Yarn fusing and pressing machine

A technology of melting and pressing, yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

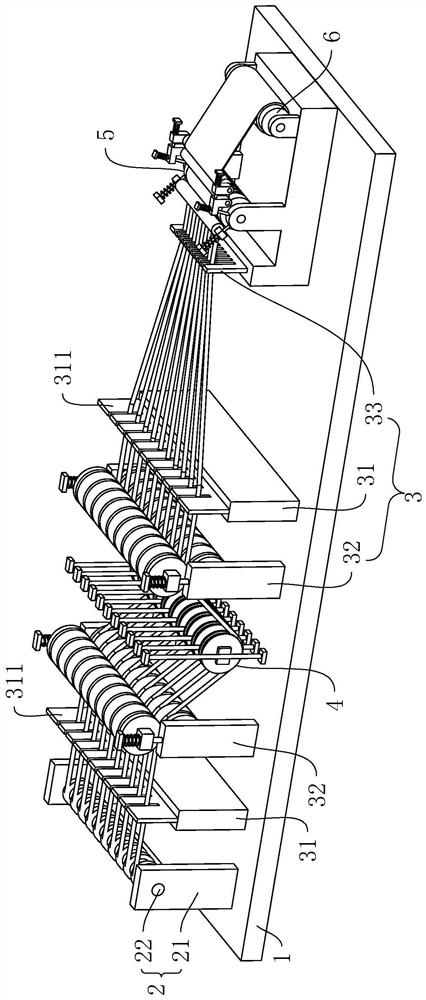

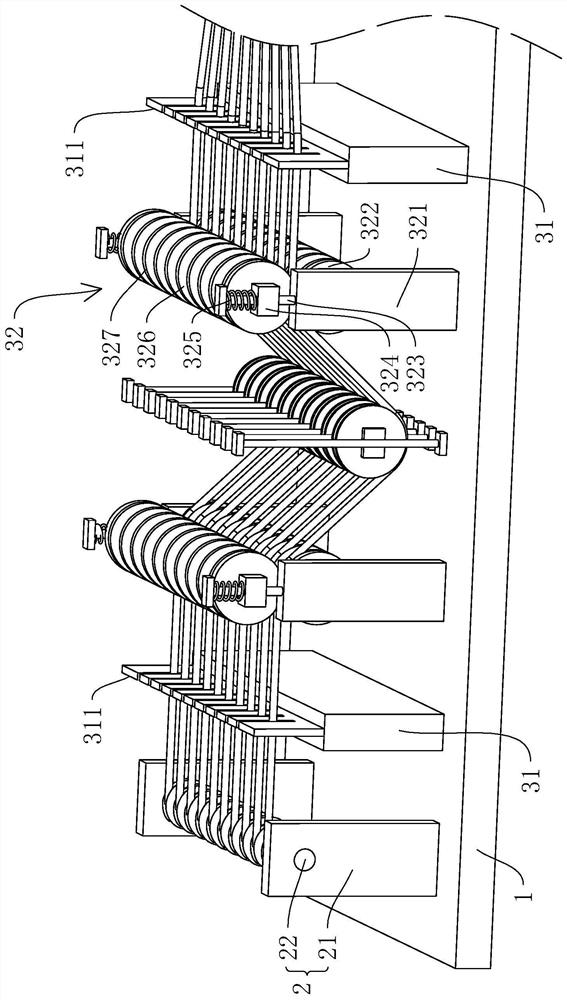

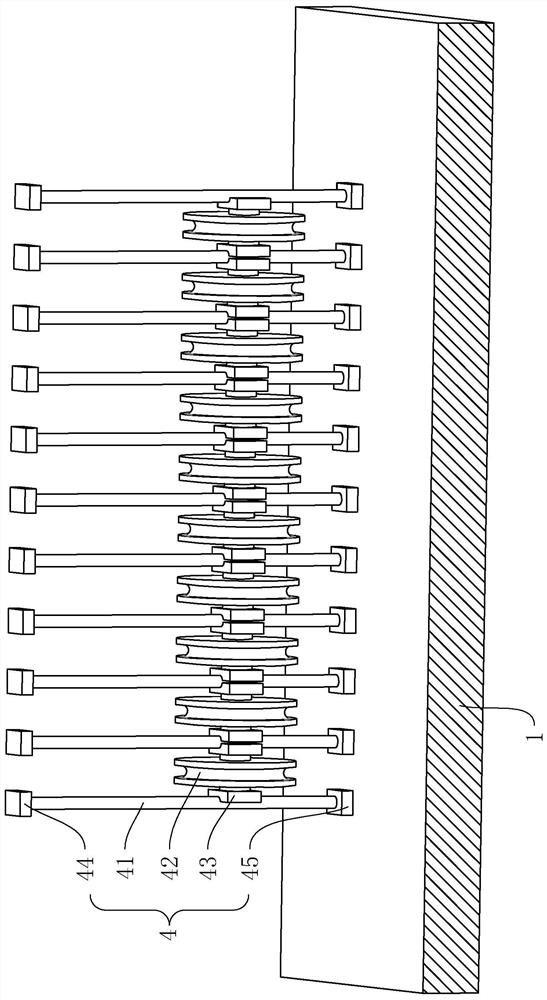

[0043] The following is attached Figure 1-6 The present invention is described in further detail.

[0044] The embodiment of the present application discloses a yarn melting and pressing machine. refer to figure 1, The yarn melting and pressing machine includes a base 1 and a wire supply device 2 , a wire device 3 , a tensioning device 4 , a melting and pressing device 5 and a receiving device 6 arranged on the base 1 in sequence. A plurality of bobbins wound with yarn can be mounted on the yarn supply device 2 at the same time. The thread supply device 2 will release several yarns at the same time, and several yarns move side by side, and then enter the melting and pressing device 5 after passing through the wire device 3 and the tensioning device 4, and the melting and pressing device 5 pairs several yarns The thread enters hot pressing, and the hot-pressed yarn produces transverse deformation, changing from a cylindrical shape to a flat shape, and the edges of two adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com