Spraying nozzle and spraying method

A spray head and air spray head technology, which is applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of poor atomization effect, large pressure fluctuation, unstable powder suction state, etc., and achieve good atomization effect, small pressure fluctuation, The effect of powder absorption stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

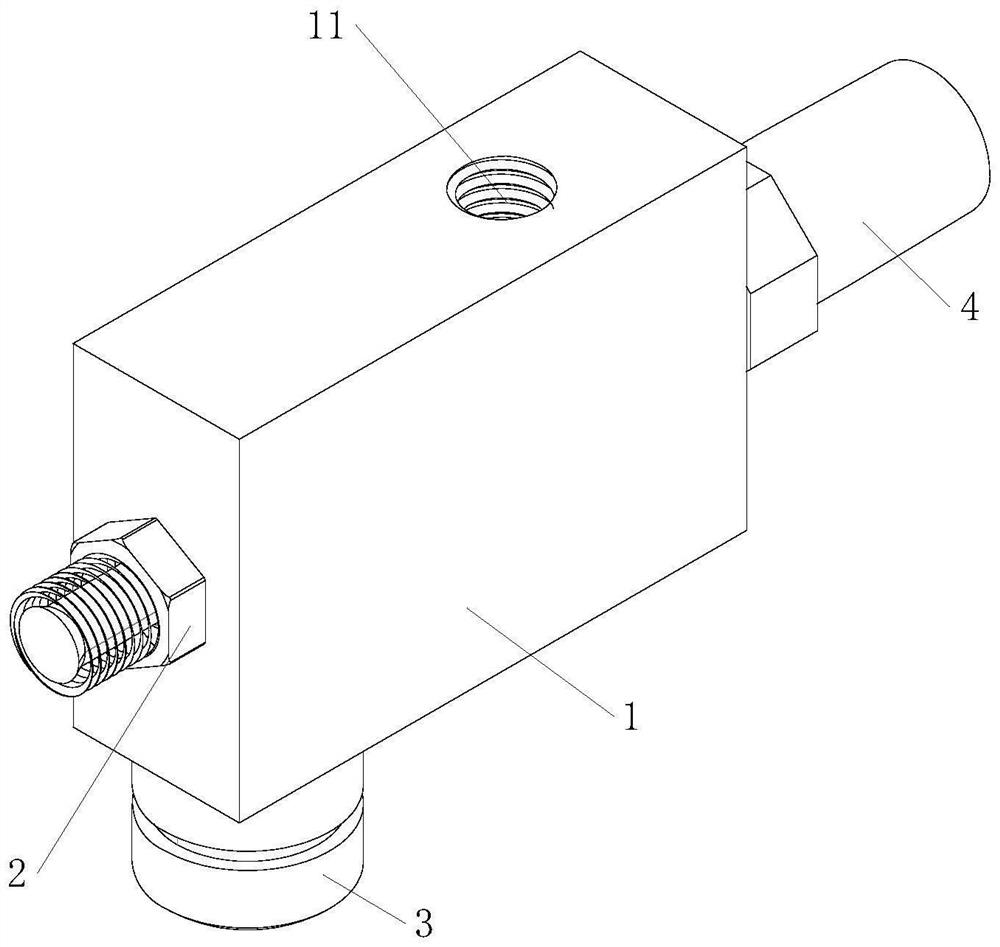

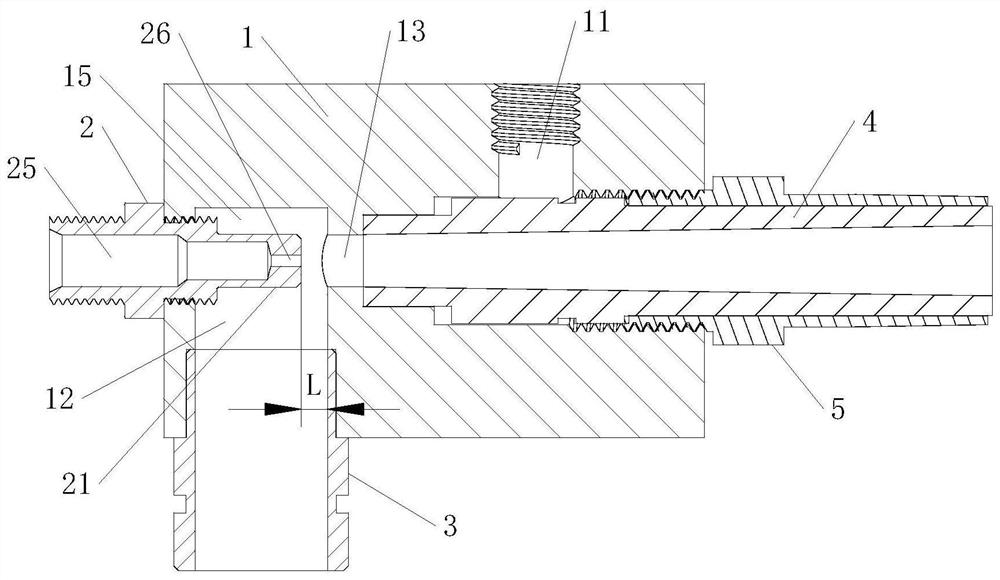

[0022] Such as Figure 1 to Figure 4 As shown, a spray nozzle includes a powder outlet pipe 4 , a valve body 1 and an air inlet nozzle 2 . The powder outlet pipe 4 is a Venturi tube, which can accurately control the gas flow.

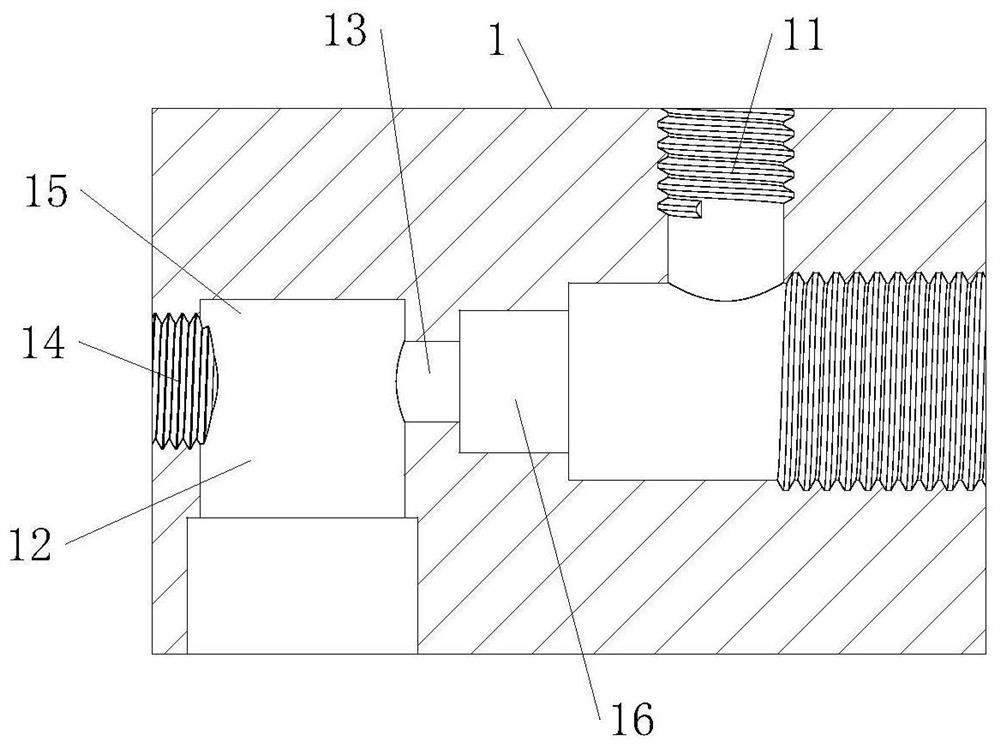

[0023] The bottom of the valve body 1 is provided with a powder inlet hole 12, which is connected to the powder bucket through the powder inlet joint 3; the two ends of the valve body 1 are respectively provided with a main air inlet connection hole 14 and a throat hole 16, and a powder outlet pipe 4 is fixed on the throat pipe hole 16, the main air inlet connection hole 14 communicates with the powder inlet hole 12, and one side of the powder inlet hole 12 is also provided with a powder outlet hole 13, and the powder outlet hole 13 communicates with the powder outlet pipe 4, and the main inlet The air connection hole 14, the powder outlet hole 13 and the powder outlet pipe 4 are coaxially arranged.

[0024] The air inlet nozzle 2 is provided with a h...

Embodiment 2

[0030] A spraying method, the high-pressure gas sprayed by the air spray head 21 directly enters the powder outlet hole 13, and an annular airflow is formed between the end of the air spray head 21 and the powder outlet hole 13 to suck the powder or liquid into the powder outlet pipe 4 ; Adjust the negative pressure of the powder outlet hole 13 through the auxiliary air inlet connection hole 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com