A transmission type large-aperture infrared lens, processing tooling and processing method

A processing method and large-aperture technology, applied in the field of optical applications, can solve the problems of large-aperture transmissive primary mirror splicing and processing cannot be solved, the spliced primary mirror cannot meet the actual imaging requirements, and the design of the primary mirror frame cannot be too complicated. , to achieve the effect of easy development cycle, reduce the difficulty of splicing, and control the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

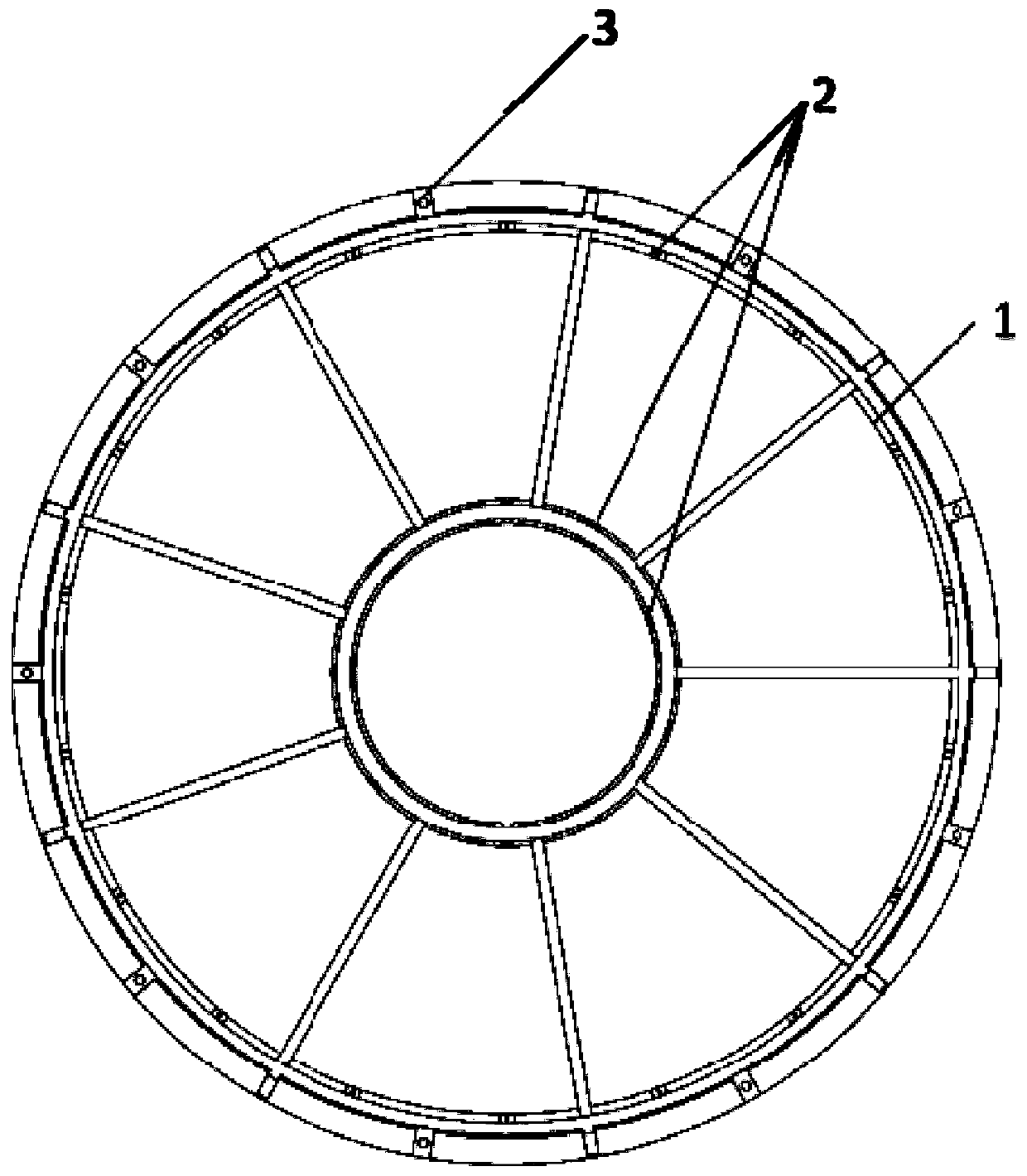

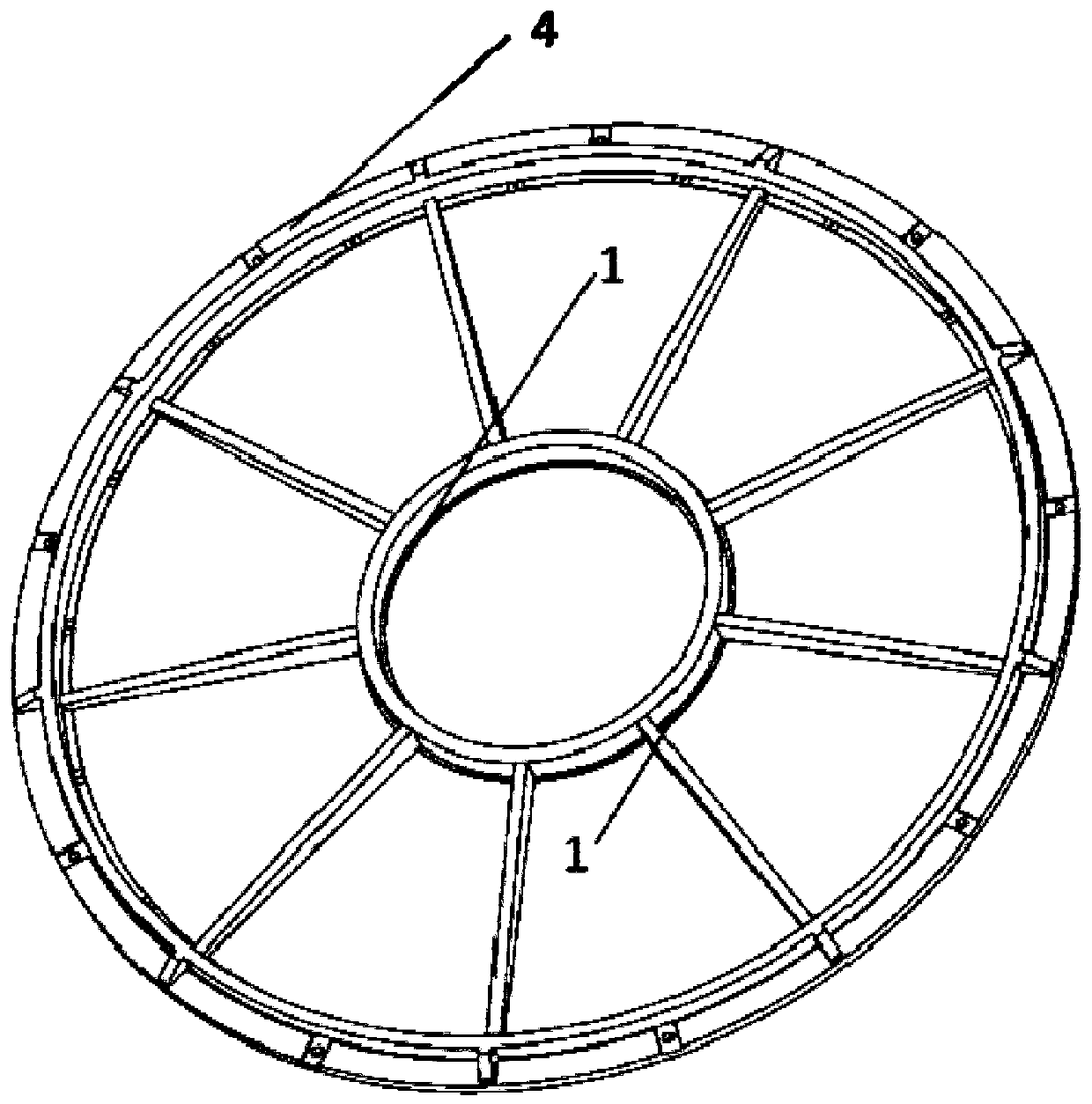

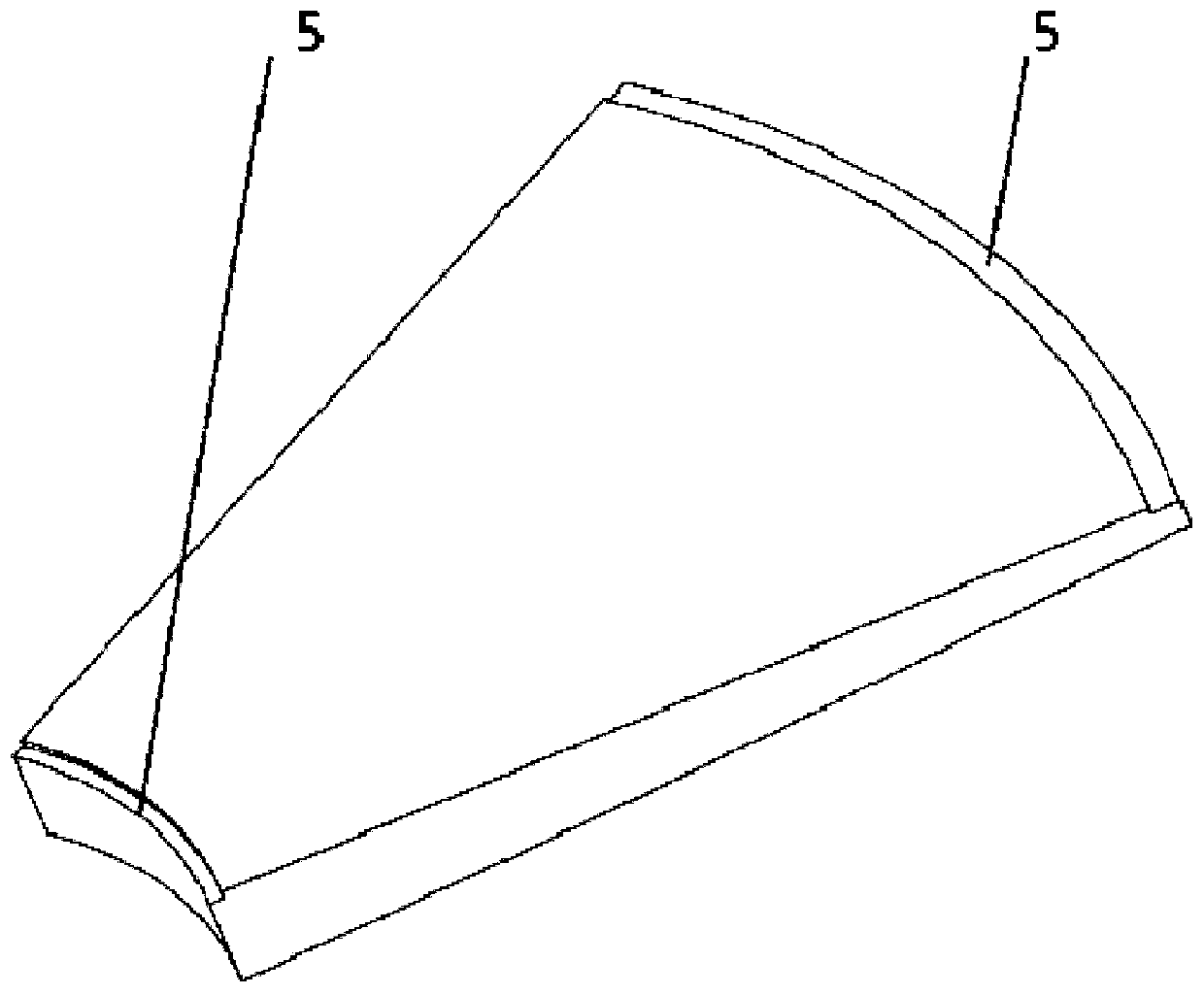

[0048] The present invention changes the splicing at the later stage to the splicing at the early stage. The idea of splicing the main mirror in the past is to process each sub-mirror first, and then splice each sub-mirror together one by one according to the designed splicing form. It is widely used in splicing. However, the splicing of the transmissive primary mirror is different from the splicing of the reflective primary mirror. The splicing of the transmissive primary mirror needs to consider occlusion, so the design of the primary mirror frame should not be too complicated, so the accuracy after splicing directly depends on the processing accuracy, while the optical processing error, The accumulation of structural processing errors and splicing errors often causes the spliced primary mirror to fail to meet the actual imaging requirements. Putting the splicing process before processing has the following advantages: 1. The adjustment mechanism can be omitted, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com