Anchorage device sectioning device, sectioning device and sectioning method thereof

A kind of anchorage, a pair of technology, applied in the field of cutting technology, can solve the problems of cumbersome operation process, laborious manual lifting, low work efficiency, etc., and achieve the effect of saving manpower, avoiding injury and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

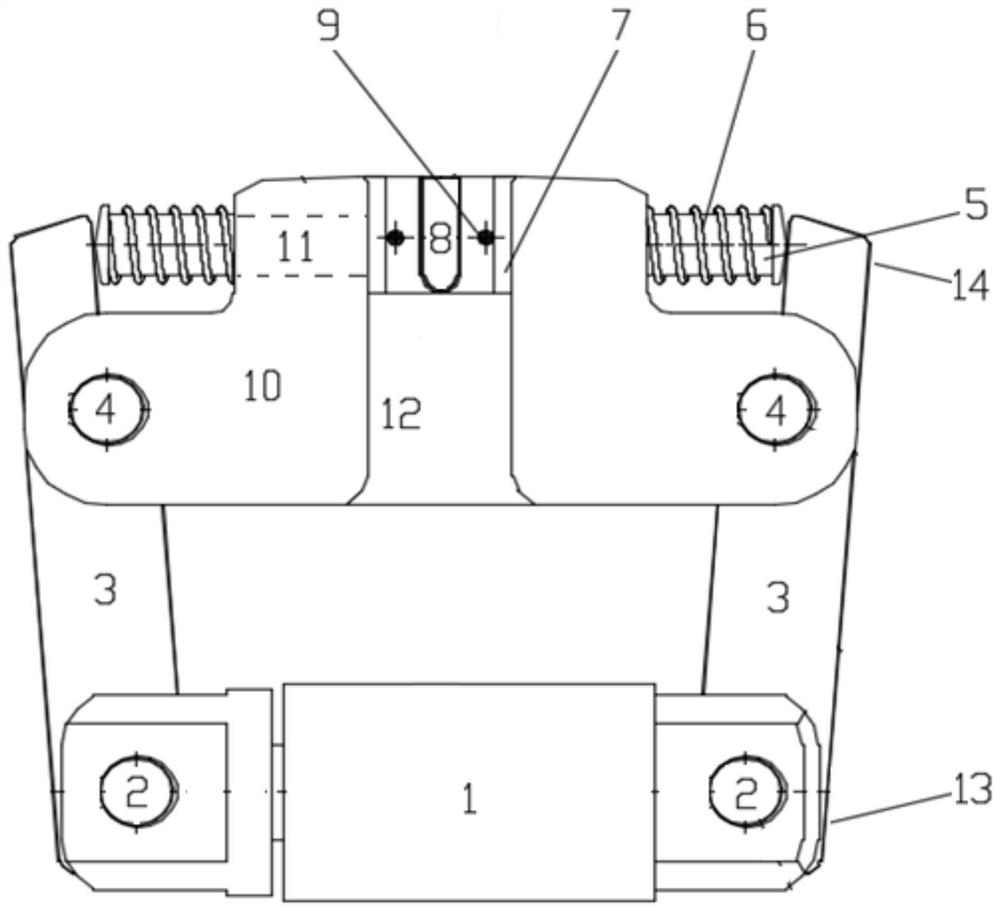

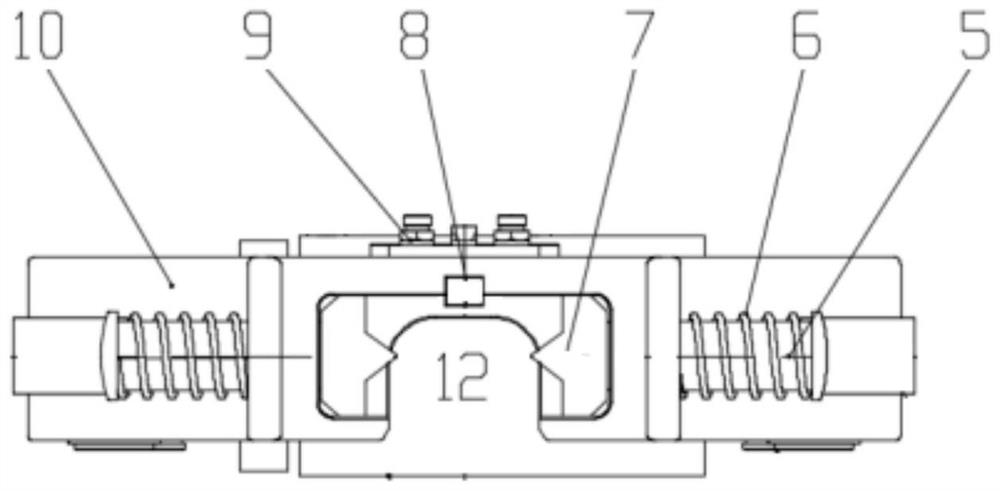

[0019] Looking down at the anchorage cutter, the structure is as follows figure 2 As shown, an opening 12 is provided in the middle of the body 10, and the opening 12 is facing the cutting surface, and a pair of nozzles 9 are