Molding system and method for substrate glass warping stress partition control

A technology of partition control and warpage stress, which is applied in glass forming, glass forming, glass manufacturing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

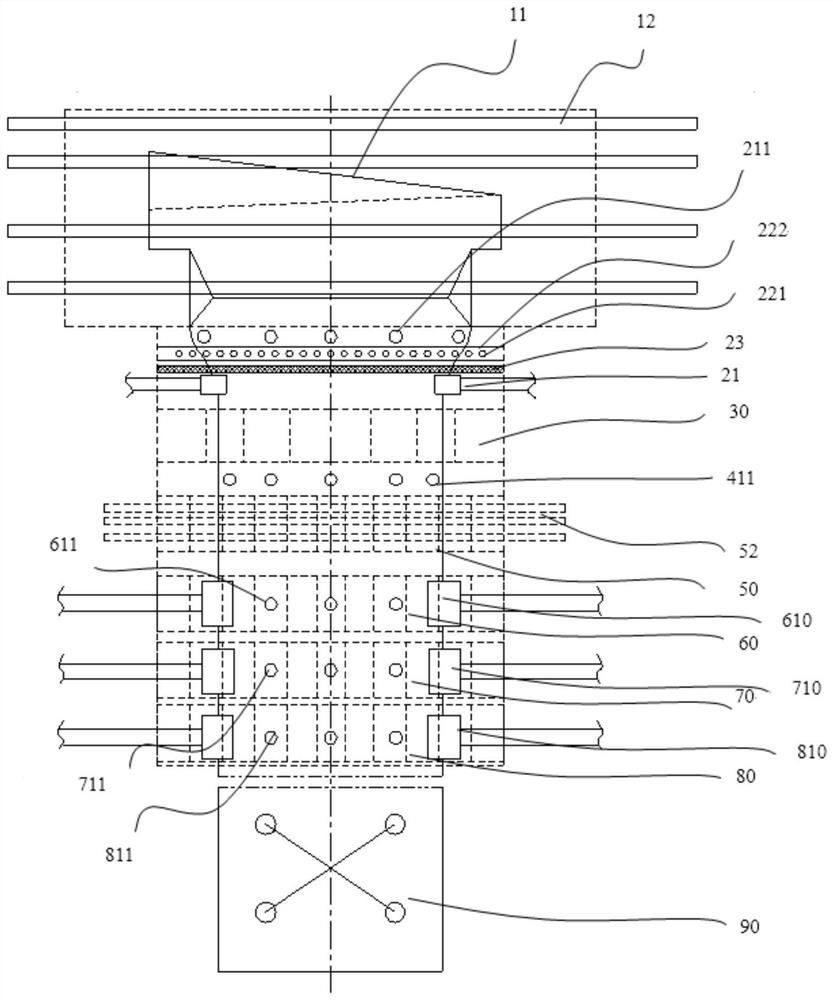

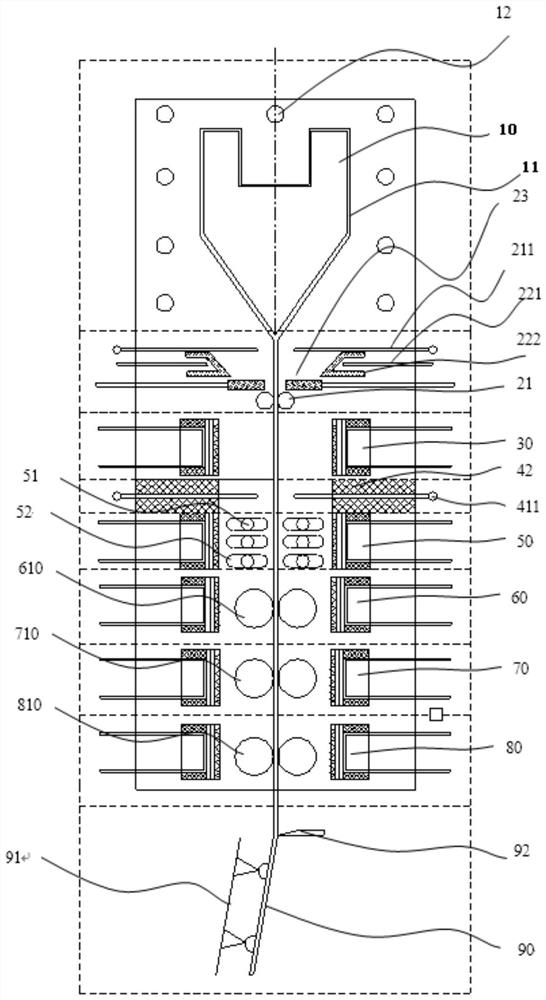

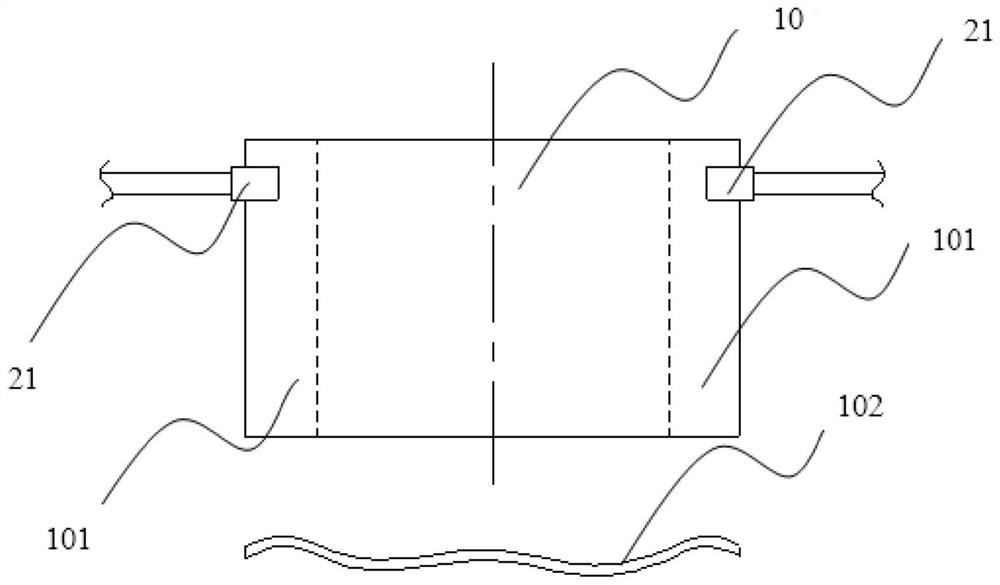

[0046] The present invention relates to a forming system for controlling the warping stress of substrate glass in different zones. The purpose is to finely design the forming equipment according to the viscosity-temperature characteristics of the glass, which are the overflow zone in the first zone, the thickness adjustment zone in the second zone, and the fine temperature adjustment in the third zone. Zone 4, stress buffer relaxation zone, zone 5 rapid cooling forming zone, zone 6 annealing zone, zone 7 cutting zone, to achieve seven refined partition control. like figure 1 As shown, in the overflow area of the first zone of the temperature control system, the viscosity of the molten glass from the feeding system is about 10 3.5 Pa.S, the glass has good fluidity at this time. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com