Bending device for screw gasket

A technology of bending device and screw, which is applied in the direction of feeding device, positioning device, storage device, etc., and can solve the problems of hitting workers' safety hazards, screws and gaskets flying away, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The technical solutions taken by the present invention are as follows:

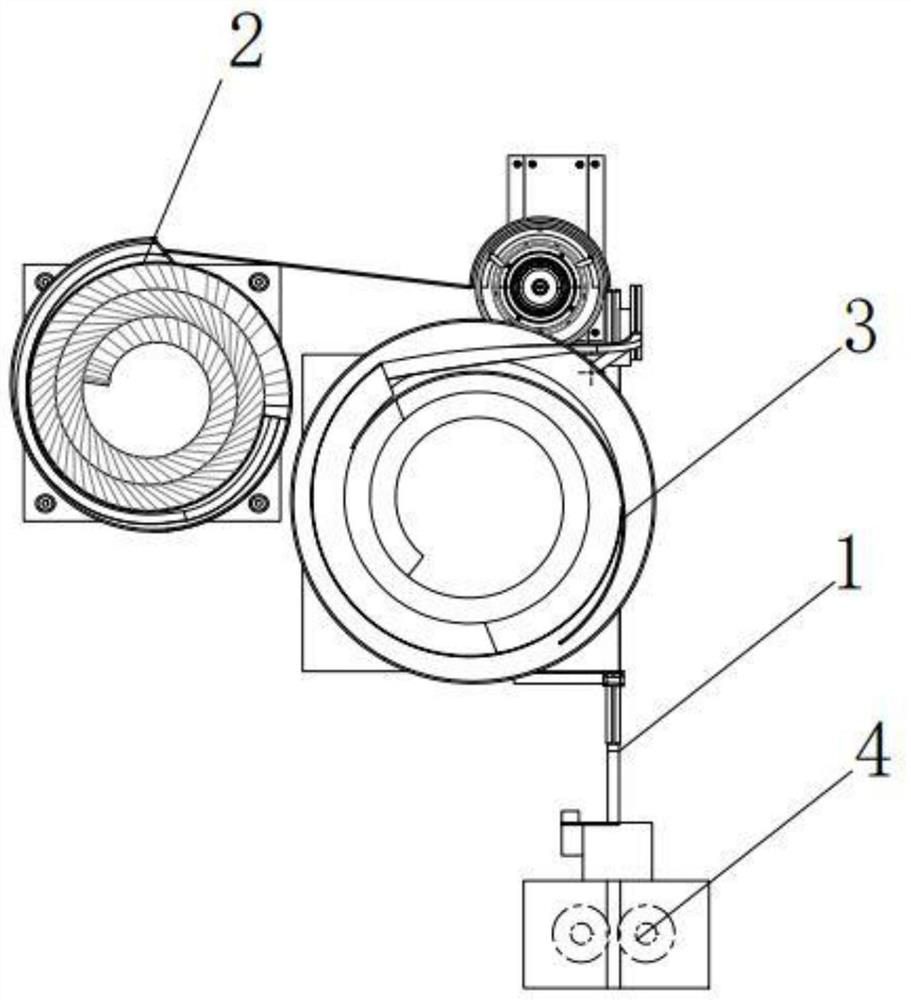

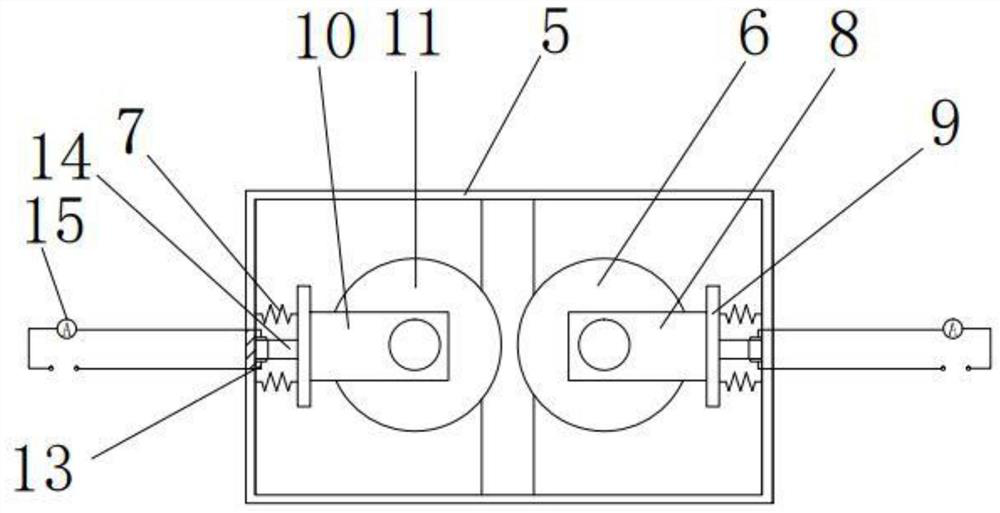

[0038] like figure 1 and figure 2 , The present invention also discloses a gasket screw press bending apparatus, comprising: a transport rail 1, the feed screw oscillating assembly 2, the gasket 3 and the feed screw shim assembly vibration bending assembly 4; the screw vibration feed assembly located at the front end of the conveying path; said vibration feed assembly pad connected to the feed screw located in the rear end of the conveying track assembly vibration; bending the spacer screw assembly connected to the end of the conveying path; wherein said screw press brake pad assembly includes a cartridge 5, the cartridge body 6 is provided with a pair of squeezing structure, the pair of side walls respectively connecting extruded structure of a first spring cassette 7; the extruded structure comprises a holder 8 said holder comprising a bottom plate 9 and a pair of side plates connecting the bottom pl...

