Ventilation floor capable of automatically adjusting temperature for machine room

An automatic adjustment and ventilation panel technology, which is applied to local raised floors, cooling/ventilation/heating renovation, floors, etc., can solve problems such as insufficient cooling of cabinets, overcooling of cabinets, energy waste, etc., to increase the amount of cold air and reduce Resistance, ensure the driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

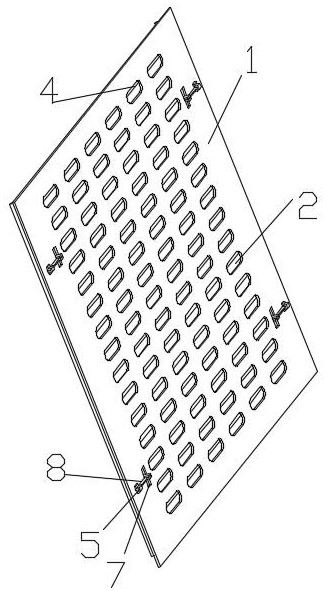

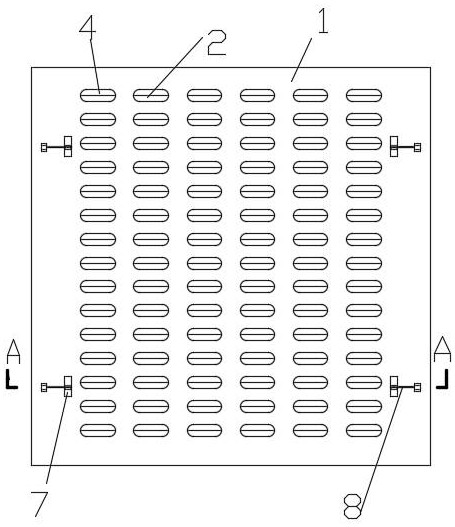

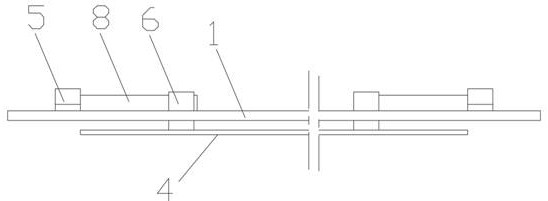

[0019] Example 1, such as figure 1 , 2 As shown in and 3, metal materials are used to set up the frame at the bottom of the machine room, and a ventilation plate is laid on the frame to form the load-bearing surface of the cabinet. The central area of the ventilation plate 1 is provided with a number of ventilation holes 2 evenly arranged. The shape of the ventilation holes 2 is long The grille plate 4 is arranged under the ventilation plate 1, the upper end surface of the grille plate 4 is attached to the lower end surface of the ventilation plate 1 (there is a gap and does not touch), and the driving device is installed on the ventilation plate 1. The driving device described above is a thermal bimetallic sheet 8 with different thermal expansion and contraction rates. The thermal bimetallic sheet 8 is arranged vertically on the ventilation panel 1, and is located above the ventilation panel 1 as a whole. One end of the thermal bimetallic sheet 8 is connected to the ventila...

Embodiment 2

[0020] Example 2, such as figure 1 , 2 , 4 and 5, in order to further reduce the stress of the bimetal strip 8, a bearing mechanism is arranged on both sides of the bottom surface of the ventilation plate 1, and the grid plate 4 is arranged on the bearing mechanism, and the described bearing mechanism includes a ventilation plate 1 vertical limit riser 2, a horizontal support device 3 is arranged on the limit riser 2, and the grid plate 4 is placed on the horizontal support device 3; the horizontal support device 3 is a rolling bearing and a connecting shaft, and the rolling bearing is installed On the connecting shaft, the connecting shaft is connected with the limit riser 2, and the number of the horizontal supporting devices 3 is 4-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com