Intelligent automatic car washing robot

An automatic car washing and robot technology, applied in vehicle maintenance, vehicle cleaning, vehicle drying devices, etc., can solve the problems of high maintenance cost, low service life, car paint damage, etc., to reduce equipment costs and equipment maintenance costs, high efficiency The effect of high-quality car wash and equipment cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

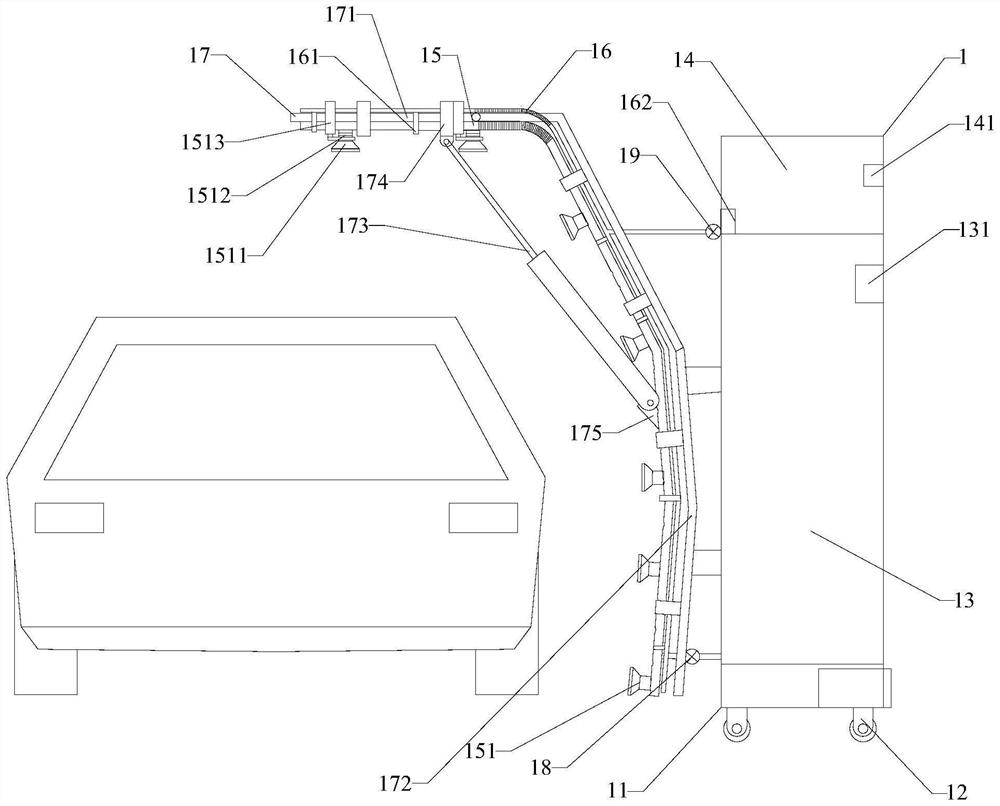

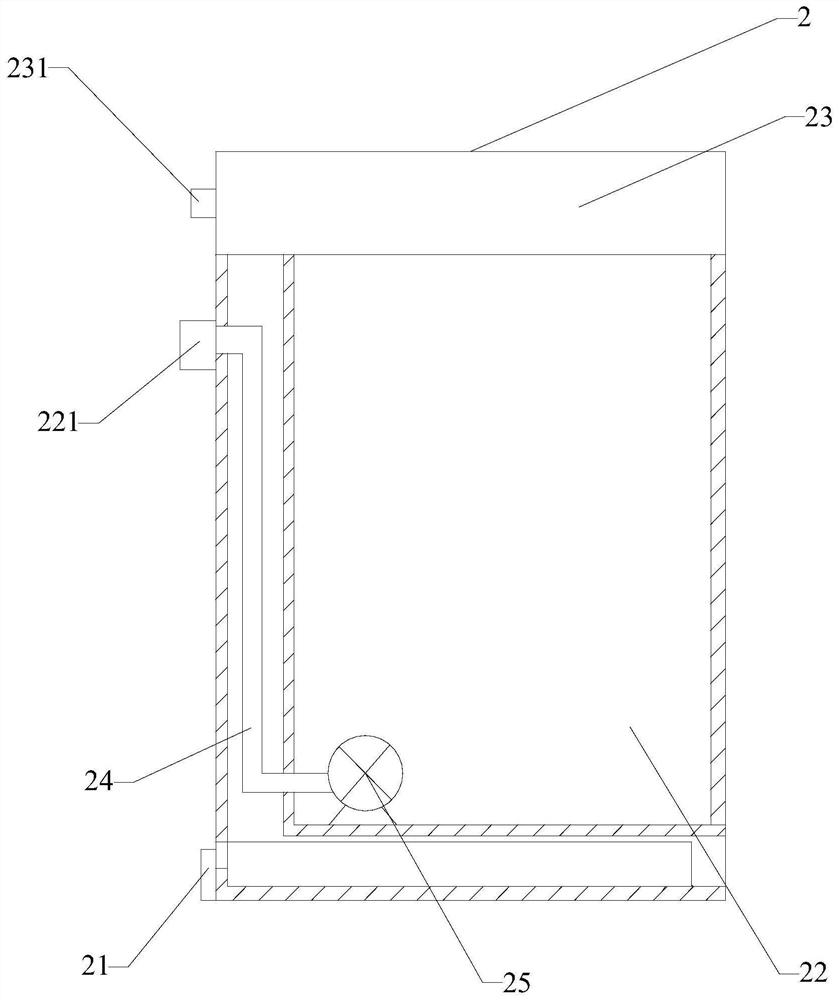

[0055] Please refer to figure 1 as well as figure 2, an intelligent automatic car washing robot, including a supply connection seat 2 and a car washing robot body 1; the car washing robot body 1 includes a base 11, a moving mechanism 12, a lithium battery, an automatic control module, a first water tank 13, a first cleaning Liquid storage tank 14, spray pipe 15, cleaning liquid spray pipe 16, support frame 17, first liquid pump 18, second liquid pump 19 and hot air blower; Described lithium battery is connected with first liquid pump 18, the second liquid pump respectively. The pump 19 is electrically connected to the automatic control module, and the automatic control module is electrically connected to the first liquid pump 18, the second liquid pump 19 and the moving mechanism 12 respectively; the automatic control module is used to control the moving mechanism 12 according to a pre-planned path The automatic control module is used to drive the opening or closing of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com