Polytetrafluoroethylene rotary cut plate leveling device

A technology of polytetrafluoroethylene and leveling device, which is applied in the field of leveling device of polytetrafluoroethylene rotary cutting board, which can solve the problems of upturning of the rotary cutting board, decline in the aesthetics of the rotary cutting board, and easy upturning of the rotary cutting board. , to improve the pressing effect, reduce the edge upturning phenomenon, and avoid the effect of slack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

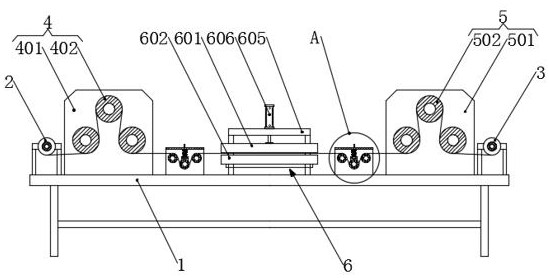

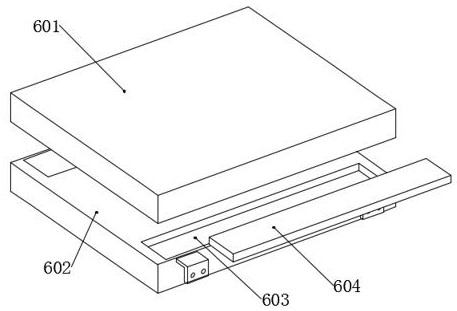

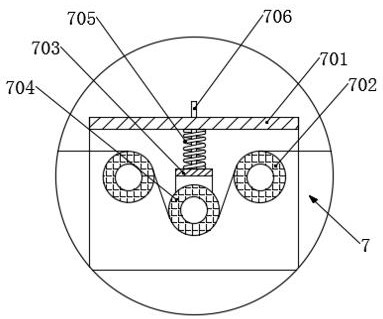

[0024] Example: see figure 1 , a polytetrafluoroethylene rotary cutting plate leveling device, including a processing table 1 and a discharge roller 2 and a winding roller 3 arranged on the left and right sides of the top surface of the processing table 1, the discharge roller 2 is discharged by rotating, The rewinding roller 3 is used to rewind the leveled polytetrafluoroethylene material, and the top surface of the processing table 1 and the position close to the discharge roller 2 are provided with a preheating mechanism 4 for preheating the polytetrafluoroethylene material. The top surface of the processing table 1 and the position close to the winding roller 3 are provided with a cooling mechanism 5 for cooling the polytetrafluoroethylene material, wherein the preheating mechanism 4 includes a first cage fixedly installed on the top surface of the processing table 1 401 and several electric heating rollers 402, the temperature of the electric heating rollers 402 is 150°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com