Automobile bulk grain side unloading machine

A technology for vehicles and grain tanks, applied in loading/unloading, solid separation, filtering and sieving, etc. It can solve the problems of adjusting the inclination angle of the scraper, damage, and affecting the efficiency of unloading grain and grain quality, so as to protect the scraper and avoid rigid impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

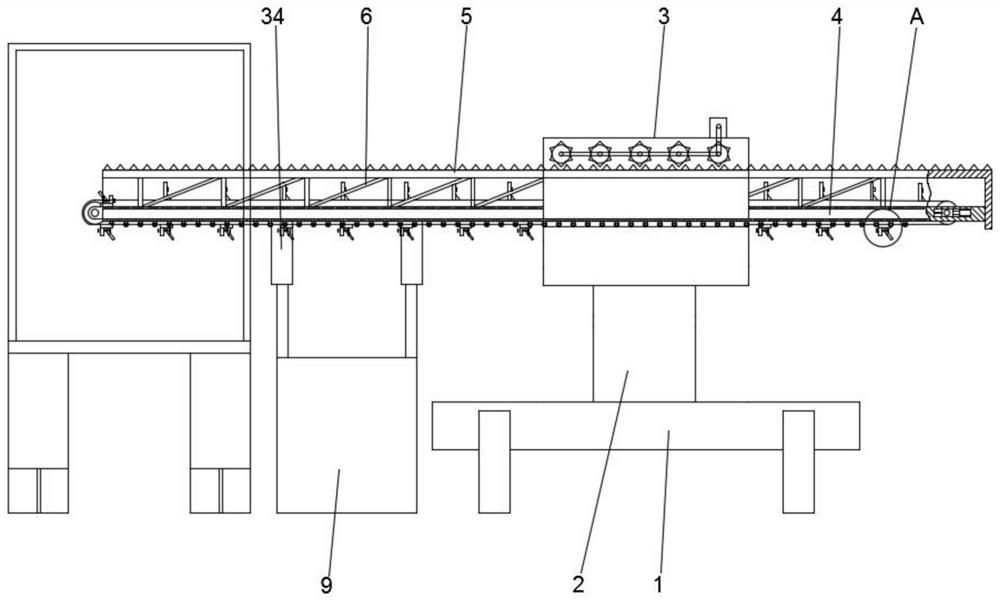

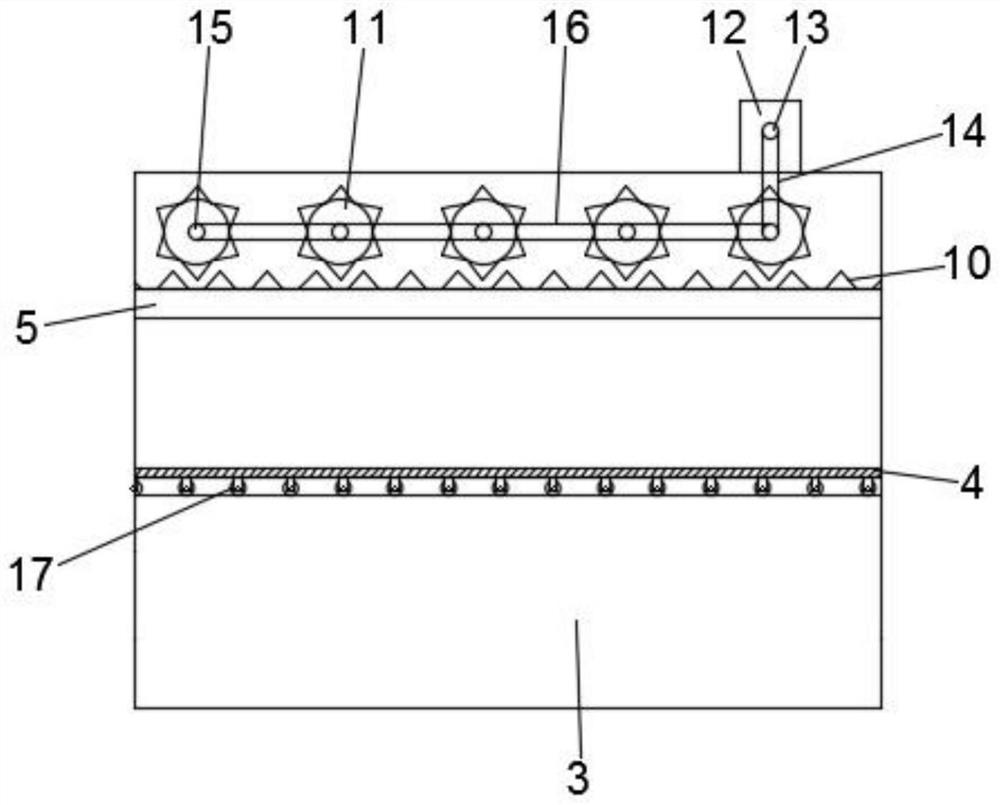

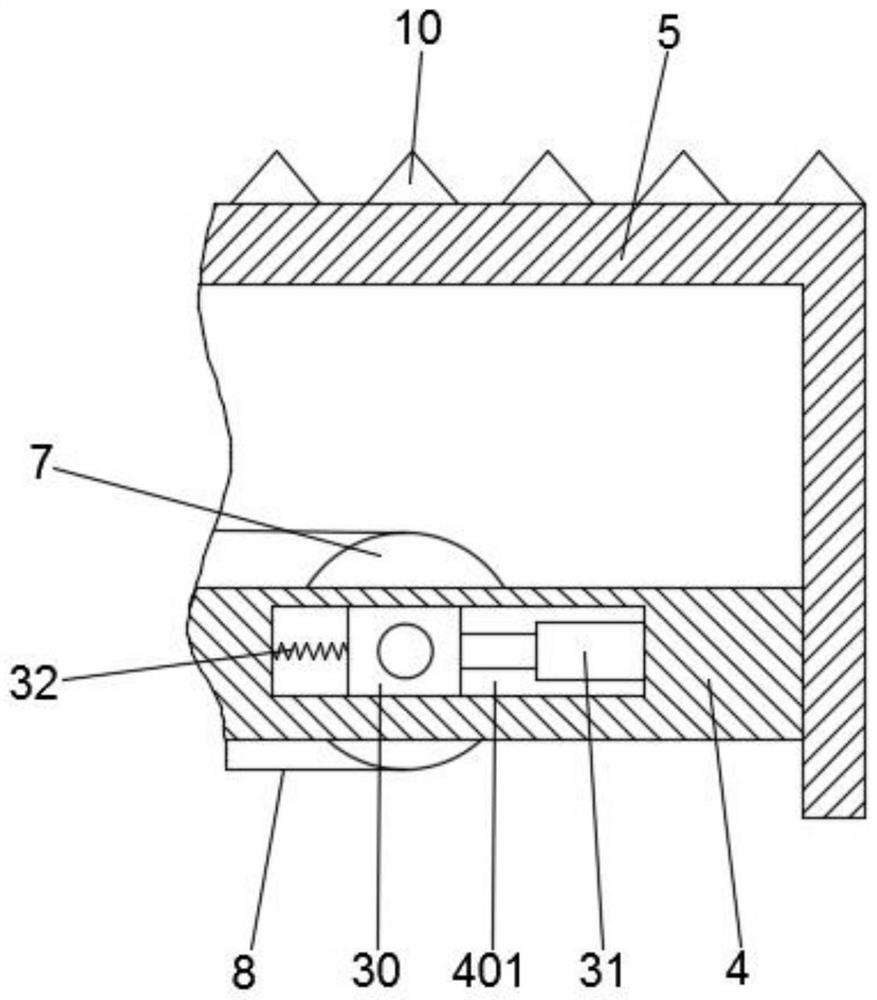

[0026] Such as Figure 1-3 As shown, a side unloader for bulk grain of a car comprises a base 1 and a grain collection box 9, the upper side of the base 1 is provided with a lifting column 2, and the top of the lifting column 2 is fixedly equipped with a support frame 3, and the support frame 3 is slidingly connected with a lower bracket 4, the upper side of the lower bracket 4 is fixedly connected with an upper bracket 5, and the middle part of the lower bracket 4 is provided with several groups of turning rollers 7, and the outer side of the turning rollers 7 is connected with a conveyor belt 8, The rotating roller 7 is driven by an external motor (not shown in the figure), and the conveyor belt 8 is provided with a discharge assembly away from the side of the lower support 4;

[0027] One end of the lower bracket 4 is provided with an adjustment assembly for adjusting the tightness of the conveyor belt 8 . The adjustment assembly includes a slider 30, a second electric pus...

Embodiment 2

