Special-shaped beam butt welding tool for green building construction

A green building, welding tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor practicability, affecting reuse, end ring damage, etc., to achieve easy installation and disassembly, and easy to repeat. Use, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

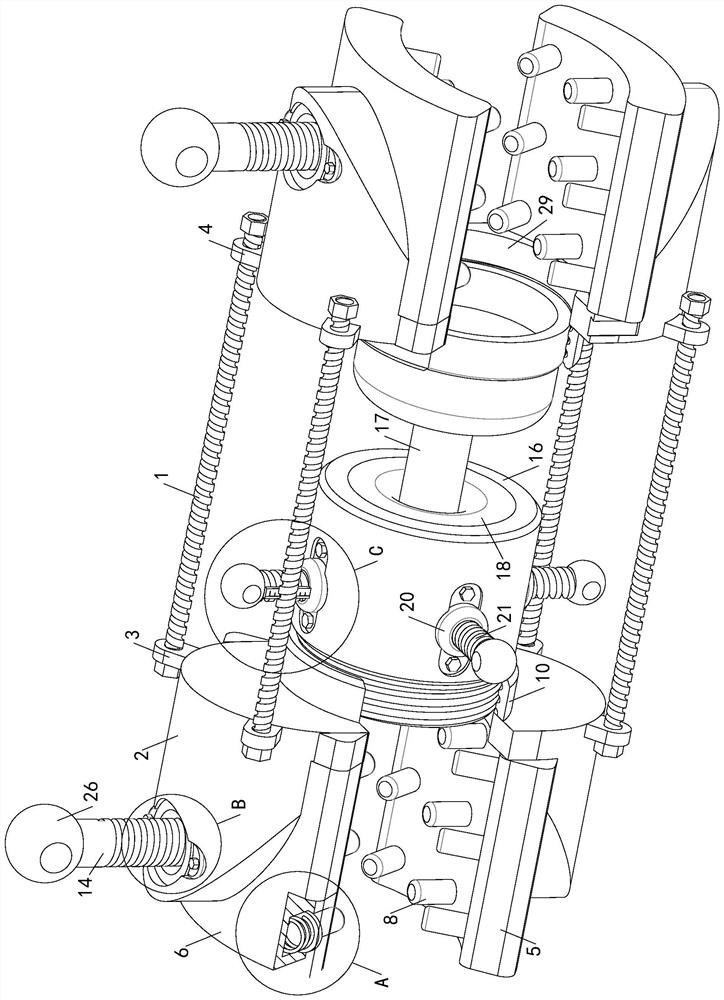

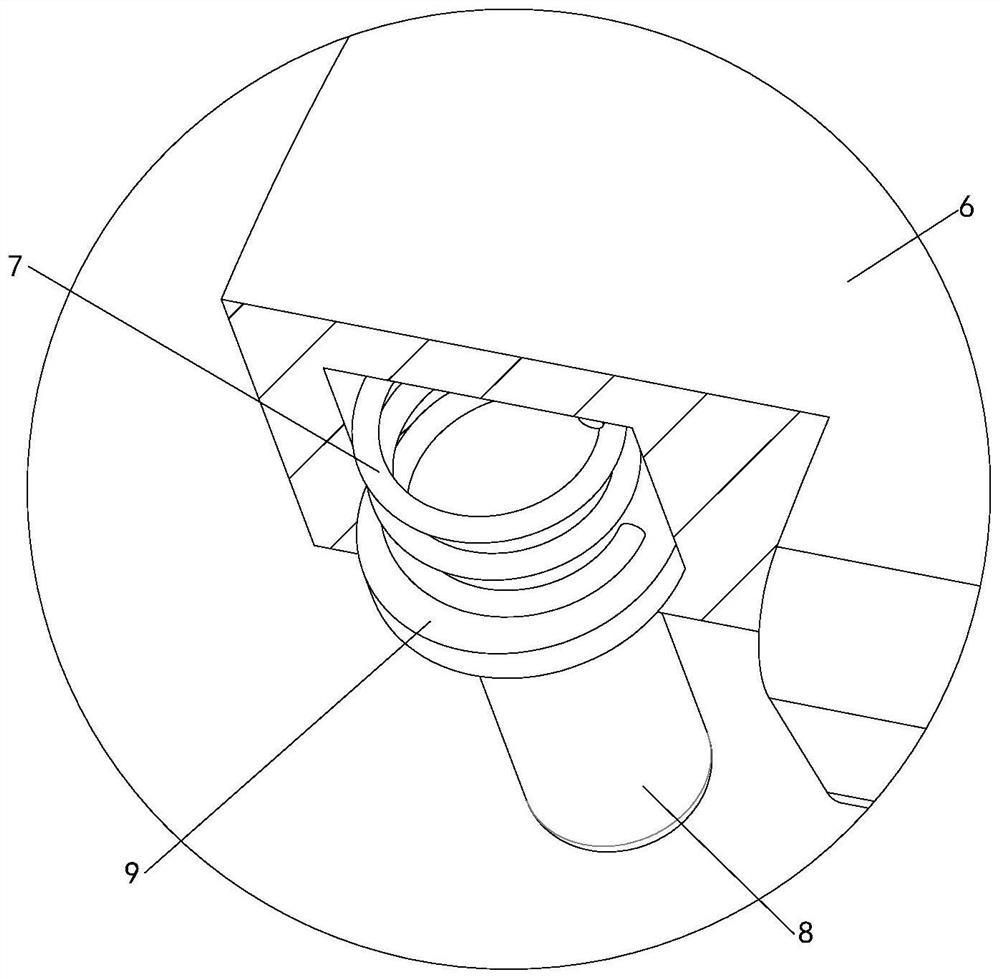

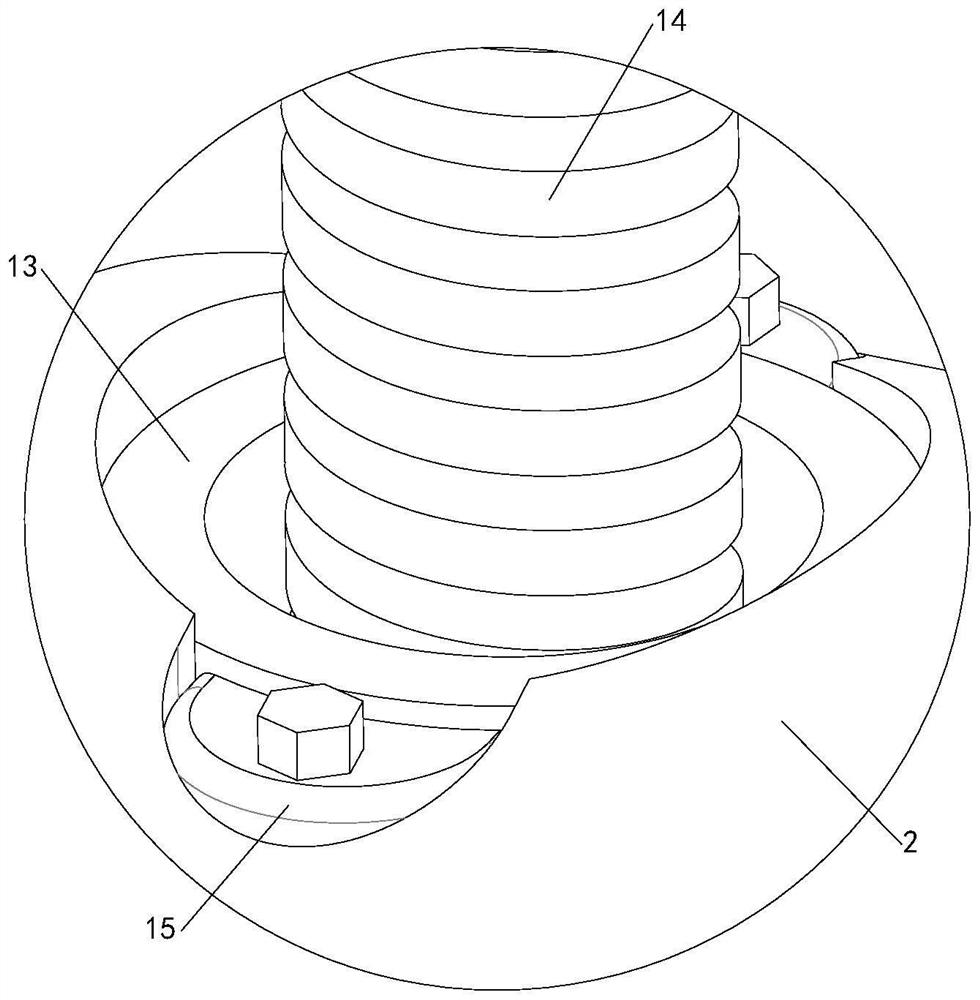

[0031] see Figure 1-7 , a special-shaped beam butt welding tool for green building construction, including a plurality of draw bolts 1, and also includes two mounting brackets 2, and the two mounting brackets 2 are respectively fixedly connected with a plurality of left pulling lugs 3 and a plurality of right pulling lugs 4. Both the left traction ear 3 and the right traction ear 4 are provided with circular holes, the traction bolts 1 are set in the circular holes, the two mounting frames 2 are fixedly connected with the fixing plate 5, and the two mounting frames 2 are slidingly connected with the The adjusting plate 6, through the cooperation of the fixing plate 5 and the adjusting plate 6, facilitates the compaction of various sizes of special-shaped beams. There is a dovetail rail 24 slidingly connected in the groove, and the dovetail rail 24 is fixedly connected with the adjusting plate 6 through the connecting block 25, so as to realize the sliding connection between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com