Yarn tension adjusting mechanism of warp knitting machine

A technology for regulating mechanism and yarn tension, which is applied in warp knitting, textiles, papermaking, knitting, etc. It can solve the problem of uneven yarn tension and achieve uniform yarn tension and tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

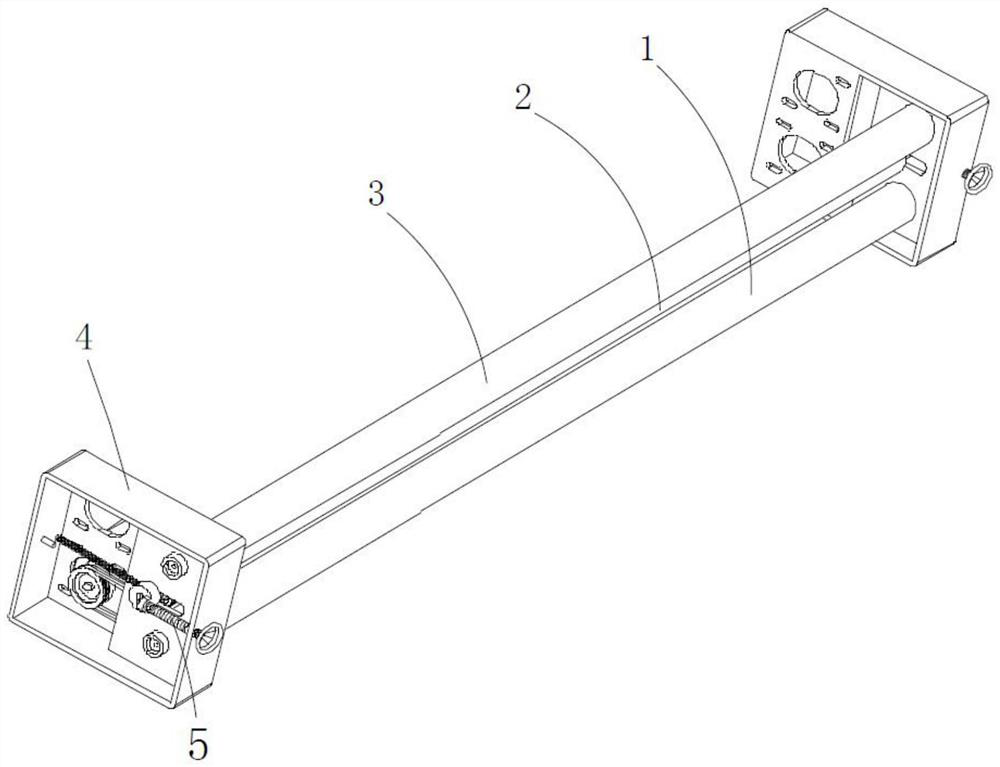

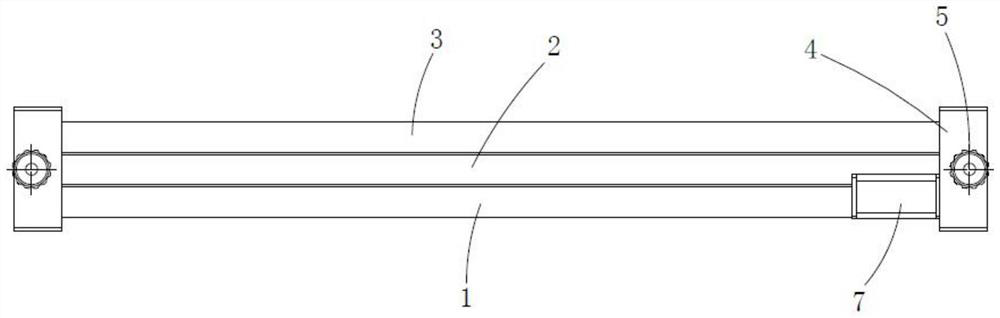

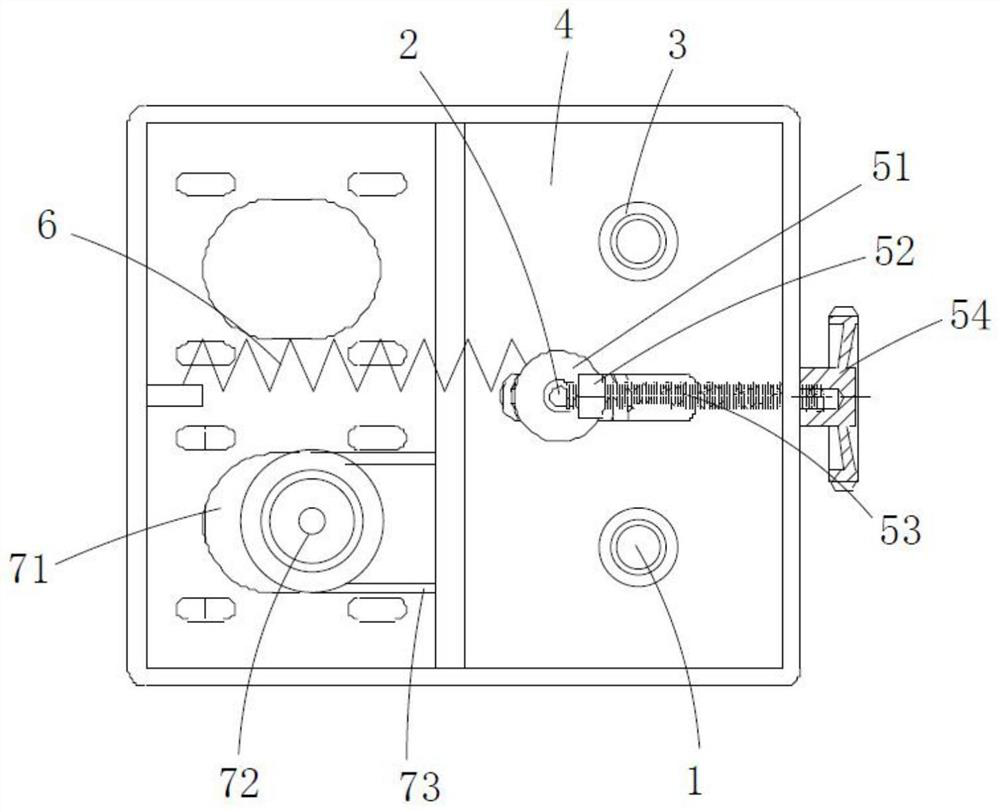

[0057] refer to Figure 1-3 , the present embodiment provides a warp knitting machine yarn tension adjustment mechanism, including a driving roller 1, a regulating roller 2 and a transition roller 3 arranged in sequence from top to bottom, and the regulating roller 2 moves left and right relative to the driving roller 1 and the transition roller 3 , the two ends of the driving roller 1, the regulating roller 2 and the transition roller 3 are all rotatably connected to the regulating mechanism 4; the driving roller 1, the regulating roller 2 and the transition roller 3 are arranged in a curve, and the driving roller 1 and the transition roller The axes between the 3 are on the same vertical line, wherein the yarn goes around the transition roller 3, the regulating roller 2 and the driving roller 1 in turn, so that the yarn is in the shape of a curve; the driving roller 1, the regulating roller 2 and the transition roller The surface of 3 is smooth, and the driving roller 1, reg...

Embodiment 2

[0067] refer to Figure 1-7 , this embodiment includes a transition roller 3 and a driving roller 1, the yarn reaches the transition roller 3 from the let-off mechanism, and the yarn is surrounded in an "S" shape from the side view between the transition roller 3 and the driving roller 1, thereby performing tension adjustment , the driving roller 1 mainly assists in pulling the yarn, and the original yarn itself has a certain pulling speed under the action of the pan head.

Embodiment 3

[0069] refer to Figure 1-7 , the difference between this embodiment and embodiment 2 is that the adjustment range of tension adjustment in embodiment 2 is relatively limited. In this embodiment, the driving roller 1 of embodiment 2 is replaced by the adjustment roller 2, and the adjustment roller 2 can be connected with the transition roller 3 presents an "S"-shaped wrapping angle with a large span for further tension control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com