High-density shuttle vehicle storage system and storage method

A technology of storage system and shuttle car, which is applied in high-density shuttle car storage system and storage field, can solve the problems of complex installation and commissioning of conveyor lines, difficulties in installation and commissioning of conveyor lines, and bottlenecks in warehouse entry and exit efficiency, and achieve flexible path planning, The effect of avoiding congestion at the exit of the warehouse and reducing the risk of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

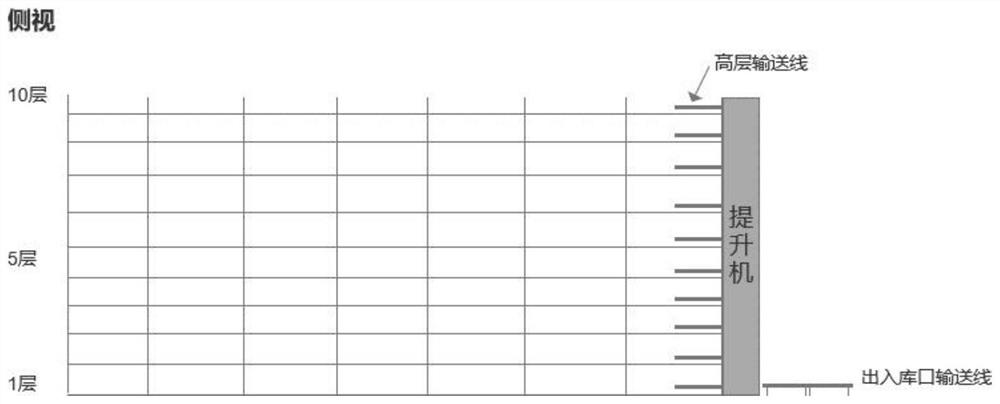

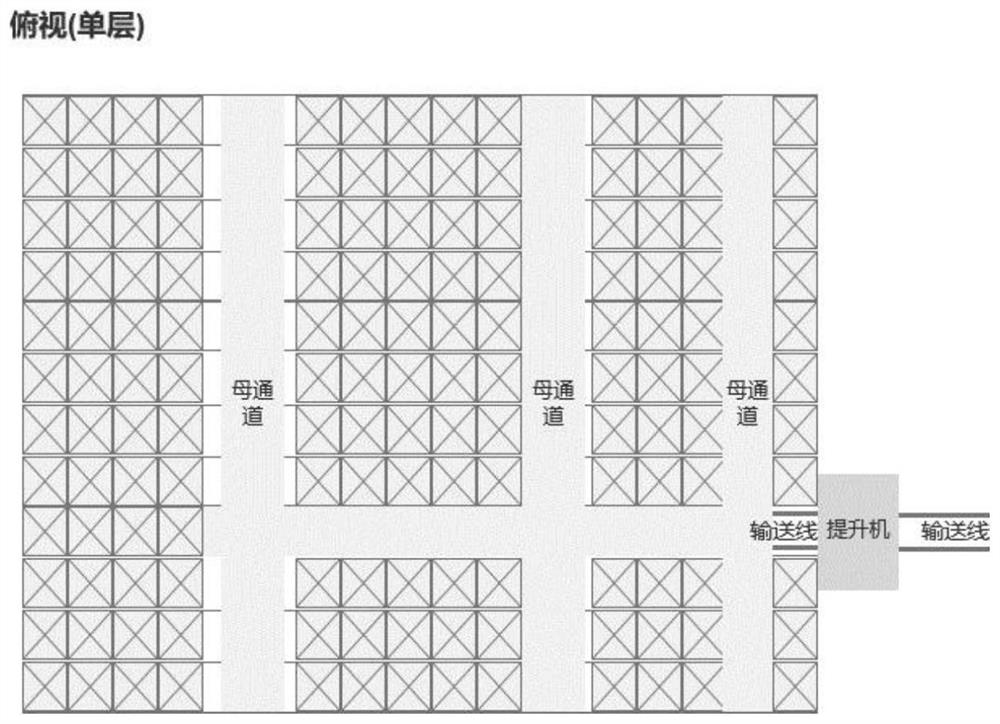

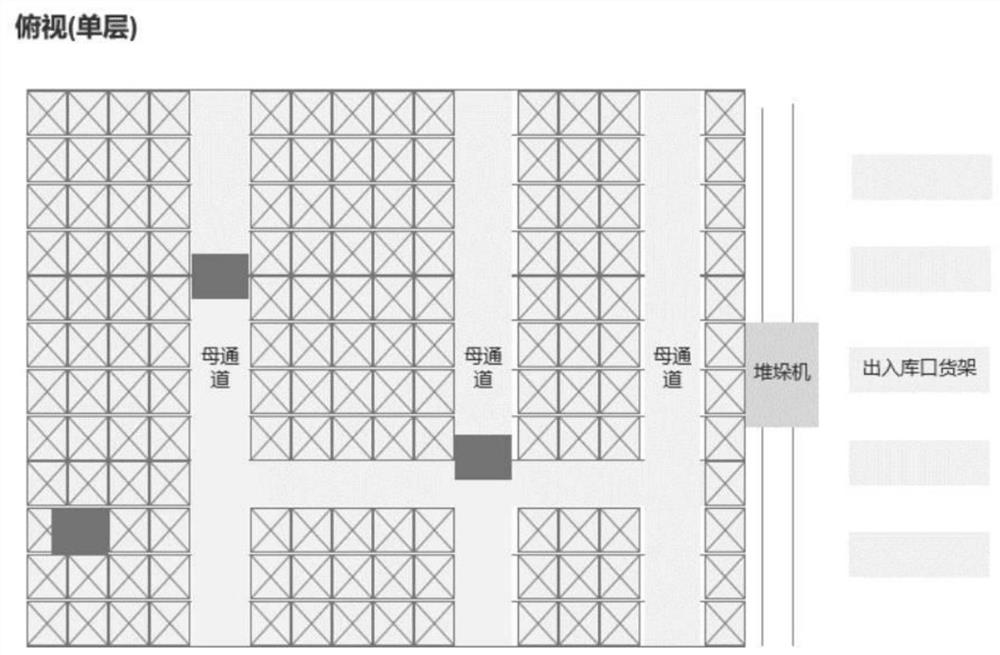

[0029] This Example describes the shuttle a high density storage system, comprising:

[0030] Shuttle car shelves, four-way shuttle, stackers, track and out of storage shelves mouth;

[0031] The shuttle shelf grid-like structure, and a plurality of interior cargo space, the four-way shuttle is provided with a plurality of back and forth movement of the shuttle on the shelf, particularly for transporting cargo to the cargo and remove;

[0032] The stacker and a track provided on a side of the shuttle vehicle shelf, a stacker provided on the slide rails, and the elevating structure is a stacker, the opening out of storage shelves provided side stacker.

[0033] Close to the surface of the outer sides of the cargo space shuttle shelves are arranged stacker and the rail; the rail and the side of the shuttle car shelves parallel to each other; said outlet out of storage shelves is provided with a plurality of parallel, It is provided in the sliding direction of the stacker machine; co...

Embodiment 2

[0035] This embodiment describes a method of storing the shuttle vehicle according to a high density storage system of embodiment 1, comprising:

[0036] When carrying out the one or more libraries of goods, the shuttle by one or more four-way simultaneous delivery of the goods on the shelf locations positive cargo stackers, the stacker by sequentially slid to the track, through the stack fork on the machine pick;

[0037] When the storage, a plurality of parallel goods truck placed on a shelf storage port, by moving on the rail stackers, in turn, to cargo handling any cargo space adjacent thereto, through the four-way shuttle pickup library.

[0038] High density provided in this embodiment a shuttle car storage method of the storage system, the application process is particularly directed to the following steps:

[0039] First, when the library materials

[0040] Upstream server can follow the principle of the optimal path, the four-way vehicle dispatch goods placed anywhere pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com