A hydraulic jet oscillator element

A technology of hydraulic jet and oscillator, applied in the direction of spraying device, liquid spraying device, etc., to achieve the effects of increased oscillation amplitude, easy frequency control, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, detailed description will be given below with reference to the accompanying drawings and specific embodiments.

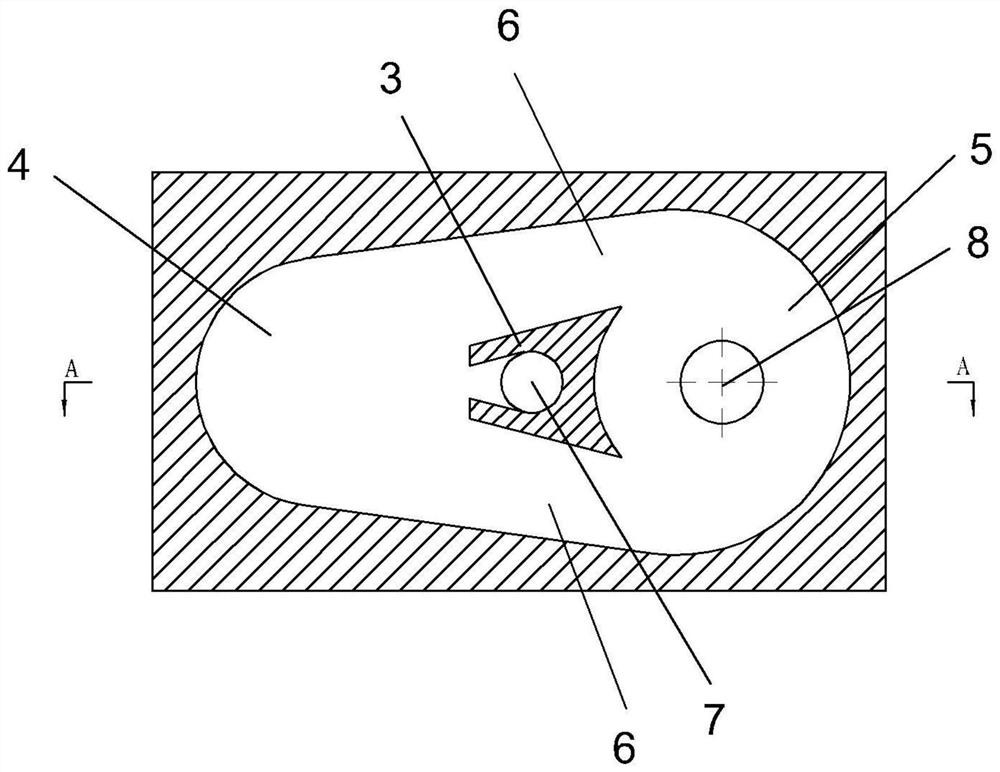

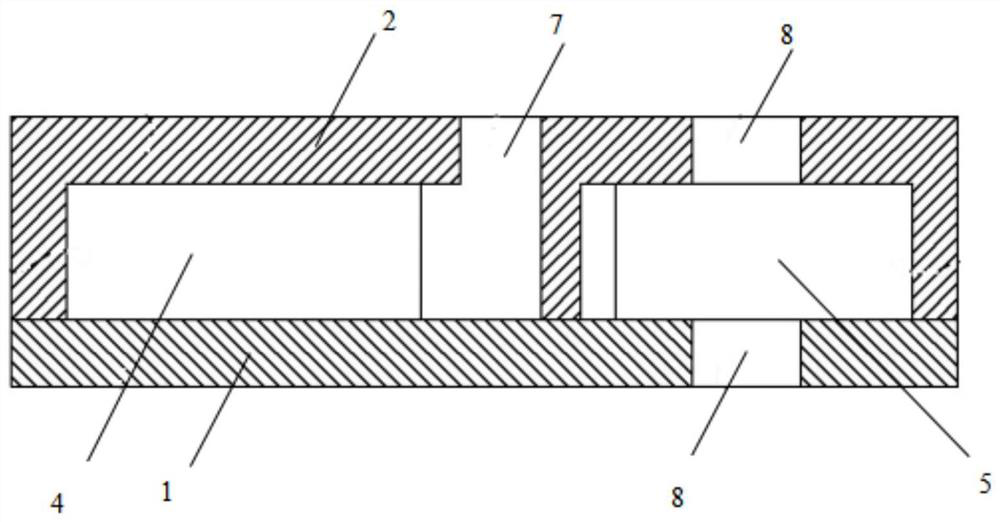

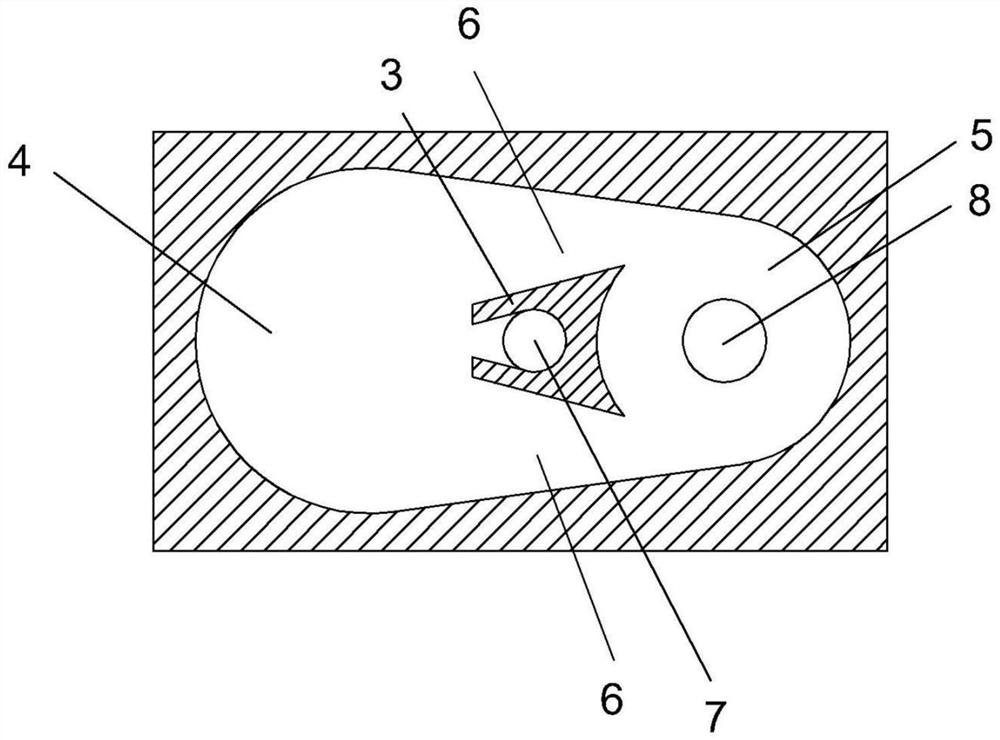

[0026] like figure 1 and 2 As shown, the embodiment of the present invention provides a hydraulic jet oscillator element, which includes a cover plate 1, a base plate 2 and a side wall, the base plate 2, the cover plate 1 and the side wall form a cavity, and a cavity is also provided in the cavity The jet member 3 divides the cavity into an oscillating cavity 4 , a vortex cavity 5 and an output channel 6 , wherein the output channel 6 is formed by the jet member 3 and the side wall, and its function is to communicate the oscillating cavity 4 and the vortex cavity 5 .

[0027] The jet member 3 includes a semi-closed groove for fluid flow, the opening direction of the semi-closed groove is toward the oscillating cavity 4, and the vortex ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com