Teaching equipment operation and maintenance system and working method thereof

An operation and maintenance system and equipment technology, applied in educational appliances, teaching models, instruments, etc., can solve problems such as inability to systematically learn and poor teaching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

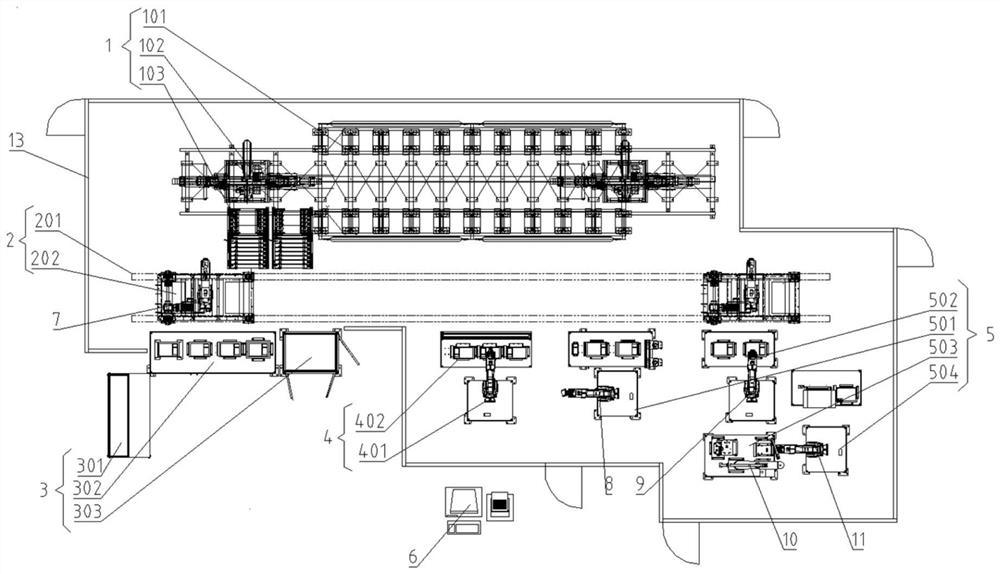

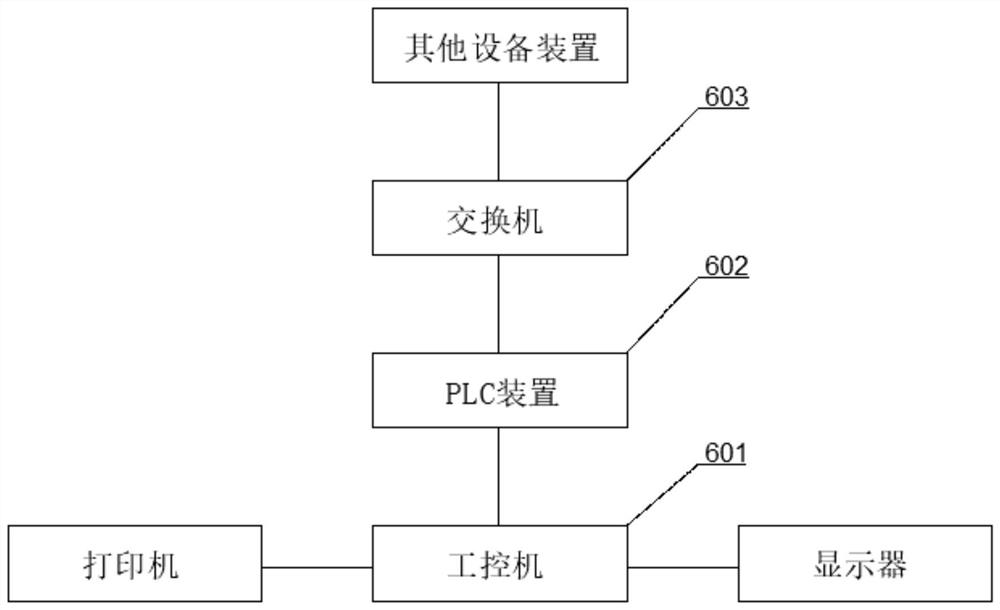

[0031] Such as Figure 1-2 As shown, a teaching equipment operation and maintenance system includes a storage module 1, a transportation module 2, a detection module 3, a drawing module 4, an assembly module 5, and a system control module 6. The system is provided with a fence 13, and the fence 13 surrounds the storage module 1. The transportation module 2, the drawing module 4 and the assembly module 5, and the fence 13 are used to isolate the operator from the automation equipment to ensure the safety of personnel during production. In order to further ensure personal safety, gratings are installed on the fence 13 of the system entrance (near the detection module 3) and exit (near the assembly module 5). Intervene in the working area of the grating, and the robot operation is suspended to ensure the safety of personnel. The storage module 1, the transportation module 2, the detection module 3, the drawing module 4, the assembly module 5 and the system control module 6 tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com