[0033] Such as Figure 4 with Figure 5 As shown, the unloading assembly includes a base plate 18, a vertical plate 19, a baffle plate 20, a scraper 21 and a threaded rod 22. The middle part of the plate 20 is threadedly connected with a threaded rod 22, and the other end of the substrate 18 away from the conveyor belt 8 is fixedly connected with a vertical plate 19, and the end of the vertical plate 19 is hinged with a scraper 21, and the end of the scraper 21 is provided There is a chute, and one end of the threaded rod 22 close to the vertical plate 19 is slidably connected between the pin shaft and the chute, and one end of the scraper 21 is provided with a slot 2101, and an insertion rod 24 is slidably connected inside the slot 2101, A first spring 25 is fixedly connected between one end of the insertion rod 24 and the slot 2101, and a brush plate 29 is fixedly installed at the other end of the insertion rod 24, and both sides of the end of the insertion rod 24 close to ...

Embodiment 3

[0036] Such as figure 1 with Image 6 As shown, the bottom side of the lower support 4 is slidingly connected with several groups of third electric push rods 34, and the telescopic end of the third electric push rods 34 is fixedly connected with the grain storage box 9, and the grain storage box 9 is internally provided with Dividing plate 33, described dividing plate 33 one sides are provided with screen cloth 36, and the other side is provided with base plate 27, and described base plate 27 one end is hinged with 9 sidewalls of grain collection box, and the other end is in movable contact with dividing plate 33, and described Base plate 27 upper side is provided with weigher 35, and described grain collection box 9 bottoms are provided with first electric push rod 28, and the telescoping end of described first electric push rod 28 and base plate 27 are rotatably connected near dividing plate 33 one ends, so The middle part of the partition plate 33 is provided with a throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com