Automatic pineapple picking external hanging device and picking method

A technology for pineapple and pineapple fruit is applied in the field of pineapple automatic picking external devices, which can solve the problems of high equipment cost, low efficiency, reduction and the like, and achieve the effect of simple variant structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

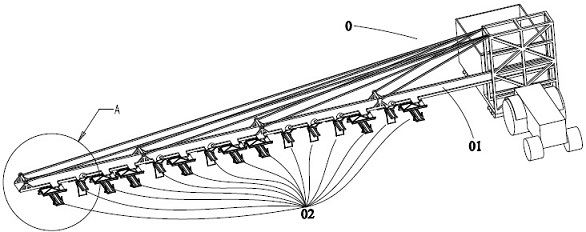

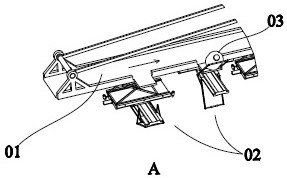

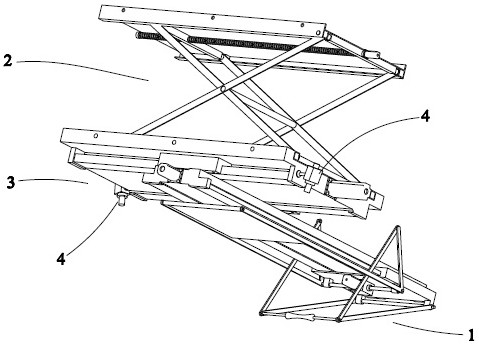

[0037] Such as figure 1 , 2 As shown, the present embodiment provides a pineapple automatic picking external device 02, which is installed on the bottom of the cantilever conveyor belt 01 of the existing large-arm pineapple harvester 0 on the market, and the number of installations can be more than one. Arrange and install according to the number and position of the stations during picking, for example figure 1 Fifteen automatic pineapple picking hanging devices 02 are installed at the bottom of the cantilever conveyor belt 01, figure 2 It is a detailed drawing of the installation of two of the pineapple automatic picking external devices 02 at the bottom of the cantilever conveyor belt 01, namely figure 1 In the partial enlarged view of A in the middle, one of the pineapple automatic picking external devices 02 (right) is ready to put a picked pineapple body 03 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com