Device and method for removing magnetism of pins of circuit board components for spaceflight

A component and circuit board technology, applied in the field of magnetic removal of board component pins, can solve problems such as non-standard, solder joint failure, undeveloped demagnetization device and method, etc., to improve welding level, reduce quality problems, The effect of risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0023] The invention provides a device for removing magnetism from pins of circuit board components used in aerospace and a method for using the same, which not only can significantly improve welding quality and reduce the risk of false welding, but also has the characteristics of simple operation and good economy.

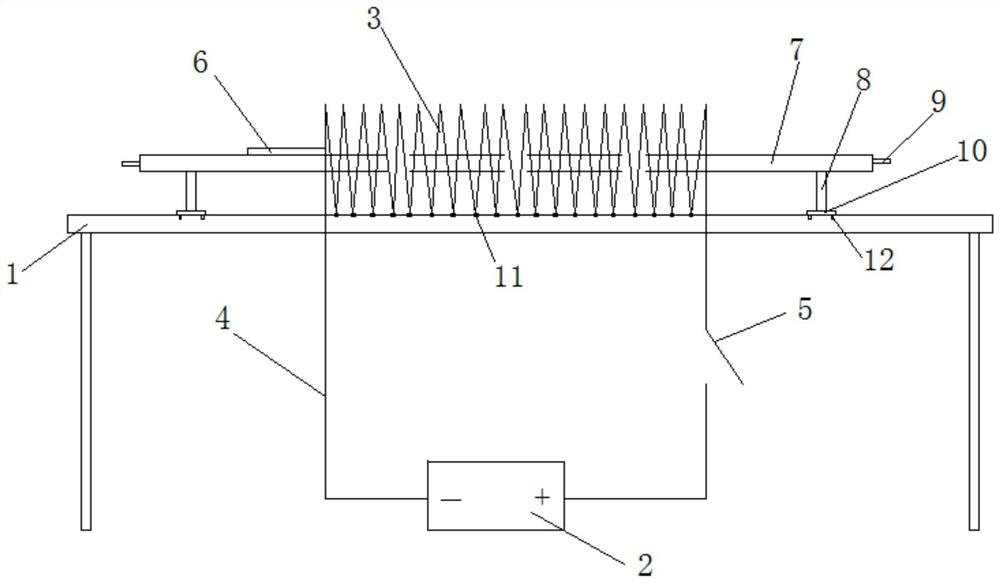

[0024] The present invention provides a device for magnetically removing pins of aerospace circuit board components, including: an insulating table 1, a power supply 2, a winding coil 3, a wire 4, a switch 5, an insulating tray 6, an insulating track 7, and a track support 8 , rocker 9, positioning base 10, coil fixing card 11, connecting bolt 12 and other devices, such as figure 1 shown.

[0025] The insulating table 1 is connected to the track support 8 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com