High toughness transparent resin and preparation method thereof

A technology of transparent resin and high toughness, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carbamic acid derivatives, etc. It can solve the problems of poor toughness and low impact resistance, achieve long service life and improve transparency , high toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation methods of high tough resin, including the following steps:

[0039] S1: According to the weight, 15 weights (2-methyl oxyl oxygen) -ethacetic acid, 28 weights 3-protective amino acid-cycloxane carboxylic acid and 220 weights are protected by nitrogen, under the protection of nitrogen, The reaction is 1.5h at 70 ° C, and the modified 3-protective amino acid-ring hexane carboxylic acid; its structure is:

[0040]

[0041] S2: Modify 24 weights 3-Protective amino acids-cycloxane carboxylic acid, 45 weight tria metharhydramamine and 10 weights of 己 内 s to obtain mixture A;

[0042]S3: Place the mixing A in the reactor, seal, replace nitrogen, discharge the air in the kettle, the nitrogen filling gas to 0.1MPa, raise the temperature to 220 ° C, and react for 3h under the condition of 0.9MPa. It

[0043] S4: The temperature of the mixture B is raised to 200 ° C, and the reaction reacts at 1.1MPa, the reaction is 2H; then the vacuum treatment is pumped, the vacuum t...

Embodiment 2

[0045] Preparation methods of high tough resin, including the following steps:

[0046] S1: According to the weight portion, 20 weights (2-methyl oxyl oxygen) -ethacetic acid, 35 weights 3-protective amino acid-cycloxane carboxylic acid and 300 weight triamine are protected by nitrogen, The reaction is 2h at 60 ° C, and the modification 3-protecting amino acid-cycloxane carboxylic acid;

[0047] S2: Moisturize 35 weights 3-Protective amino acid-cycloxane carboxylic acid, 55 weights of hexyramine and 3 weights of 己 己 s to obtain a mixture A;

[0048] Step S3 and S4 are the same as Example 1.

Embodiment 3

[0050] Preparation methods of high tough resin, including the following steps:

[0051] Step S1 Same Example 2;

[0052] S2: According to the weight, 30 weight modification 3-protective amino acid-cycloxane carboxylic acid, 50 weight triathomylxyl methane dilate and 8 weights are mixed with 己 己 s to obtain a mixture A;

[0053] Step S3 and S4 are the same as Example 2.

