Multi-shaft stirring pile construction equipment with stirring frame

A technology for construction equipment and agitating racks, applied in drilling equipment, drilling equipment and methods, sheet pile walls, etc., can solve problems such as insufficient mixing, achieve good pile forming effect, enhance strength and water-stop effect, and improve production efficiency. The effect of the pile stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

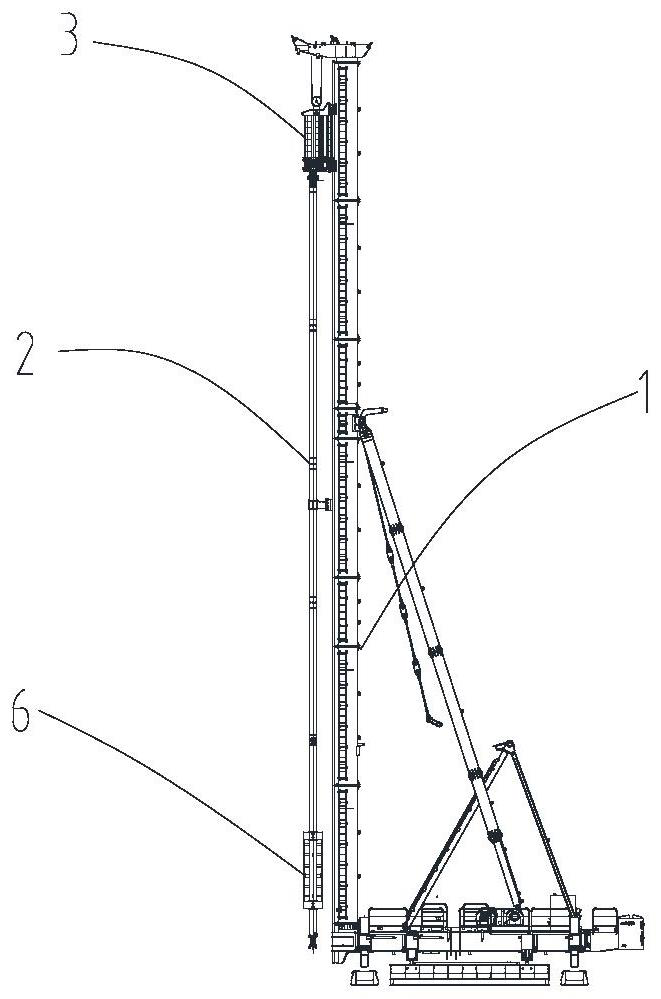

[0038] Example 1 figure 1 In this embodiment, the triaxial mixing pile apparatus includes a pile frame 1, a drill rod 2 is provided on a pile frame, and the drill rod 2 is used to form a cement soil mixing pile; the drill rod 2 is installed with power head 3, and the power head 3 is installed Motor. A mixing frame 6 is provided at the front end of the drill pipe.

