Powder storage equipment for powder metallurgy

A storage device and powder metallurgy technology, applied in the field of powder metallurgy, can solve the problems of affecting the quality of formed products, poor storage effect, and inability to effectively screen powder materials, etc., achieve high practicability and market prospects, facilitate storage, and improve drying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

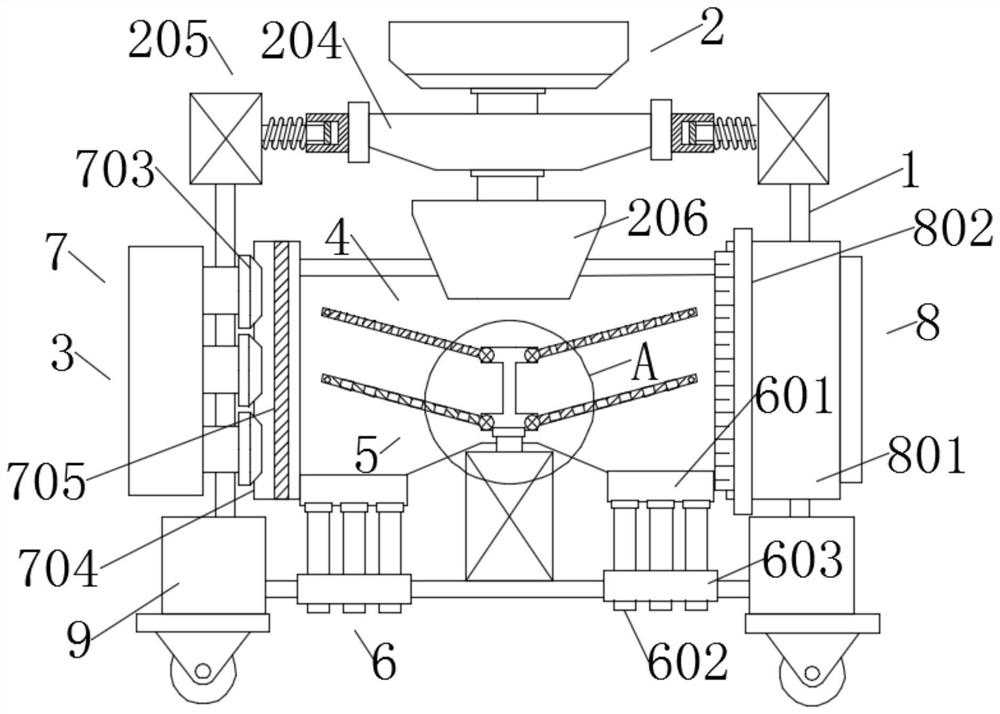

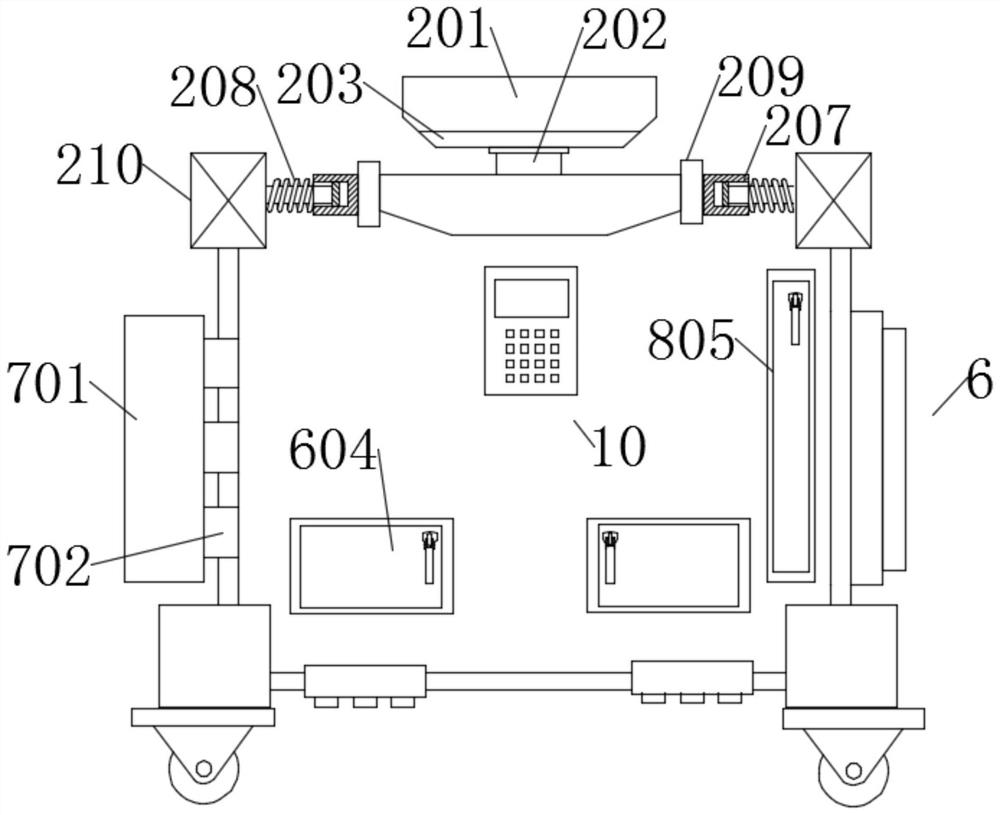

[0024] see Figure 1~4 , in an embodiment of the present invention, a powder storage device for powder metallurgy, including a housing 1, a feeding device 2 is installed above the middle of the housing 1, and the feeding device 2 can screen the powder before storage, A storage bin 4 is arranged inside the housing 1, and a circulation drying device 3 used in conjunction with the storage bin 4 is provided in the middle of the housing 1, and the circulation drying device 3 can carry out the Circulating flow drying prevents uneven drying effect of internal materials during the drying process and forms a humidity ladder. A stirring device 5 used in conjunction with the circulating drying device 3 is also installed inside the storage bin 4. The stirring device 5 The internal powder can