Novel paint spraying tool for paint spraying of oil storage cylinder assembly of shock absorber

A technology of oil storage tanks and shock absorbers, which is applied in the direction of injection devices, etc., can solve the problems of multiple operating procedures, short life cycle, long time, etc., and achieve the effects of reducing operating procedures, good shielding, and convenient production change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

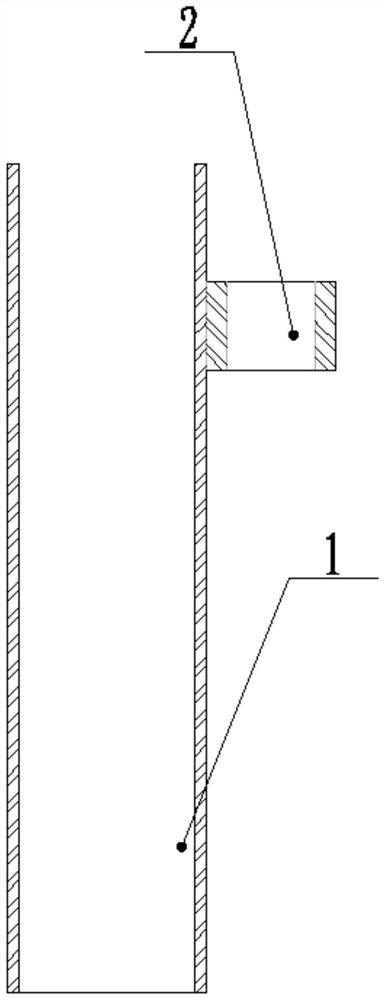

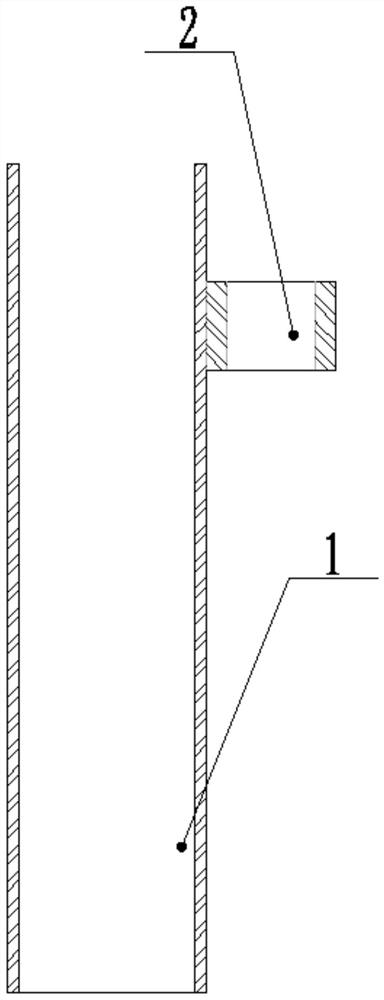

[0029] Such as figure 1 As shown, the present invention proposes a new type of painting tooling used for painting the shock absorber oil storage cylinder assembly, including a shielding tube tooling, the shielding tube tooling includes a shielding tube 1 and a hook 2, and the shielding tube 1 is used to place the storage tank As for the piston rod part of the oil cylinder, the hook 2 is adapted to be manufactured by a hanger, and is used to keep the new painting tooling stable in the work process.

[0030] The hook 2 of the present invention is arranged on the top outer wall of the shielding tube 1 .

[0031] The shielding pipe 1 of the present invention is made of a tight steel pipe to prevent the surface of the piston rod from being scratched. The top of the shielding tube 1 is open. The top of the shielding tube 1 is polished and smooth. The bottom of the shielding tube 1 is sealed. The inside of the shielding tube 1 uses the working principle of pressure to shield the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com