Integrated assembly type steel structure building and assembly method thereof

A steel structure and assembly technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of low work efficiency, rainwater penetration, and flushing out gaps, etc., so as to shorten the working time, reduce the working intensity and improve the sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

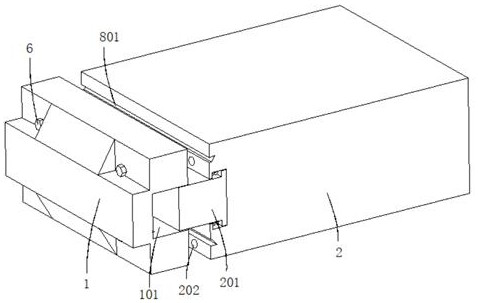

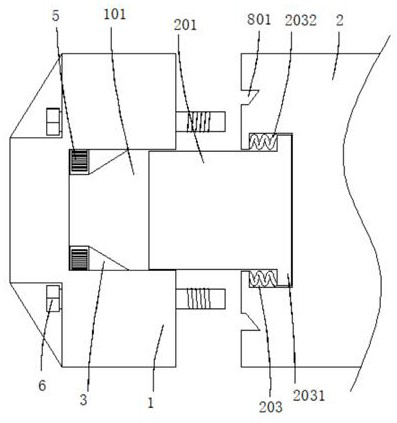

[0039] refer to figure 1 , figure 2 , image 3 and Figure 9, an integrated assembled steel structure building, including a steel structure beam 1 and an installation wall panel 2, the outer wall of the steel structure beam 1 is provided with a socket 101, and the outer wall of the installation wall panel 2 is connected with a socket 201 matching the socket 101, and the socket 101 A sealing mechanism for filling gaps is provided inside, and a locking mechanism for fixing the steel structure beam 1 and installing the wallboard 2 is also arranged in the socket 101, and the sealing mechanism drives the locking mechanism to work.

[0040] In the present invention, during the process of inserting the wallboard 2 and the steel structure beam 1, that is, inserting the plug block 201 into the socket 101, the fixing of the two can be realized, the overall stability of the steel structure is improved, and the working time is shortened. The working intensity is reduced, and the seali...

Embodiment 2

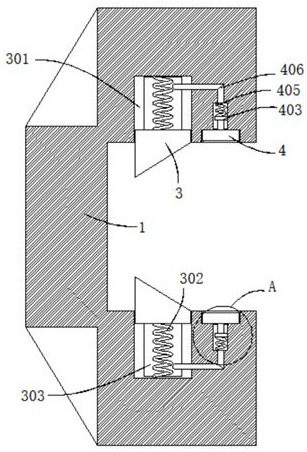

[0042] refer to figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 10 , an integrated fabricated steel structure building, which is basically the same as that of Embodiment 1, furthermore, the sealing mechanism includes a force driving component and a sealing component, and the force driving component includes a force block 3, a force block 3 and an inserting block 201 moves against each other, and the inner wall of the socket 101 is drilled with a movable groove 301 matching the force-bearing block 3 , and a first elastic element 302 and an air bag 303 are connected between the force-bearing block 3 and the inner wall of the movable groove 301 .

[0043] Further, the sealing assembly includes a fixed plate 4 for clamping the plug 201, the outer wall of the fixed plate 4 is connected with a rubber pad 401, the side of the fixed plate 4 away from the rubber pad 401 is connected with a connecting rod 402, and the outer wall of the connecting rod 402 is conn...

Embodiment 3

[0047] refer to figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , an integrated assembled steel structure building, which is basically the same as Embodiment 2, furthermore, the locking mechanism includes a rack plate 5 fixed on the outer wall of the force block 3, and the rack plate 5 is slidably connected to the steel structure beam 1, the outer wall of the rack plate 5 is meshed with a first gear 501, the first gear 501 is fixedly connected with a sleeve 502, the inner wall of the sleeve 502 is detachably connected with a fastening bolt 6, and the outer wall of the installation wall plate 2 is excavated. The threaded hole 202 that fastening bolt 6 cooperates.

[0048] Further, the outer wall of the installation wallboard 2 is dug with a moving groove 203, the inner wall of the moving groove 203 is slidably connected with a moving plate 2031, and a third elastic element 2032 is connected between the moving plate 2031 and the inner wall of the moving groove 203...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com