Shaking type cleaning device for environment-friendly material

An environmentally friendly material and cleaning device technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of automatic realization and low effect, so as to ensure the degree of mixing, improve the cleaning effect, and improve The effect of immersion cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

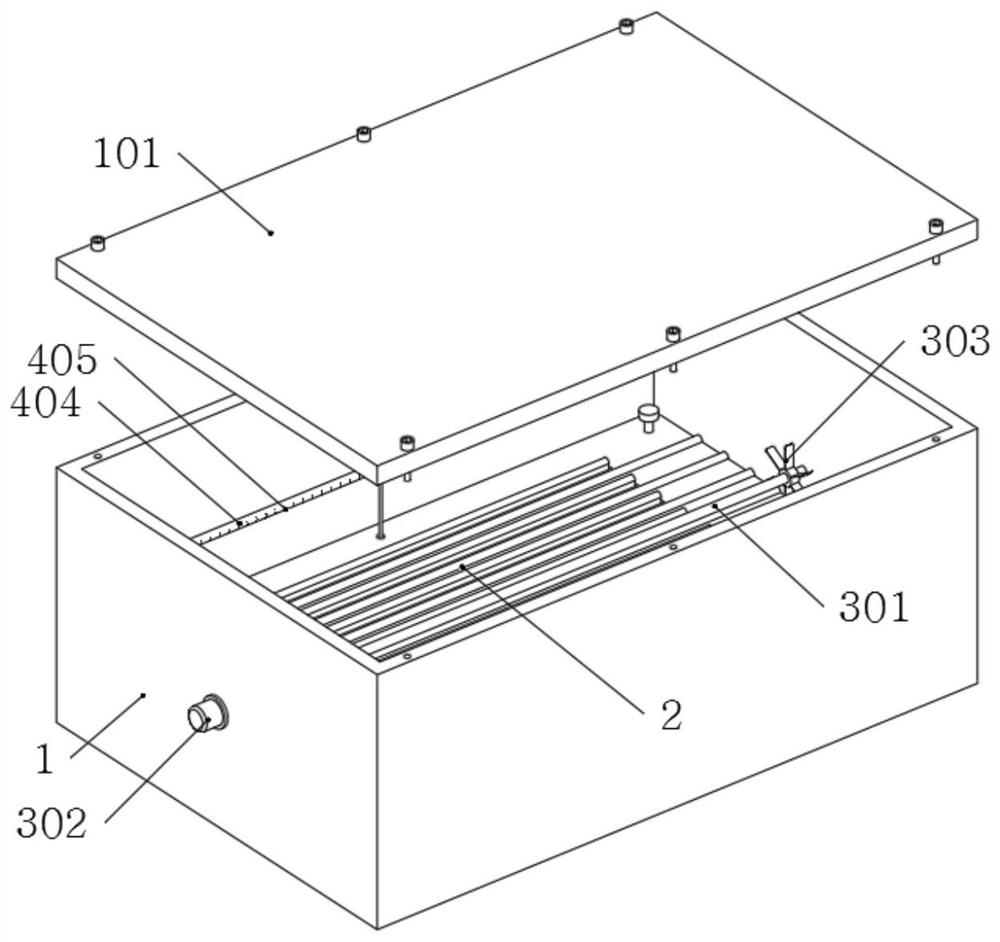

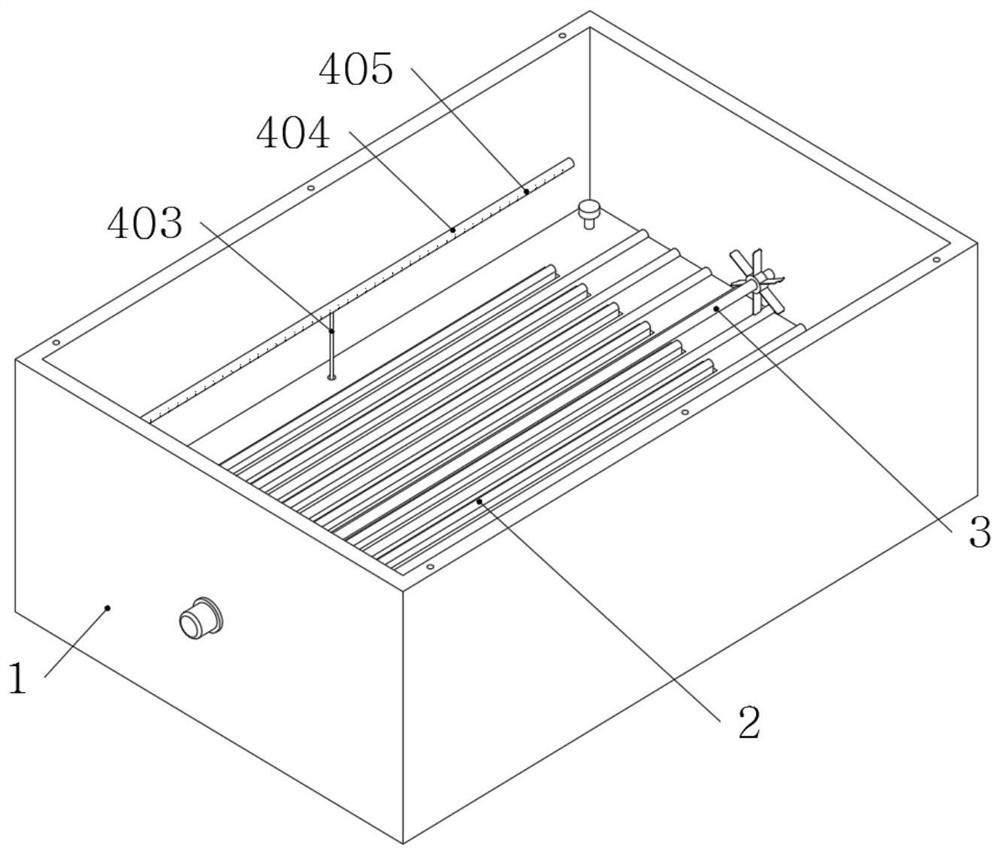

[0040] The present invention provides a shaking type cleaning device for environmental protection materials, which includes a box body 1, a placement part 2 and a drive part 3; the box body 1 is placed on the ground, and a cover plate 101 is fixedly connected to the box body 1 by bolts; Placement part 2 is made up of slide bar 201, place plate 202, elastic member 203, through hole 204 and protrusion 205, and slide bar 201 is provided with four altogether, and four slide bars 201 are all welded in casing 1; The part 3 is composed of a rotating shaft 301 , a driving motor 302 and an impeller 303 , and the rotating shaft 301 is rotatably connected to the box body 1 .

[0041] Reference as Figure 5 and Figure 6, the placement plate 202 is slidably connected to the four sliding rods 201, and each sliding rod 201 is sleeved with an elastic member 203; It is in elastic contact with the bottom end surface of the box body 1, and the four elastic pieces 203 together form the elastic...

Embodiment 2

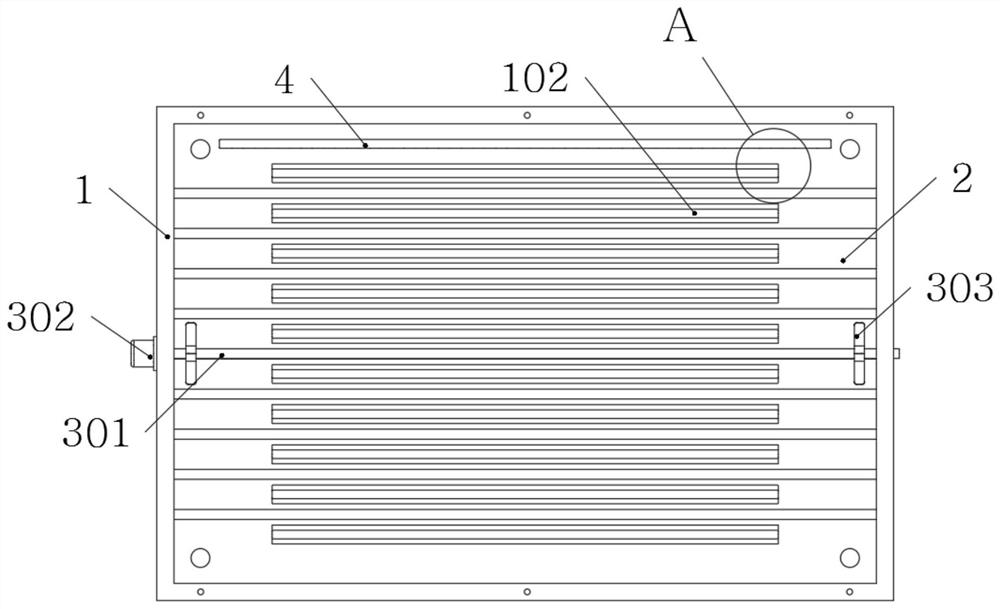

[0049] A shaking cleaning device for environmentally friendly materials, including a box body 1; ten auxiliary plates 102 are welded in a rectangular array in the box body 1, and the auxiliary plates 102 are aligned with the through holes 204, and when the plate 202 is placed When moving down, the auxiliary plate 102 is exposed, thereby realizing the switch of the placement position of the environmental protection material, and then avoiding the dead angle of cleaning.

