Forklift structure with adjustable axle distance

A forklift and wheelbase technology, applied in the direction of the lifting device, can solve the problems of moving the center of gravity upward, forklift forward tilt, tipping, etc., and achieve the effect of preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the invention is not limited to these embodiments.

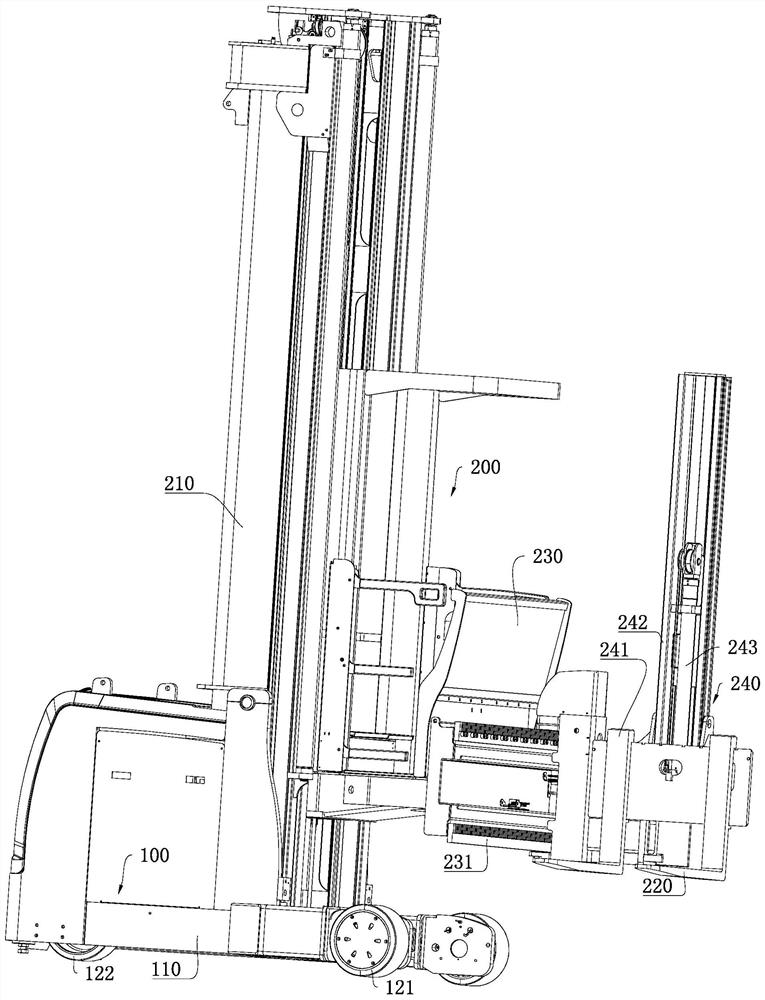

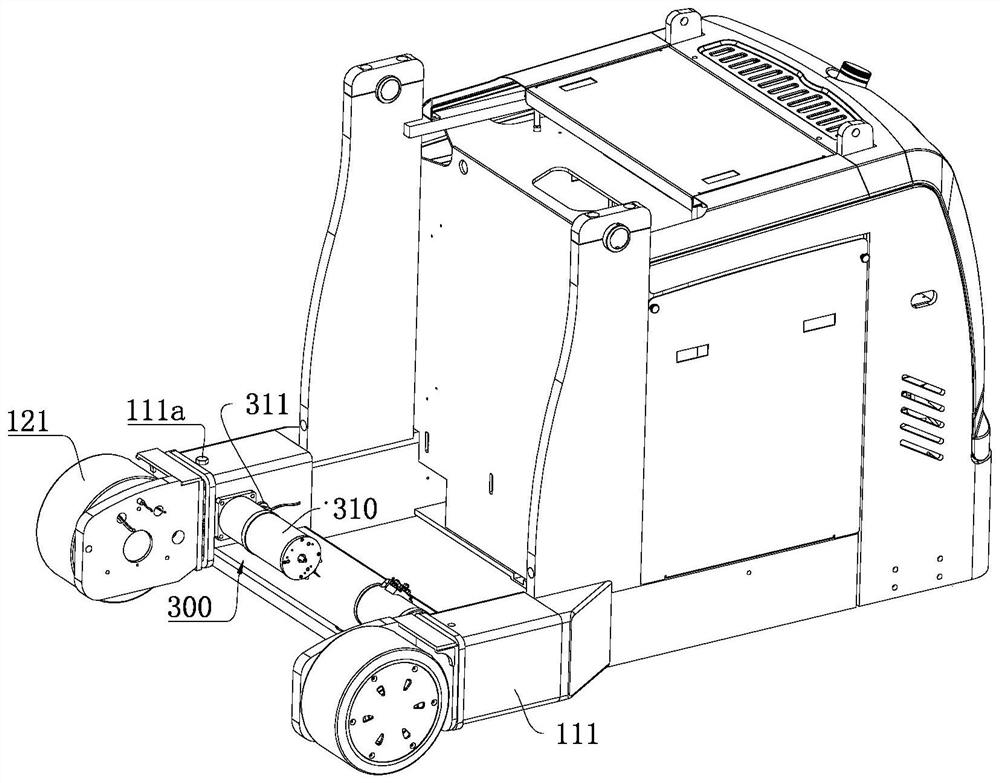

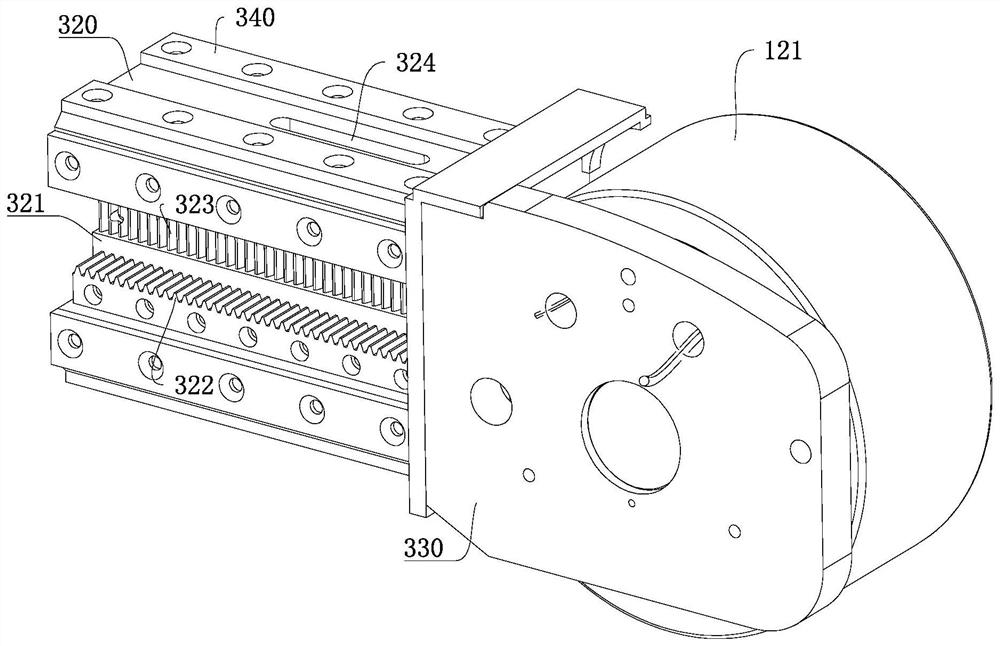

[0028] Such as Figure 1-3 As shown, a forklift structure with adjustable wheelbase, including:

[0029] The chassis system 100, the chassis system 100 includes a chassis 110 and a driving wheel set arranged under the chassis, the driving wheel set includes a front wheel 121 and a rear wheel 122, and the front wheel 121 and the rear wheel 122 are respectively arranged at the front and rear ends of the chassis 110, And the front wheel 121 has a first position close to the rear wheel 122 and a second position away from the rear wheel 122, that is, the wheelbase between the front wheel 121 and the rear wheel 122 is adjustable, and the longer the wheelbase, the more stable it will be during operation. better.

[0030] The mast syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com