High-precision Mini-LED PCB small bonding pad windowing manufacturing method

A manufacturing method and technology of small pads, which are applied in the fields of printed circuit manufacturing, instruments, electrical components, etc., can solve problems such as shrinking of pads, strict requirements on alignment accuracy and size of solder mask window openings, increase in number and density of pads, etc. , to achieve the effect of high alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

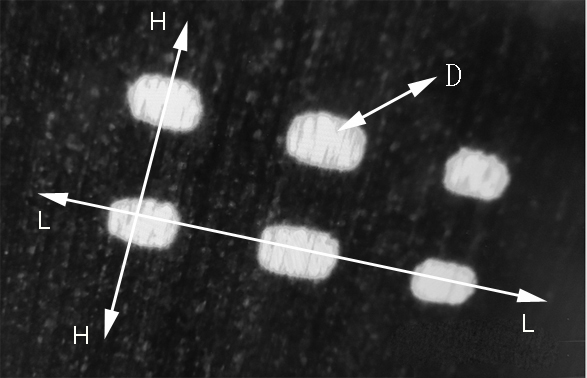

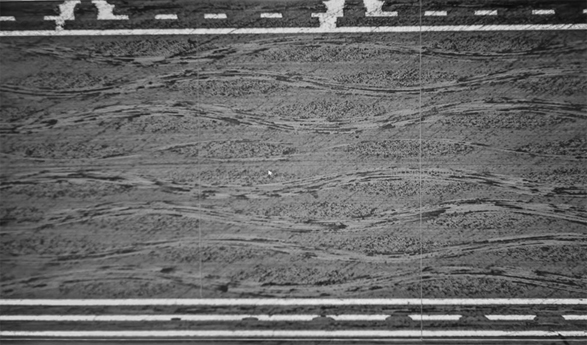

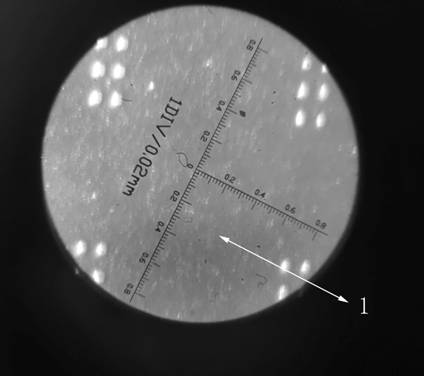

Image

Examples

Embodiment Construction

[0047] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0048] A method for making a small pad window opening of a high-precision Mini-LED PCB is carried out according to the following steps:

[0049] Step 1, the first pretreatment: do not open the needle and grind, open a section of volcanic ash, other parameters are normal, manually place the board, close the board and insert the rack;

[0050] Step 2, the first silk screen printing: use 43T stencil, open oil and water 30ml per kilogram, print on one side, only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com