[0050] Reference as Figure 8 , The head end of the auxiliary board 102 has an arc-shaped structure, thereby reducing the contact area between the head end of the auxiliary board 102 and the environmental protection material.

[0051] Reference as image 3 , Figure 4 Figure 11 and Figure 12 , the width of the auxiliary plate 102 is smaller than the width of the through hole 204, so as not to affect the normal water spray at the through hole 204.

[0052] The specific usage and function of this embodime...

Embodiment 3

[0056] A sloshing type cleaning device for environmentally friendly materials, including an auxiliary part 4; the auxiliary part 4 is composed of a piston bottle 401, a water inlet pipe 402, a connecting pipe 403, a spray pipe 404 and a spray hole 405, and the piston bottle 401 is fixedly connected by bolts In box 1.

[0057] Reference as Figure 5 and Figure 10 , the water inlet pipe 402 and the connecting pipe 403 are all connected to the piston bottle 401, and the top of the piston bottle 401 is in elastic contact with the placement plate 202; To the valve, so that when the piston bottle 401 completes a stretch, the water inlet pipe 402 completes a water suction action, and the connecting pipe 403 completes a water spray action.

[0058] Reference as Figure 5 , the nozzle 404 is connected to the connecting pipe 403, and the nozzle 404 is a cylindrical tubular structure, and the nozzle 404 is provided with a fan-shaped array of nozzle holes 405, so that the cleaning liq...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap