Form-variable wheel type mechanism based on 4D printing technology

A 4D, morphological technology, applied in the directions of manufacturing auxiliary devices, processing heating elements, processing data acquisition/processing, etc., can solve the problems of complex mechanical structure and control system, reduce reliability, restrict development, etc., to simplify complex mechanical structure, The effect of improving reliability and reducing control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in combination with specific embodiments.

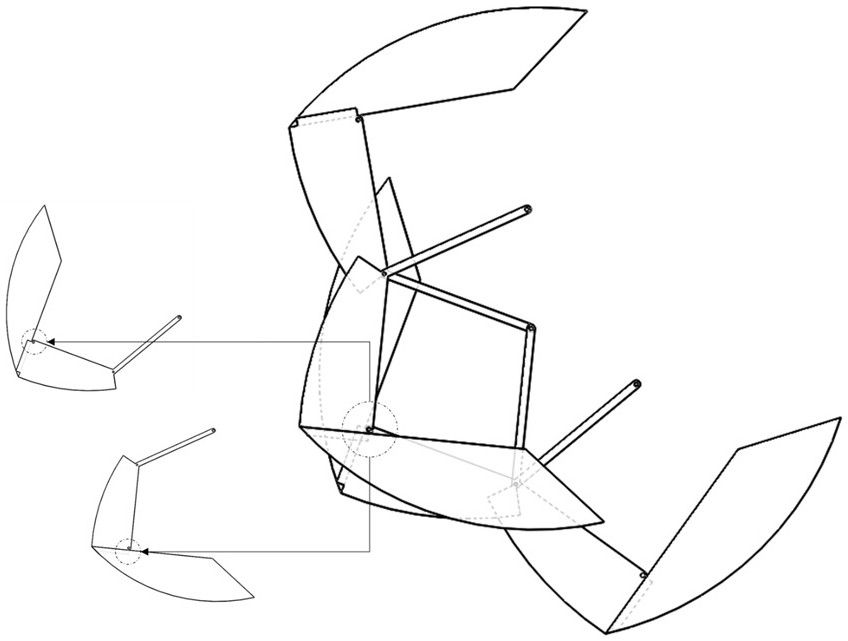

[0021] The invention discloses a shape-variable wheel mechanism based on 4D printing technology, which comprises a non-deformable wheel unit and a deformable 4D printing connecting piece.

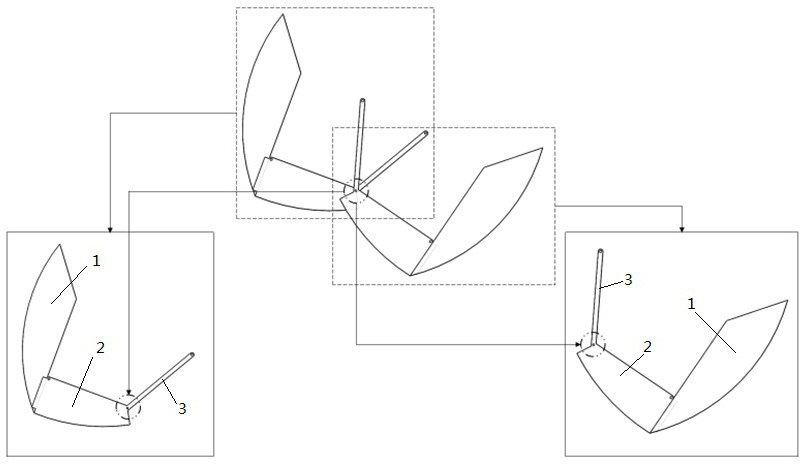

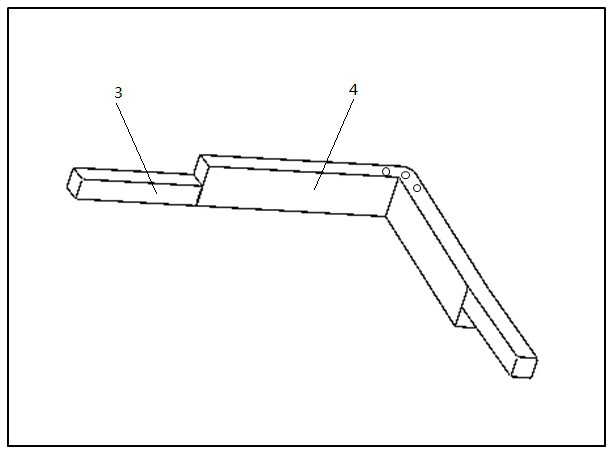

[0022] Such as figure 1 As shown, the non-deformable wheel unit includes a fin-shaped arc-shaped sheet 1 and a trapezoidal-shaped arc-shaped sheet 2 vertically connected to each other through a hinge, and a connecting rod 3 is arranged on the other end angle of the trapezoid-like arc-shaped sheet 2, and the two The two non-deformable wheel units are fixedly connected through the bottom ends of the connecting rods to form a form-controllable angled bar member, and two form-controllable angled bar members are connected to each other through a deformed 4D printing connector 4 connected to the connecting rod 3 .

[0023] Wherein the outer sides of the fin-shaped arc-shaped sheet 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com