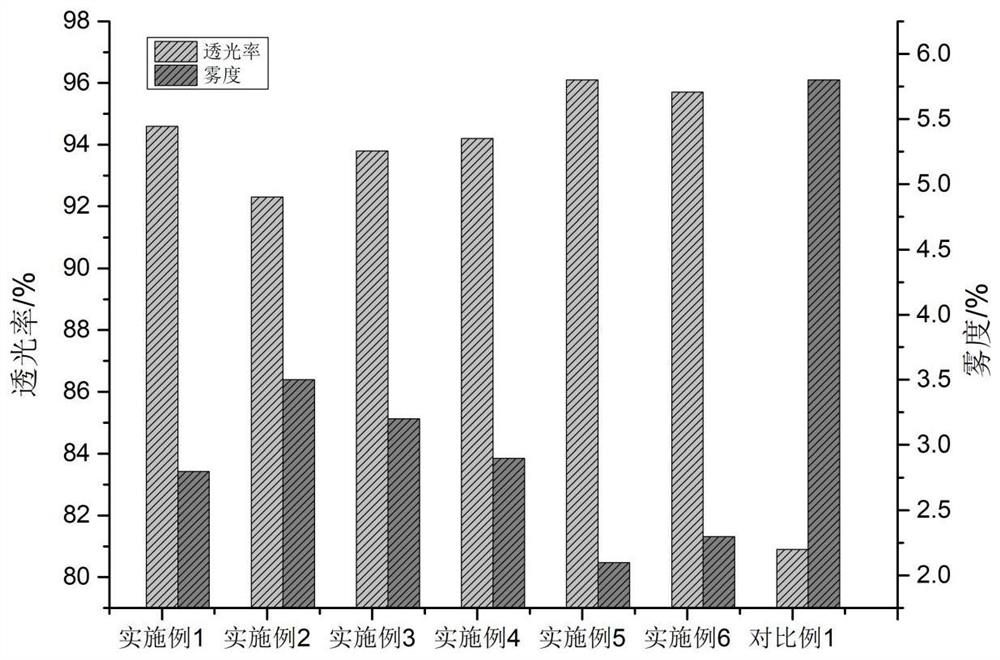

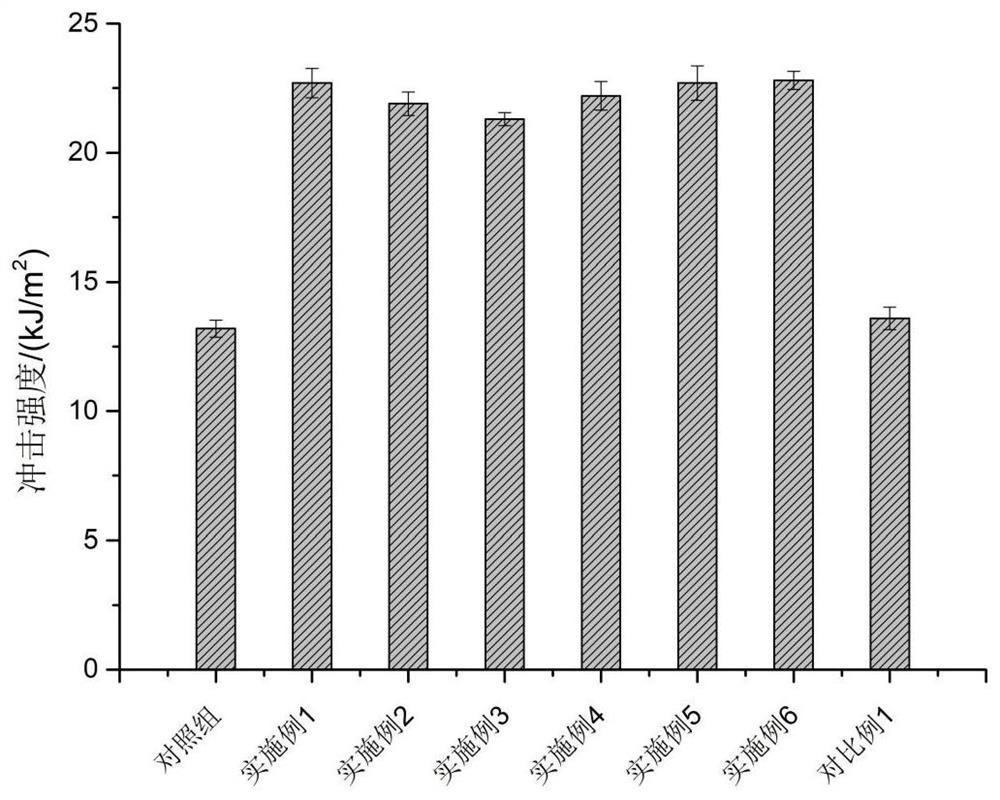

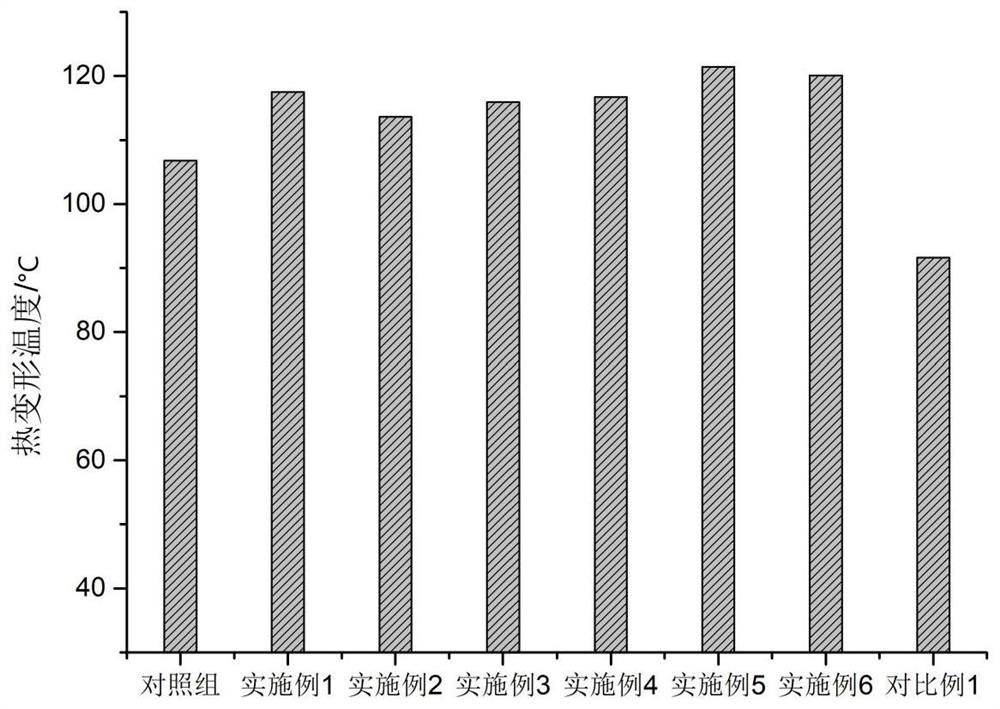

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com