New energy vehicle battery spring processing production line

A new energy vehicle and production line technology, applied to wire processing, battery pack parts, springs made from wires, etc., can solve problems such as low production efficiency and increased processes, and achieve the effect of saving efficiency and cost and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

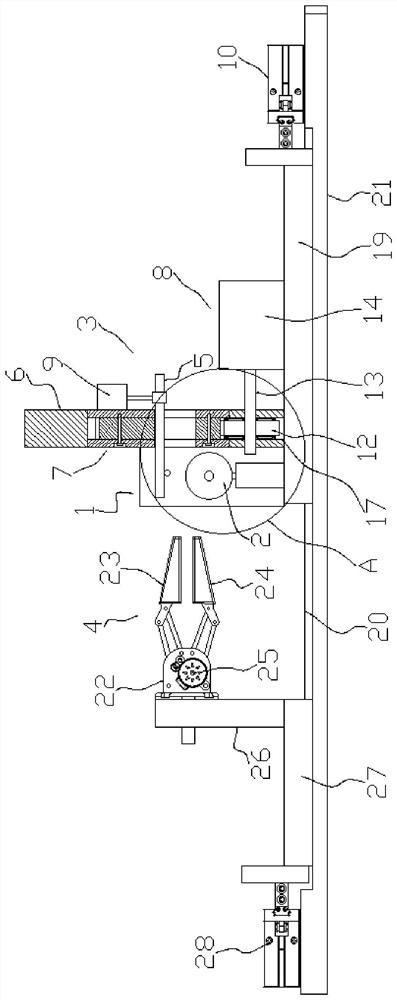

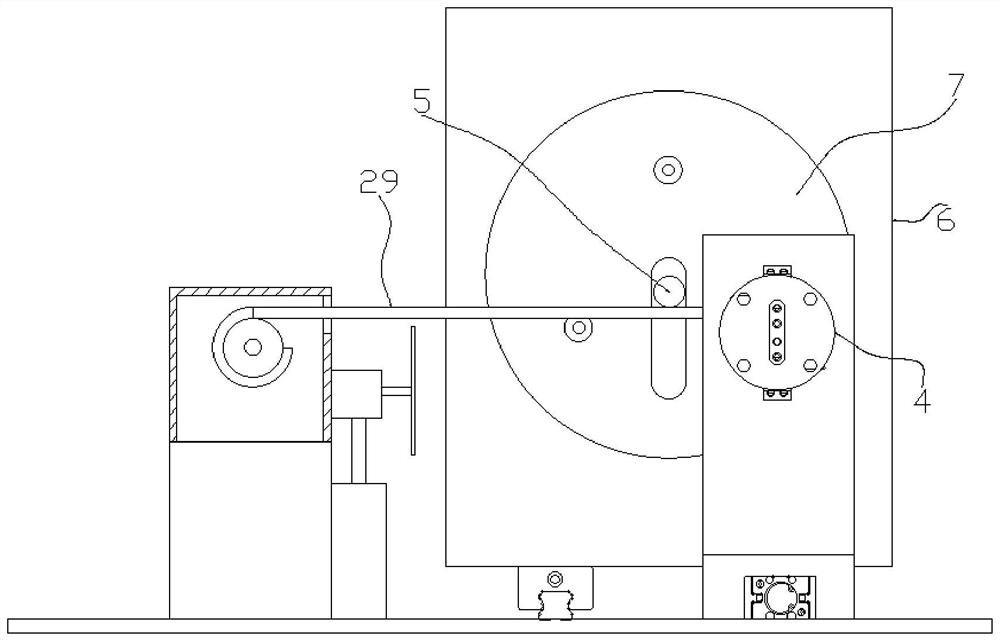

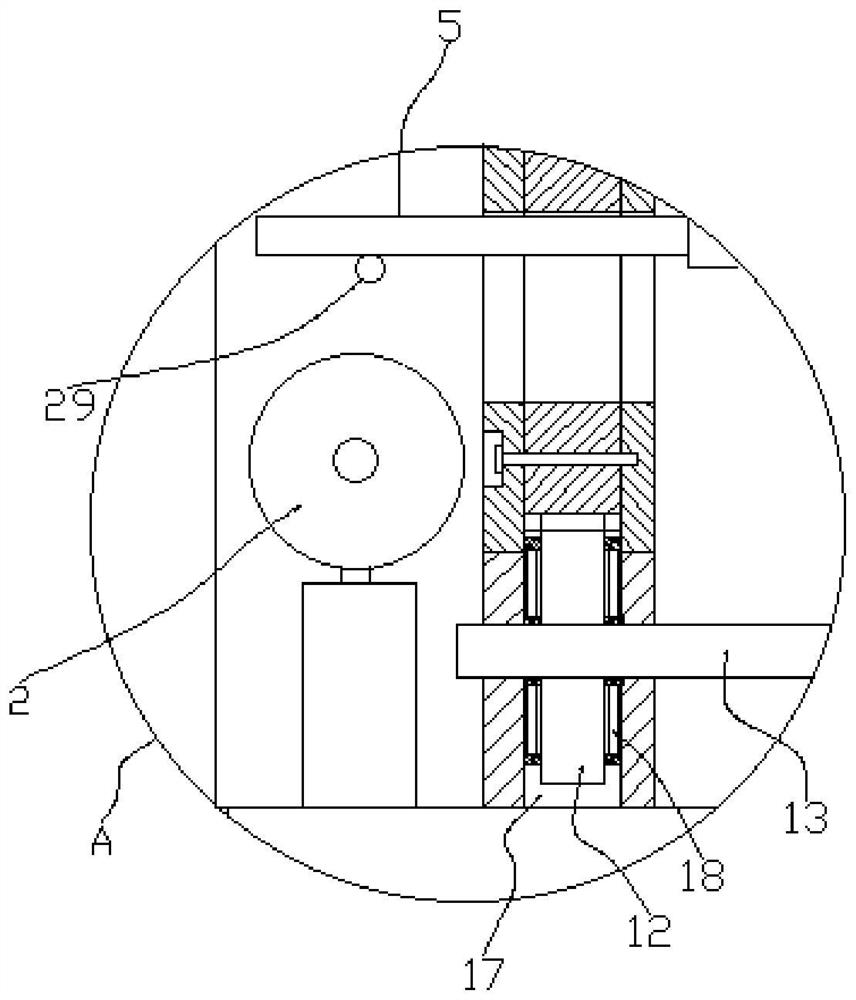

[0023] Such as Figure 1~2 As shown, a new energy vehicle battery spring processing production line of the present invention includes a conveying device 1 for conveying spring wire 29, a cutting device 2, a winding device 3 and a clamping device 4 arranged in sequence along the conveying direction of the conveying device 1 , the conveying device 1 includes a wire reel for winding the spring wire 29 , and the wire reel can use the prior art to actively or passively convey the spring wire 29 .

[0024] In this embodiment, the clamping device 4 is used to clamp the outer end of the spring wire 29, which is more beneficial to the winding of the spring wire 29. The winding device 3 is used to wind the spring wire 29, and the clamping device 4 After being clamped again, it can be rotated together with the spring wire 29, so that the winding process can be carried out smoothly. The cutting device 2 is used to cut the spring wire 29. The cutting knife adopts the prior art, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com