Manual and automatic integrated plate bending and shearing machine

An integrated, bending shearing technology, applied in the direction of shearing device, shearing machine equipment, accessories of shearing machine, etc., can solve the problems of troublesome operation and low work efficiency, and achieve the effect of reducing production cost, optimizing resources and streamlining resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

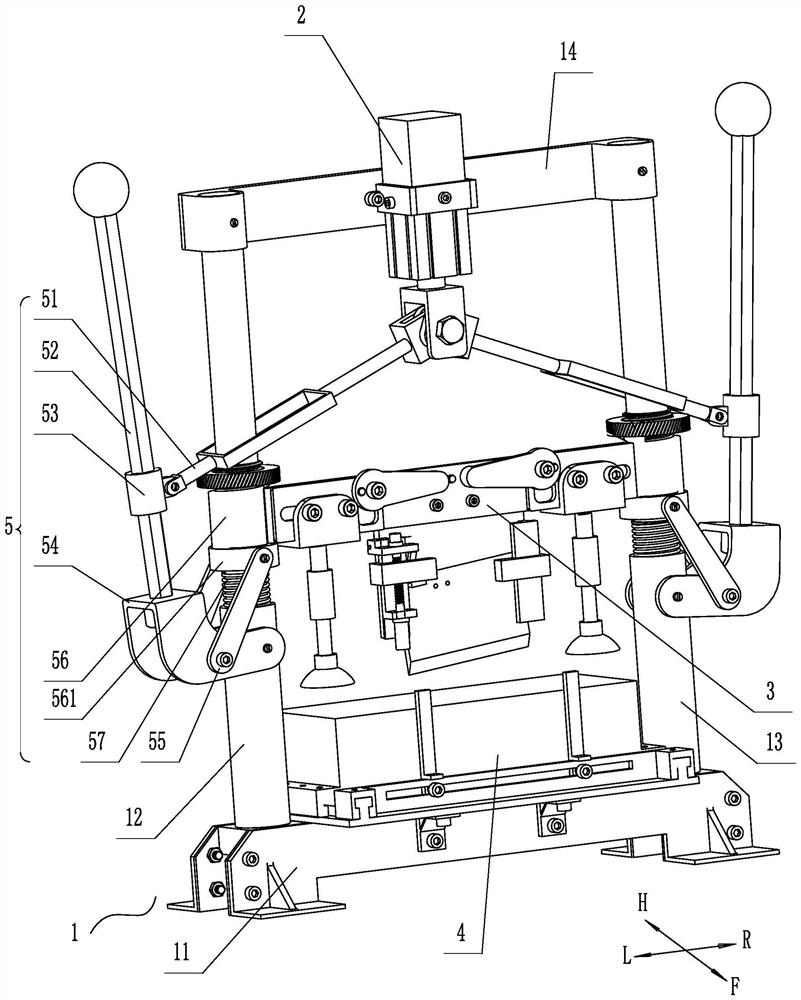

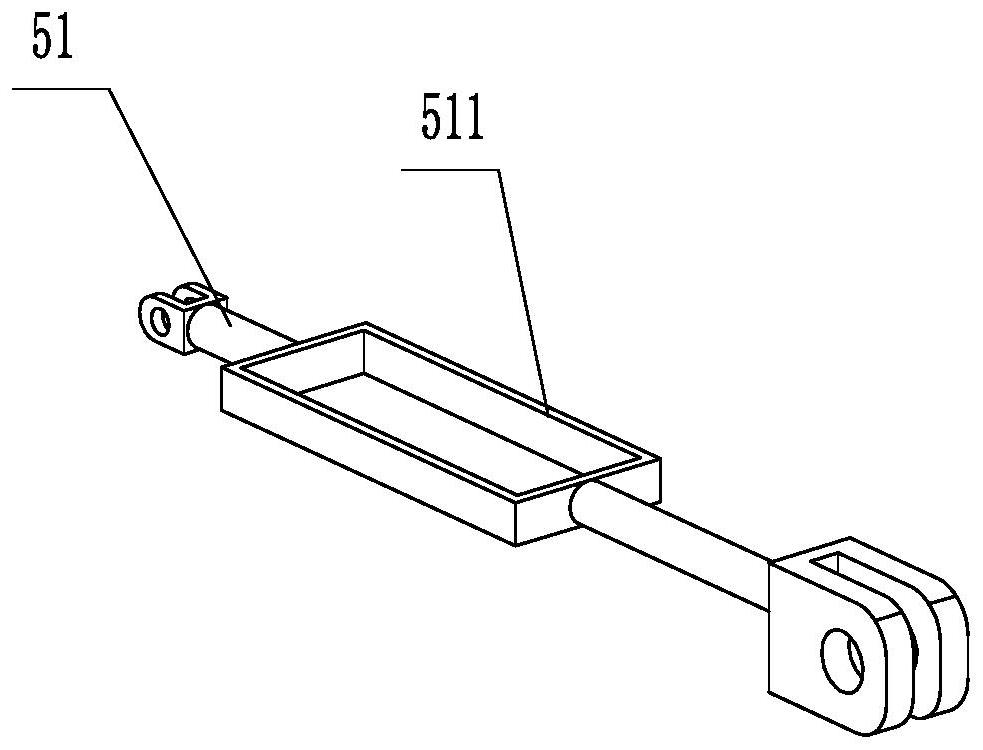

[0085] A manual bending and shearing machine, including a frame 1, a power source device 2, an upper mold assembly 3, a lower mold assembly 4, and a two-stroke transmission linkage mechanism 5, the power source device 2 Installed on the top of the frame 1, the output end of the