A multifunctional transfer device for internal threaded copper pipes

A transfer device, internal thread technology, applied in metal processing equipment, workshop equipment, metal processing machinery parts, etc., to save labor, improve labor efficiency, and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

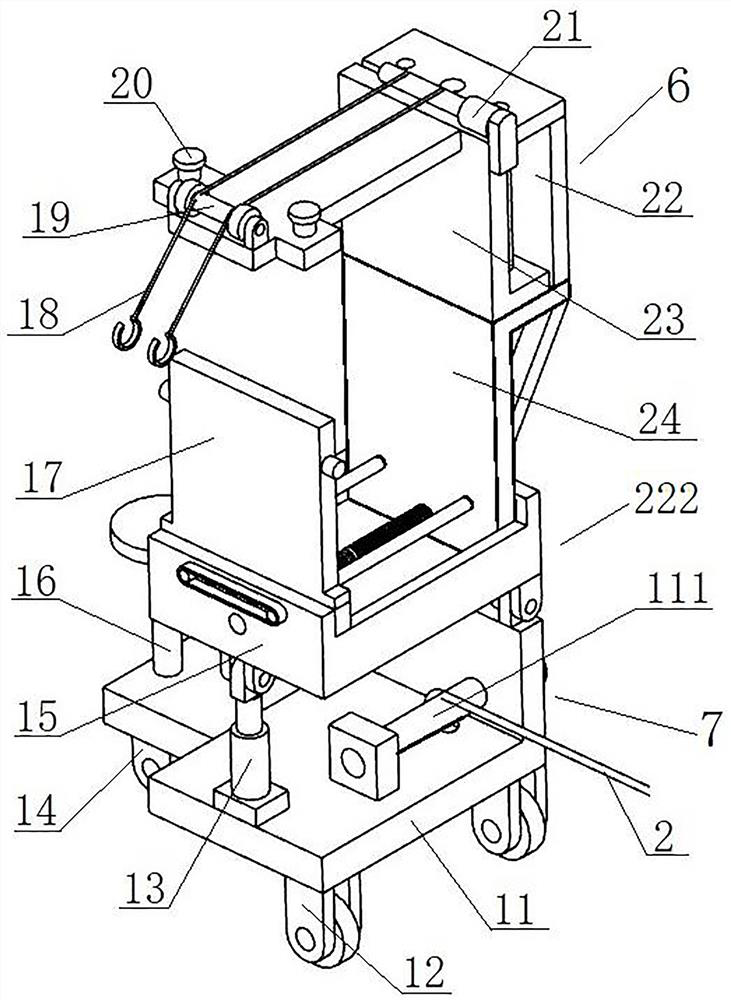

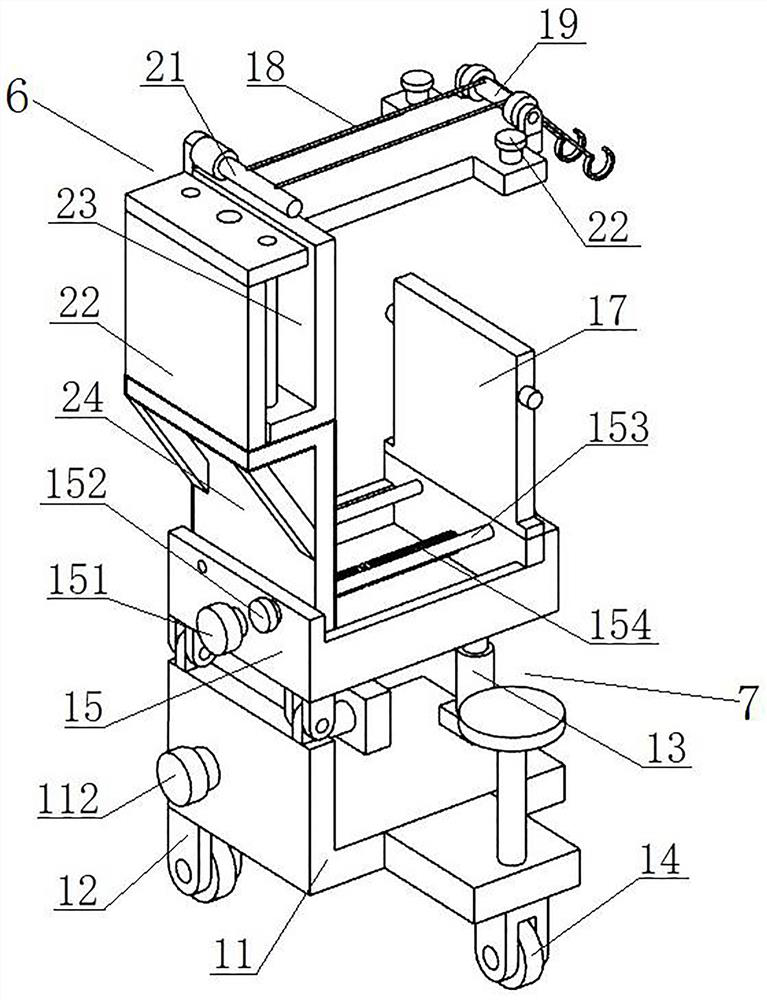

[0035] In order to more clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

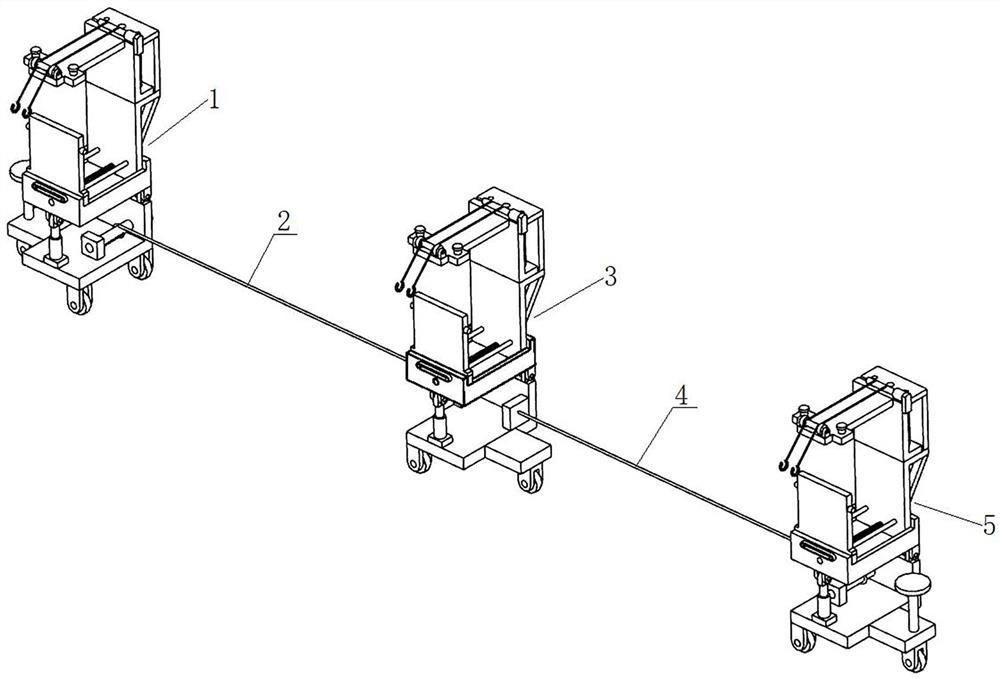

[0036] see figure 1 , a multifunctional transfer device for internal threaded copper pipes, comprising a transfer vehicle 1 1, a transfer vehicle 2 3 and a transfer vehicle 3 5 arranged in sequence from left to right, and the transfer vehicle 1 passes through the first pull rope 2 and the transfer vehicle. The second car 3 is connected, the transfer car two 3 is connected with the transfer car three 5 through the second pull rope 4, and the transfer car one 1 and the transfer car three 5 have the same structure;

[0037] Transfer vehicle one 1 and transfer vehicle three 5 both include moving system one 7 and support system one 6, transfer vehicle two 3 includes moving system two 9 and support system two 8, and support system one 6 and support system two 8 have the same structure;

[0038] The support system one 6 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com