arranged inside, installed on the inner wall of the body 10, facing the cutting surface, and a knife setting block 8 is arranged between the nozzles 9, and a knife setting block 8 Installed on the inner wall of the machine body 10, it can be replaced according to the shape of the anchor, and resists the anchor.

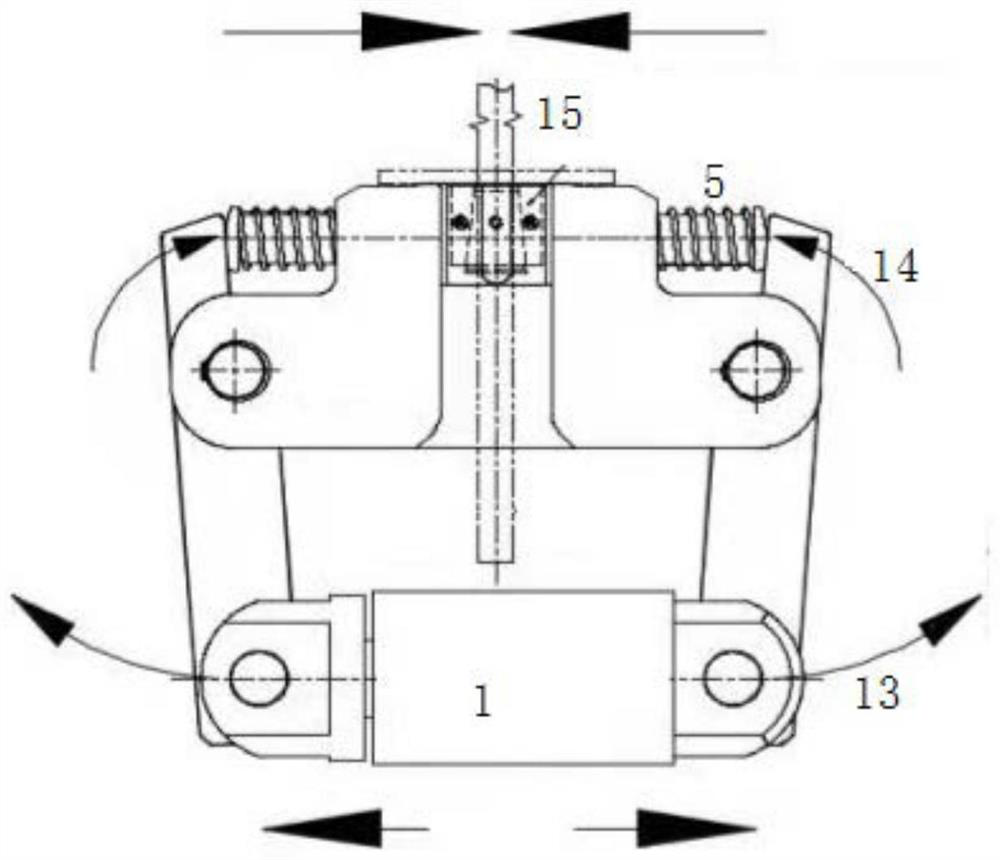

[0020] View the anchorage cutter from the cutting plane, such as figure 1 As shown, the two ends of the body 10 are connected to the lever 3 through the fulcrum pin 4, the two ends of the two-way oil cylinder 1 are connected to the cylinder end 14 through the hinge pin 2, and a pair of slideways 11 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com