be stirred and mixed to further improve the drying effect and facilitate storage. A feeding device 6 is respectively installed on the left and right sides of the bottom of the storage bin 4, and a fee...

Embodiment 2

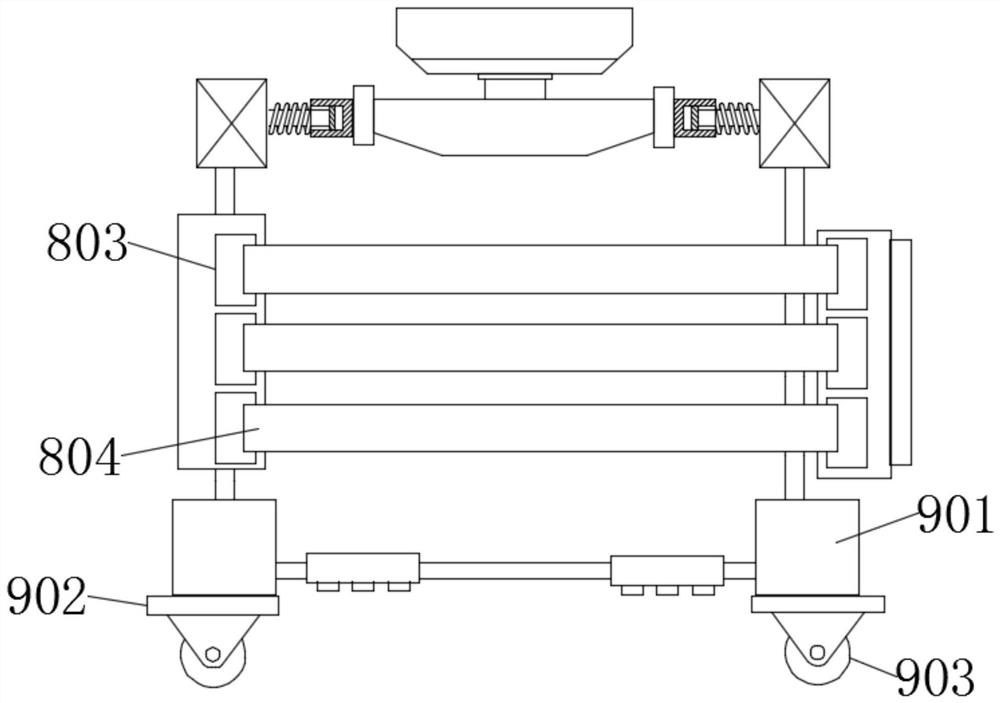

[0026]In this embodiment, the circulating drying device 3 includes an air intake device 7 and an exhaust device 8 , the air intake device 7 is connected and installed outside the left side of the casing 1 , and the exhaust device 8 is connected and installed on the right side of the casing 1 Outside the side, the air intake device 7 is used in conjunction with the exhaust device 8 to form an annular circulating air flow; the air intake device 7 includes an air intake fan 701, three air intake pipes 702, three air inlets 703, and an air bin 704 With the electric heating sheet 705, the air bin 704 is connected and installed on the left side of the storage bin 4, and the three air inlets 703 are connected and installed outside the air bin 704. The air intake fan 701 is connected with the air inlet 703 through the air inlet pipe 702, and the electric heating The sheet 705 is inserted in the inner side of the air bin 704. During operation, the air intake fan 701 blows the airflow to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com