Embodiment 2

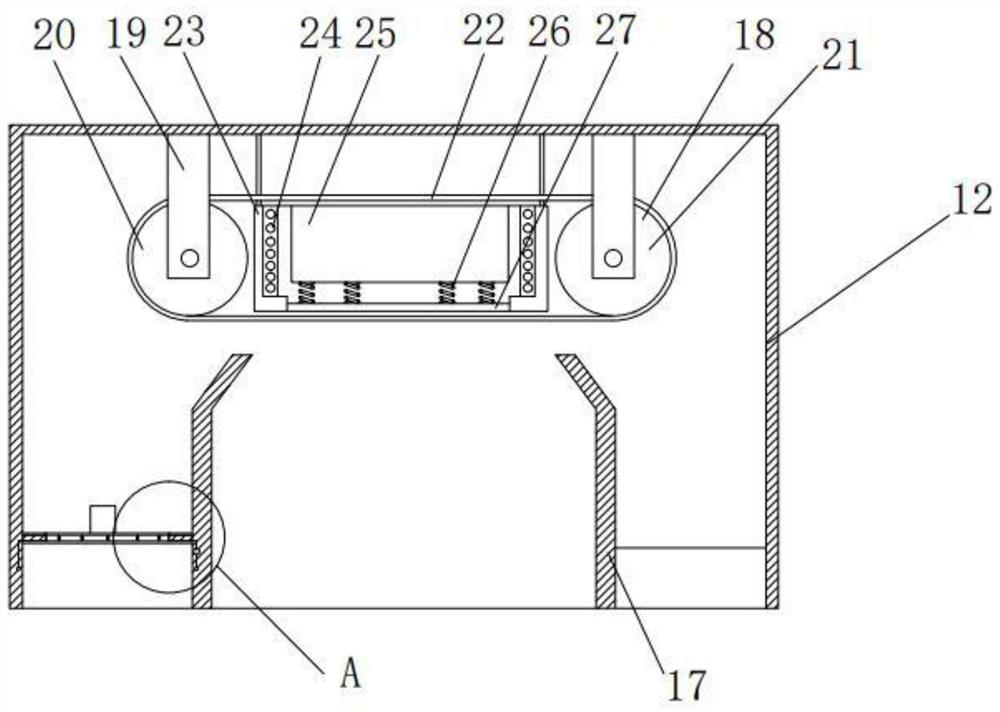

[0041] like image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 , The present invention also discloses a gasket screw press bending apparatus, comprising: a transport rail, the feed screw vibration assembly, the gasket assembly and the feed screw washer bending vibration assembly; said vibration feed screw assembly at the front end of the conveying path; said vibration feed assembly pad connected to the feed screw located in the rear end of the conveying track assembly vibration; bending the spacer screw assembly connected to the end of the conveying path; wherein the spacer screw press bending assembly includes a cartridge body, the cartridge body is provided with a pair of squeezing structure, a pair of side walls connected by extruded structure are cartridge spring; said extruded structure comprises a holder, said holder comprising a base plate and a connection plate a pair of side plates, the wheel is mounted between the pair of side plates; top of the box body is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com