A method for heat balance control of fully hot copper matte blowing

A control method and heat balance technology, applied in the field of continuous copper smelting, can solve problems such as inability to achieve heat balance control and inability to stabilize production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] In this embodiment, the heat balance of the full-heat state continuous blowing is controlled by controlling the flow rate of nitrogen doping.

[0078] In bottom-blowing furnace continuous feed blowing and periodic copper discharge, the heat balance control process in the cycle is as follows:

[0079] The grade of raw material hot matte is 74.5%, and the feed flow rate is 0.4t / min. The size of the bottom blowing furnace body is Φ5.2m*23m.

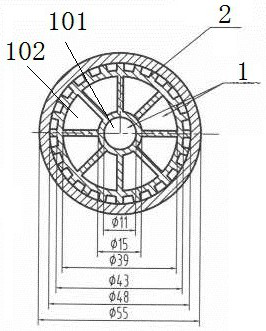

[0080] The structure and layout of the blowing oxygen lance are as follows: the blowing oxygen lance has inner pipes 1 distributed along the circumferential direction at intervals (that is, the central pipe 101 and intermediate pipes 102 distributed along the outer circumferential direction of the central pipe 101), and the inner pipes 1 distributed along the outer circumferential direction. Outer pipes 2 distributed at intervals, such as image 3 As shown, the area ratio of the total ventilation section of the inner pipeline 1 to the...

Embodiment 2

[0085] In this embodiment, the heat balance of the full-heat state continuous blowing is controlled by controlling the flow rate of nitrogen doping and adding cold material in a synergistic manner.

[0086] Specifically, proceed according to the method of Example 1. The difference is that during the periodical blowing process, the temperature of the slag layer also rises to above 1235°C, and the temperature of the blister copper layer rises to above 1245°C. At this time, In the bottom blowing furnace, 30t of cold material is also added, which is the anode butt. The total blowing time was 5 hours and 35 minutes.

[0087] After periodic copper discharge, the grade of blister copper is 98.12%.

Embodiment 3

[0089] In this embodiment, the heat balance of the full-heat state continuous blowing is controlled by controlling the flow rate of nitrogen doping, adding cold material and controlling the grade of hot matte.

[0090] Carry out according to the method of embodiment 2, the difference is that in the periodic blowing process, the temperature of the slag layer also rises to above 1235°C, and the temperature of the blister copper layer rises to above 1245°C, at this time, the control The grade of raw material hot matte is 75%-76%. The total blowing time was 5 hours.

[0091] After periodic copper discharge, the crude copper grade is 98.0%.

[0092] Known by above-mentioned embodiment, adopt the heat balance control method of the present invention, can realize full-heat state continuous blowing method, and the blister copper obtained, and the technology of the mixed production of existing cold and hot state matte (the crude copper that it makes Copper grade is generally lower tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com