power source device 2 is connected to the transmission linkage mechanism 5, and the transmission linkage mechanism 5 has two sets, which are symmetrically installed on the left and right ends of the frame 1 respectively. 5 is connected with the upper mold assembly 3, and the lower mold assembly 4 is installed at the bottom of the frame 1, and the upper mold assembly 3 and the lower mold assembly 4 cooperate to realize bending and shearing of the sheet metal. specifically:

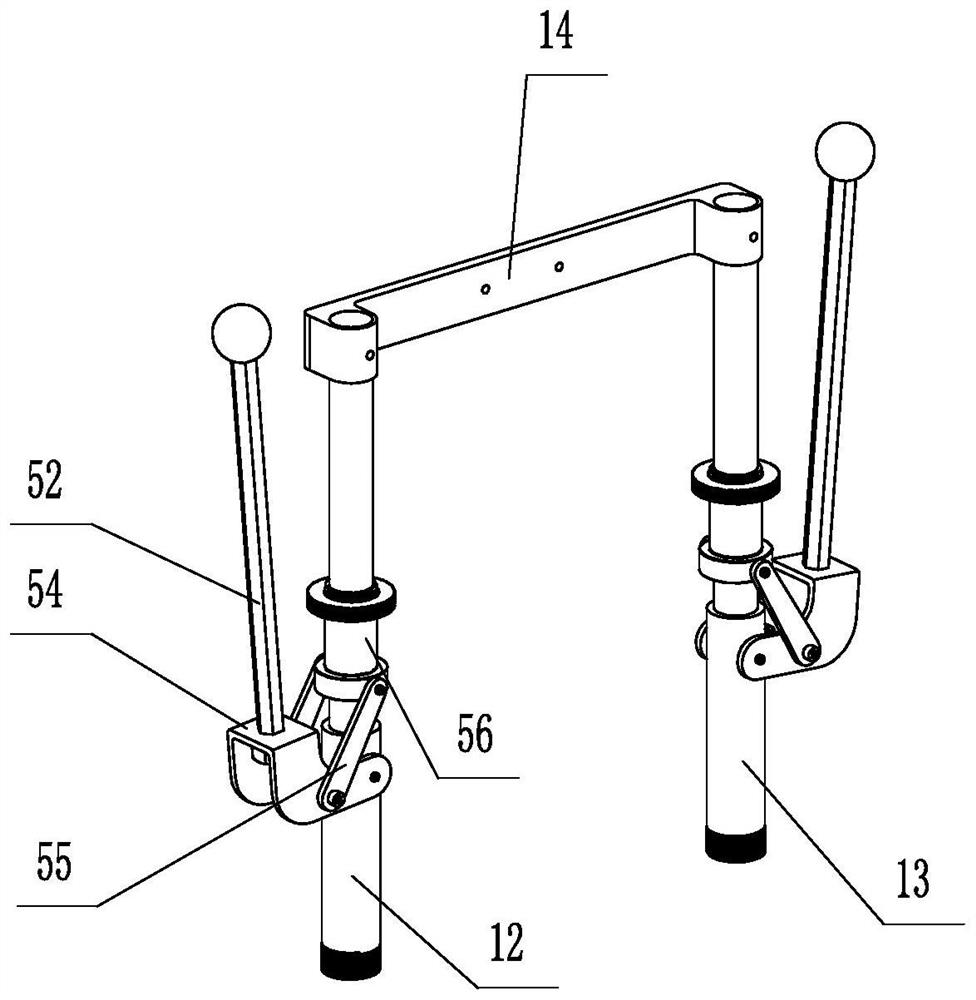

[0086] Described frame 1 comprises base 11, left column 12, right column 13, upper crossbeam 14, and described left column 12, right column 13 all are the stepped columns with small diameter at the upper end and big diameter at the l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap