Normal detection method for pressure foot contact surface as conical surface

A pressure foot and contact surface technology, applied in the direction of comprehensive factory control, measuring/indicating equipment, manufacturing tools, etc., can solve the problems of low precision, sensor wear, large friction, etc., and achieve simple and fast algorithm, good measurement accuracy, and robustness good sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

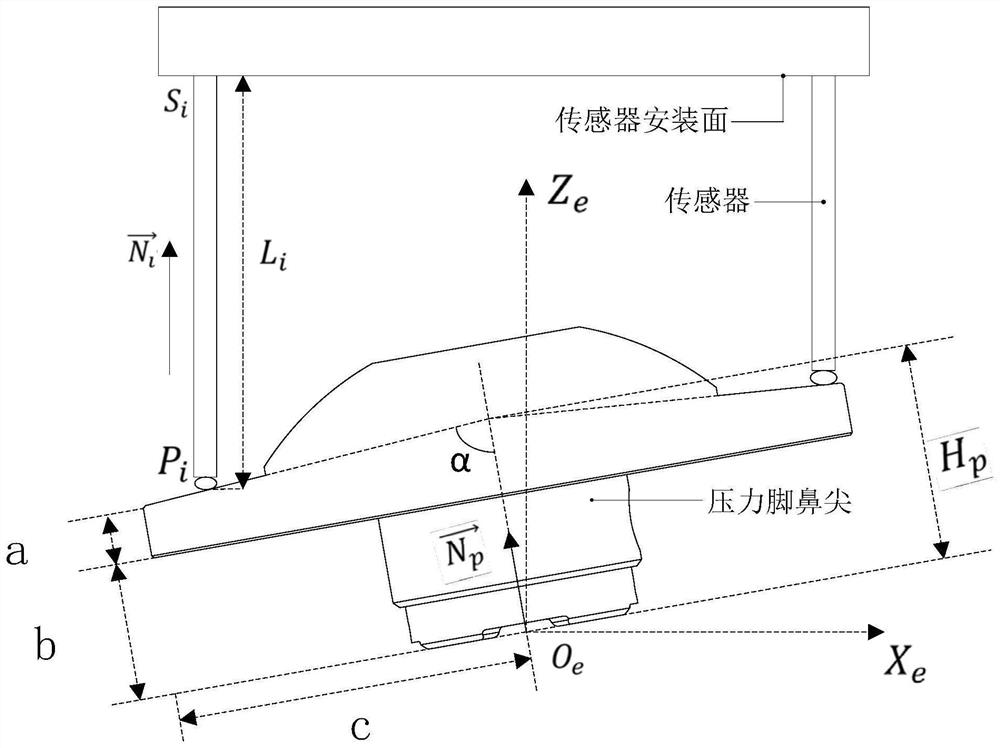

[0041] Such as Figure 1-3 shown.

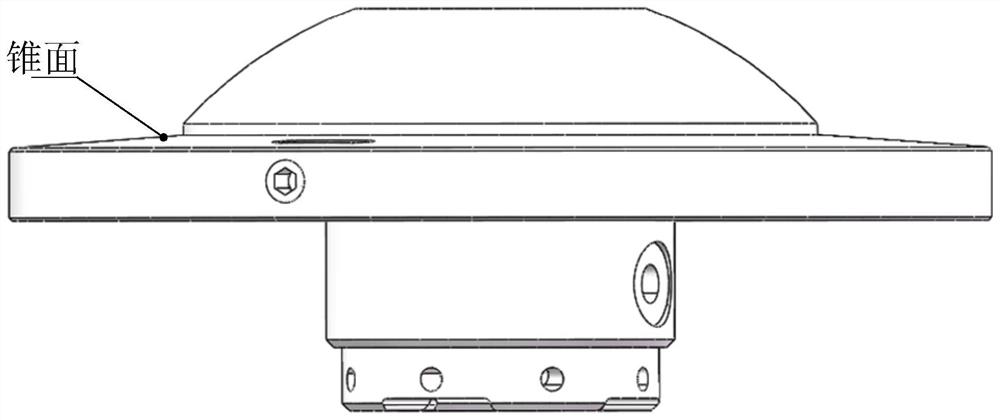

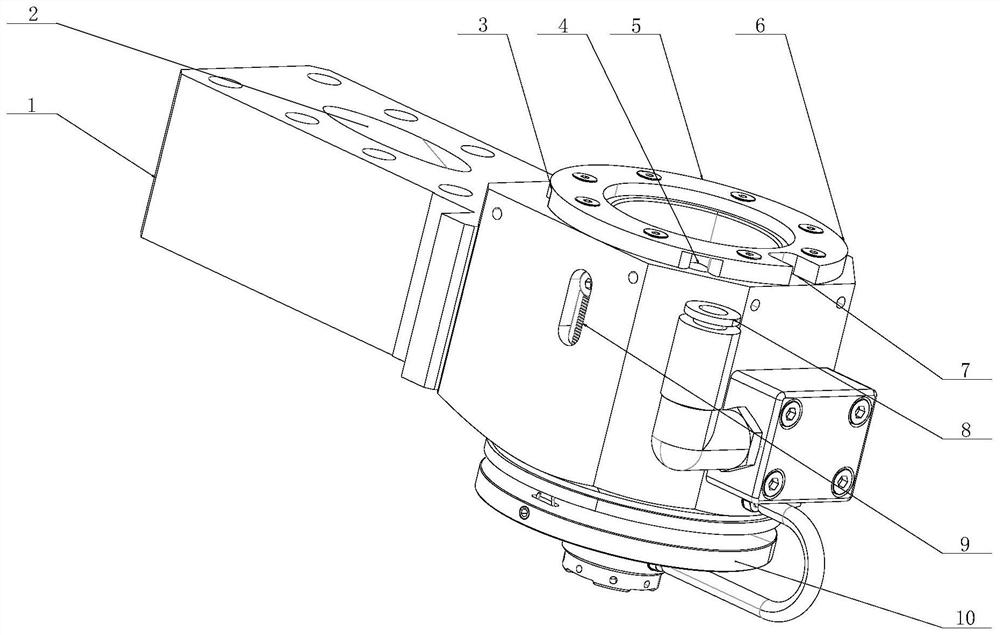

[0042] In this embodiment, the contact measurement surface of the tip of the pressure toe is the quadratic surface of the cone ( figure 1 ) contact pressure foot ( figure 2 ) provides a normal direction detection method, which has the advantages of simple algorithm and easy and fast calibration of parameters. For quadratic surfaces such as conical surfaces such as arc surfaces, it can be implemented as a reference.

[0043] The structure of the pressure foot used in this embodiment is as follows: figure 2 As shown, it includes a pressure foot main body 1, a quadratic surface measuring surface pressure toe nose tip 10; a quadratic surface measuring surface pressure toe nose tip 10 is fixed on the pressure foot main body 1 through a connecting spring 9; normal detection sensors 3, 4, 5 , 6 are installed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com