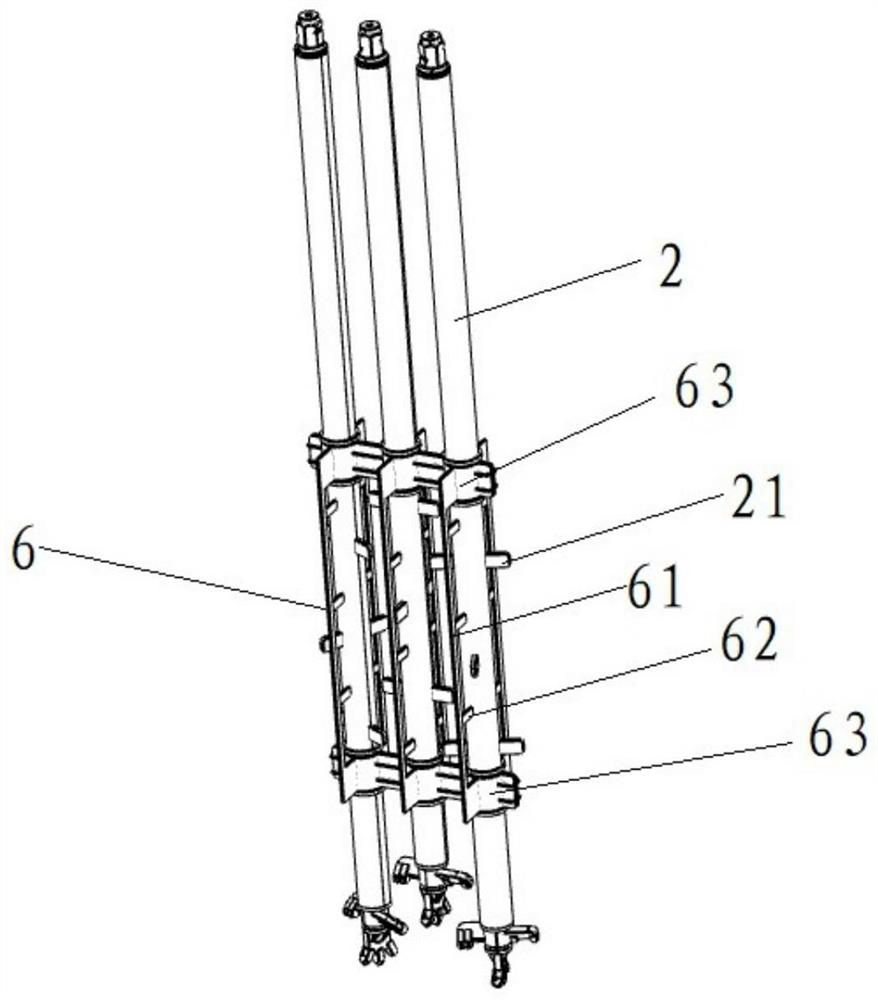

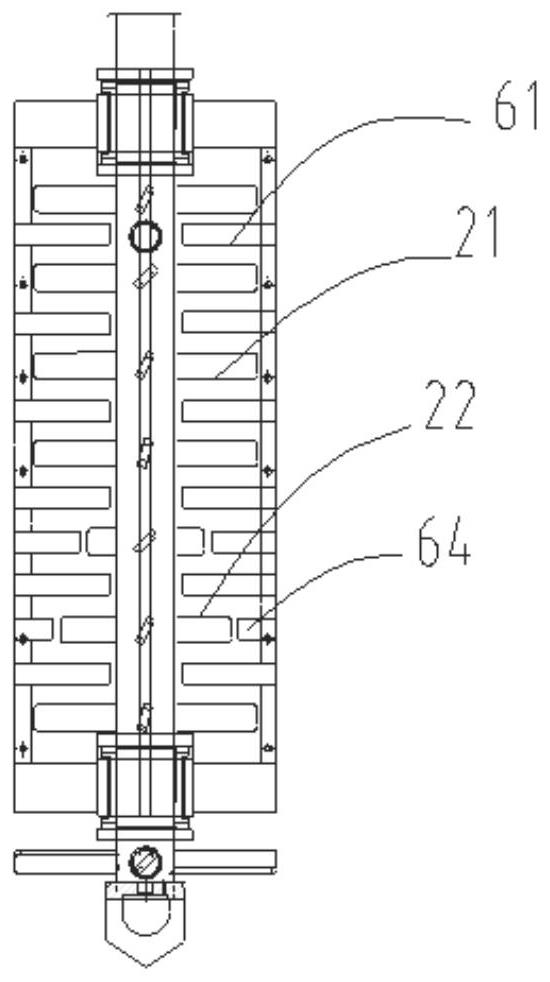

[0039] See figure 2 The mixing frame 6 is a vertical frame structure, and the frame structure is connected to the drill pipe through the bushing 63, and the frame structure comprises six stirring frames 61, i.e., two mixing frames on each drill pipe, each stirring frame 63 is "]", The shaft sleeve 63 of the plurality of drill pipes is connected by a casing, each of which is coupled to the sleeve 63, respectively.

[0040] Alternatively, the mixing frame 6 is a hollow cage, and is sleeved in the lower portion of the drill pipe, and the portion of the drill pipe is provided, and the stirring blades 61 are provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com