Light-resistant discoloration modified decorative paper

A decorative paper and light-resistant technology, applied in the field of decorative wallpaper, can solve the problems of wallpaper edge warping, large area of yellowing, gradual yellowing, etc., and achieve the effects of not being easy to warp and curl, reducing moisture content, and reducing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0023] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

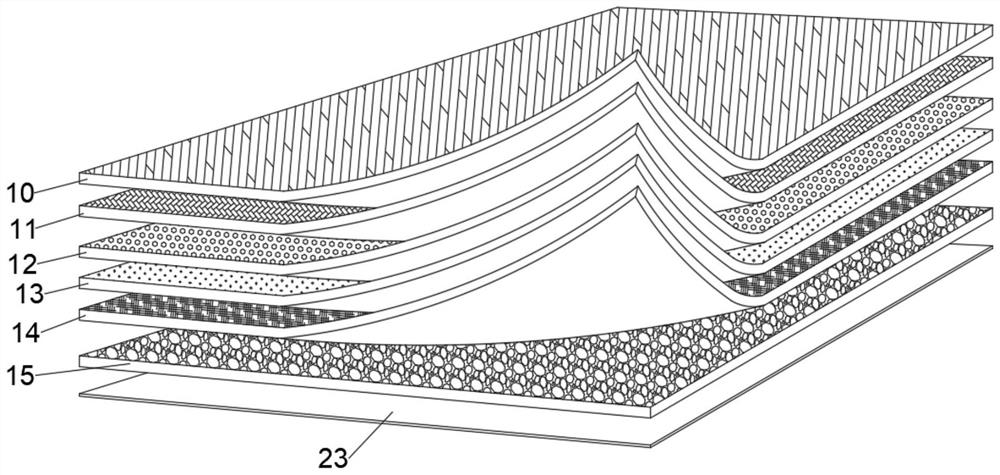

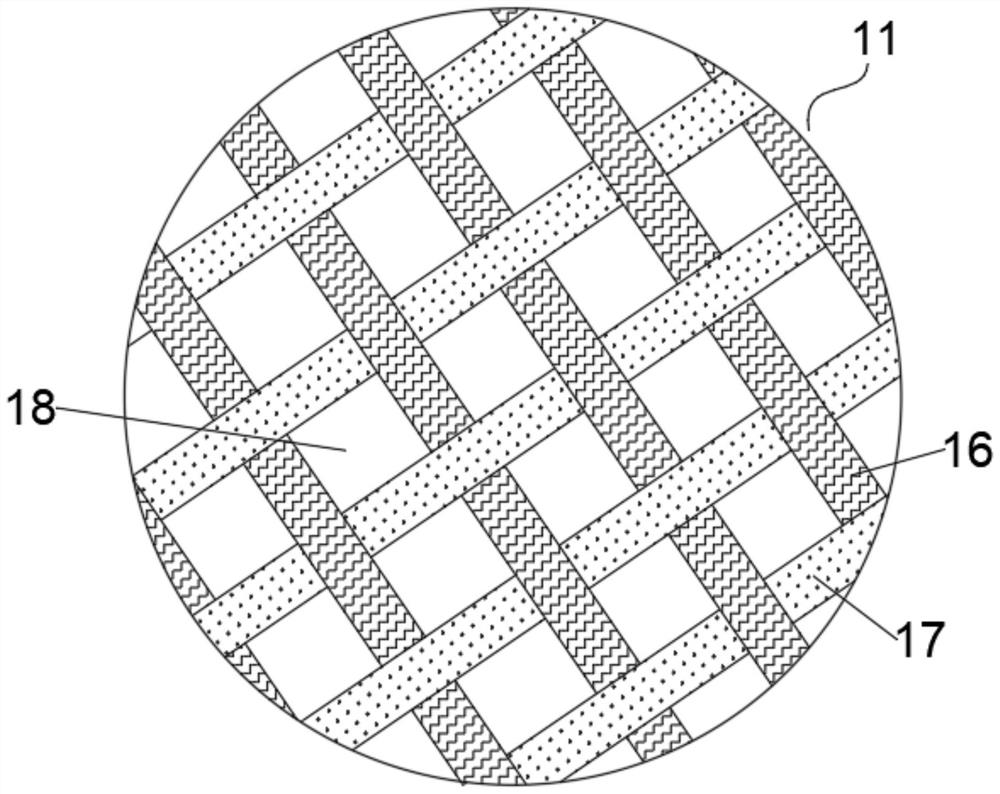

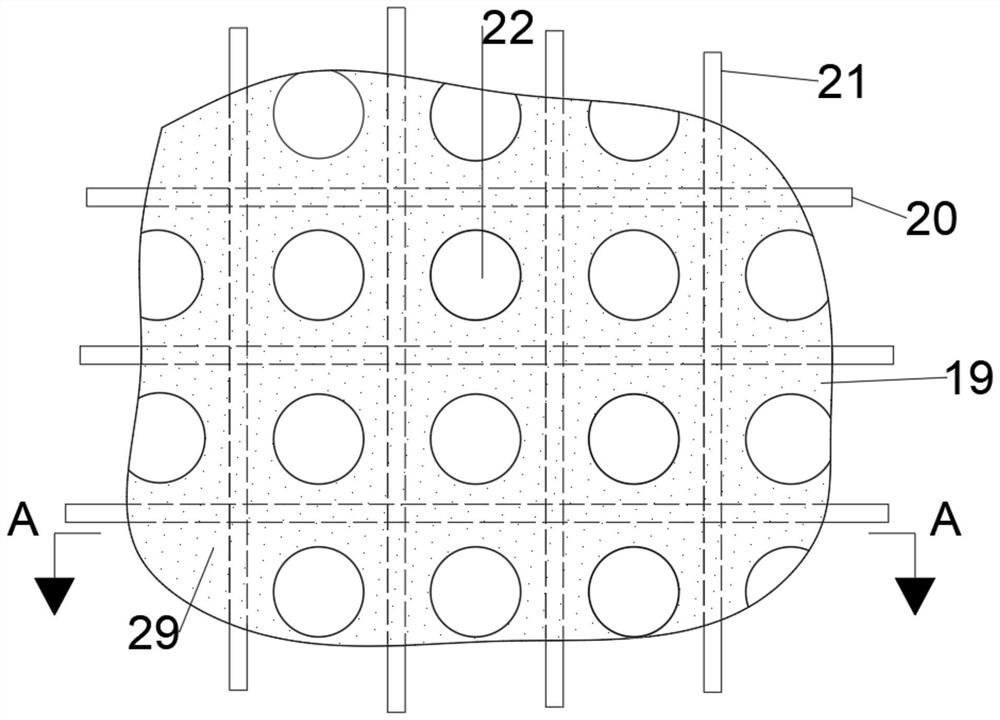

[0024] like Figure 1-5 As shown in the figure, a light-resistant and discolored modified decorative paper according to the present invention includes a reinforced lamination layer 14, a blended fiber layer 12, a pressure-sensitive adhesive 15, and a woven light-resistant layer 11, and the blended fiber layer 12 is arranged on the reinforcement On the upper side of the pressing layer 14, the pressure-sensitive adhesive 15 is adhered to the lower surface of the reinforcing pressing layer 14, and a waterproof release film 23 is at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com