Motor accessory production mold facilitating material taking

A technology for convenient picking and accessories, which is applied in the direction of electrical components, electric components, and motor generators, etc., can solve the problems of slow material picking process, achieve the effect of increasing the speed of material picking, improving creativity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

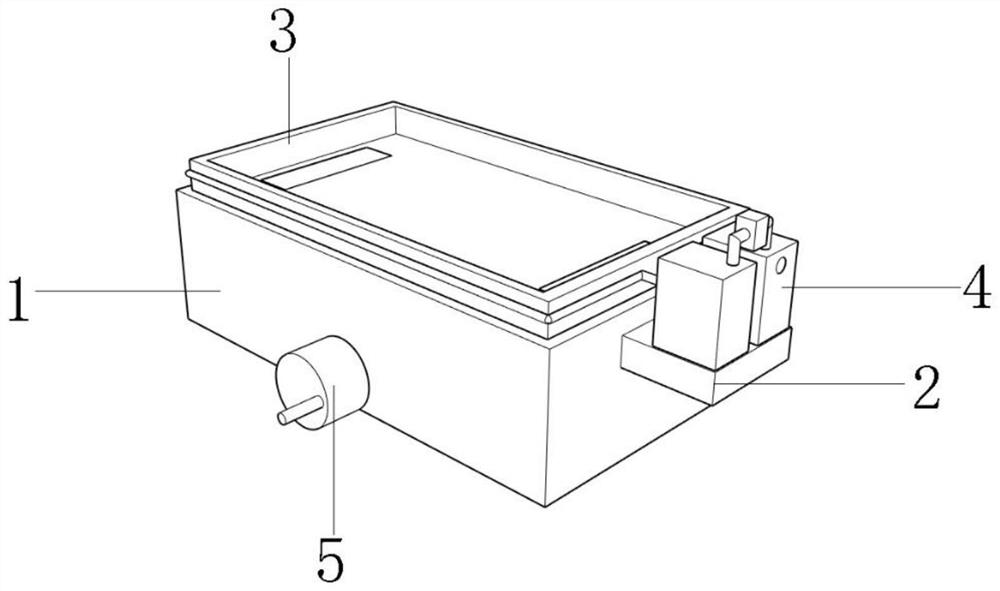

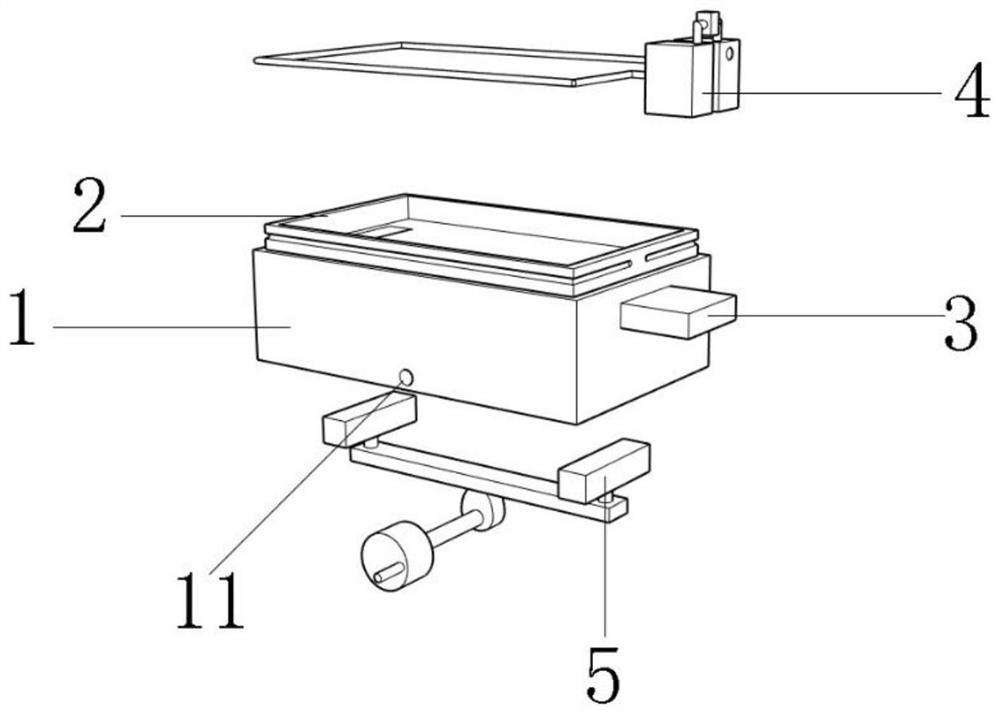

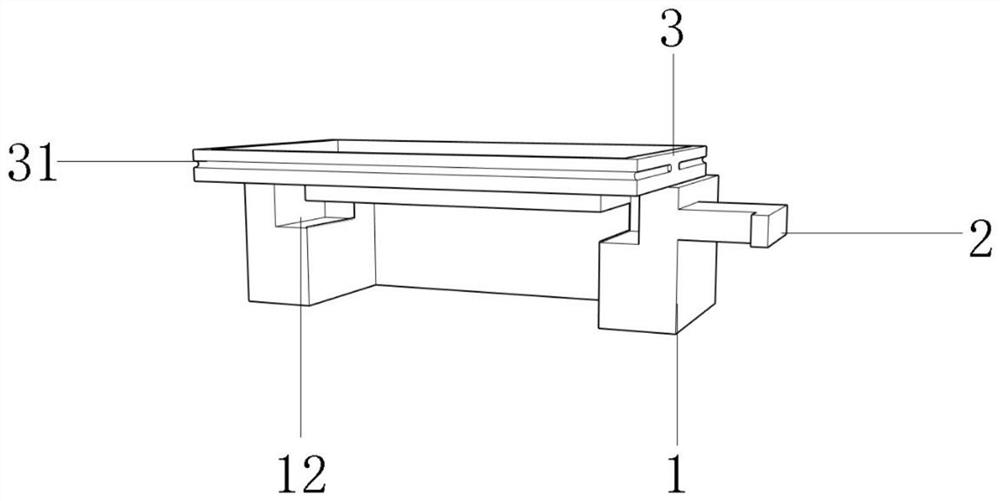

[0022] as attached figure 1 to attach Figure 5 An embodiment of the present invention provides a mold for the production of motor accessories that is convenient for taking materials, including a workbench 1, a support platform 2 is fixedly installed on the side of the workbench 1, and a template frame is detachably installed on the top of the workbench 1 3. The outer surface of the template frame 3 is provided with a cooling groove 31, and the inside of the cooling groove 31 is detachably installed with a cooling assembly 4, and the side of the workbench 1 is provided with a circular groove 11. The bottom is provided with a movable groove 12, and the inside of the circular groove 11 is equipped with an ejection device 5;

[0023] The cooling assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com