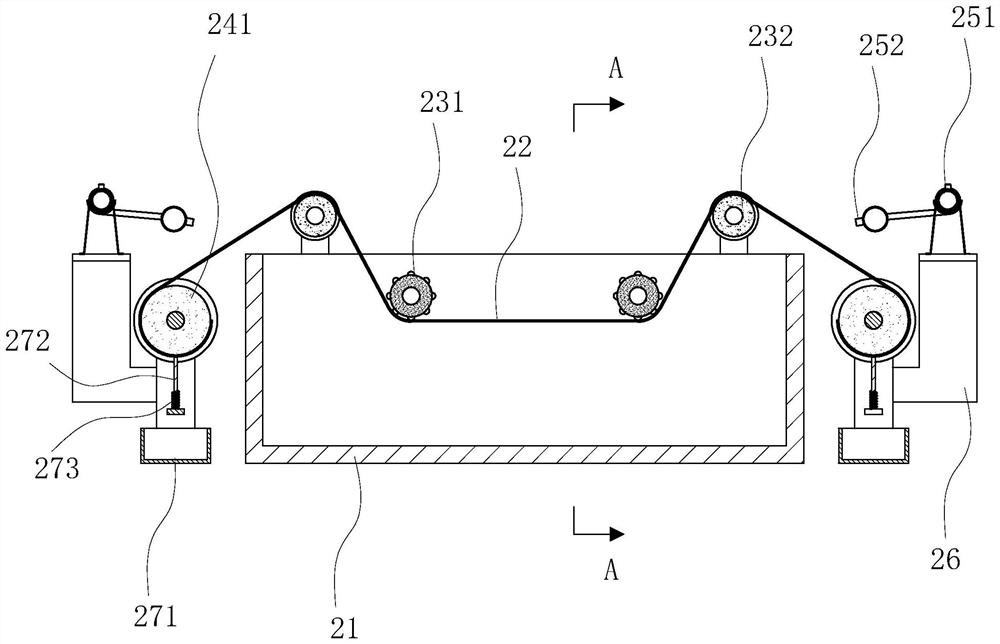

[0033] The following is attached Figure 1-5 The application is described in further detail.

[0034] The embodiment of the present application discloses a sewage treatment system made of decorative printing paper. refer to figure 1 A sewage treatment system made of decorative printing paper includes a filter tower and a filter tank, the filter tower is connected with a water inlet pipe and a drain pipe 13, the water inlet pipe is connected with a sewage source, and the drain pipe 13 is connected with the filter tank. The printing sewage enters the filter tower from the water inlet pipe, and performs the first filtration in the filter tower to filter out the large particles in the sewage, and the sewage filtered for the first time is discharged to the filter pool through the drain pipe 13 for the second filtration , the second filtration filters out the fine particles in the sewage, and the sewage filtered twice is then passed on to the next treatment process.

[0035] refe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap