Outer layer anti-rust treatment device for automobile part machining

A technology for anti-rust treatment and auto parts, applied in metal processing equipment, grinding/polishing safety devices, manufacturing tools, etc., can solve problems such as reducing work efficiency, reducing the service life of parts, and potential safety hazards, so as to avoid waste of oil , improve the service life, improve the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] as attached figure 1 to attach Figure 16 Shown:

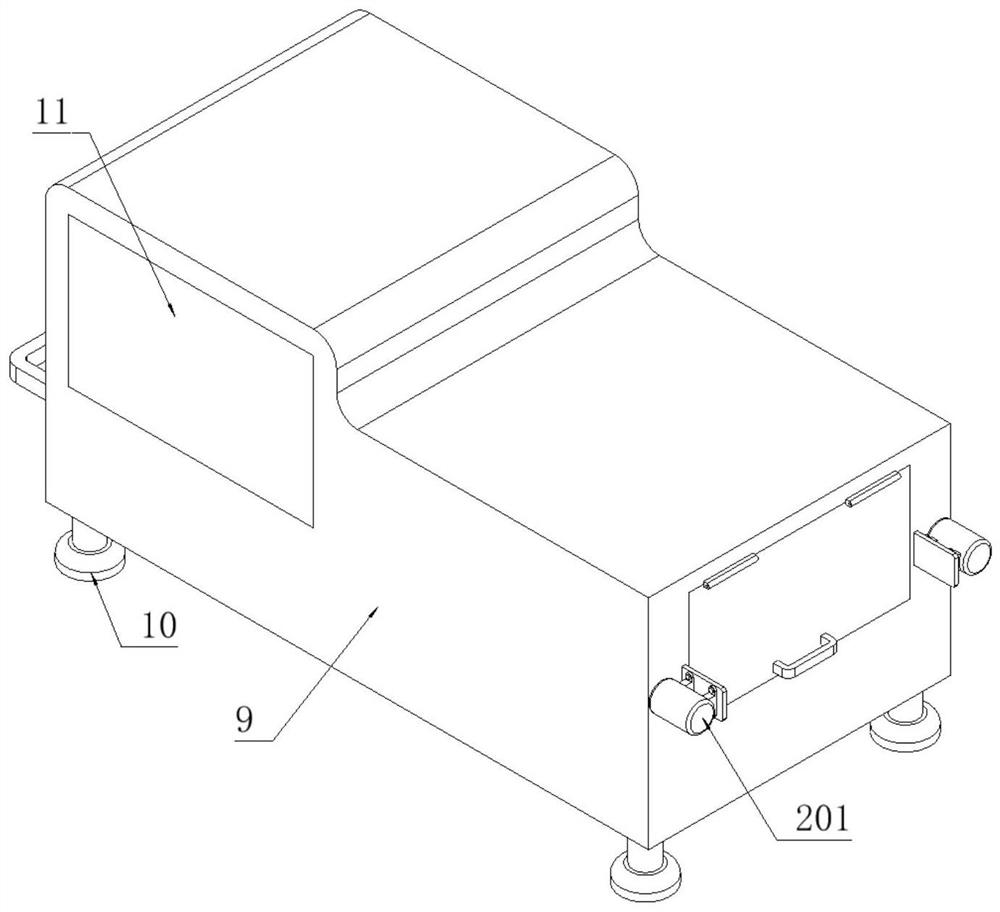

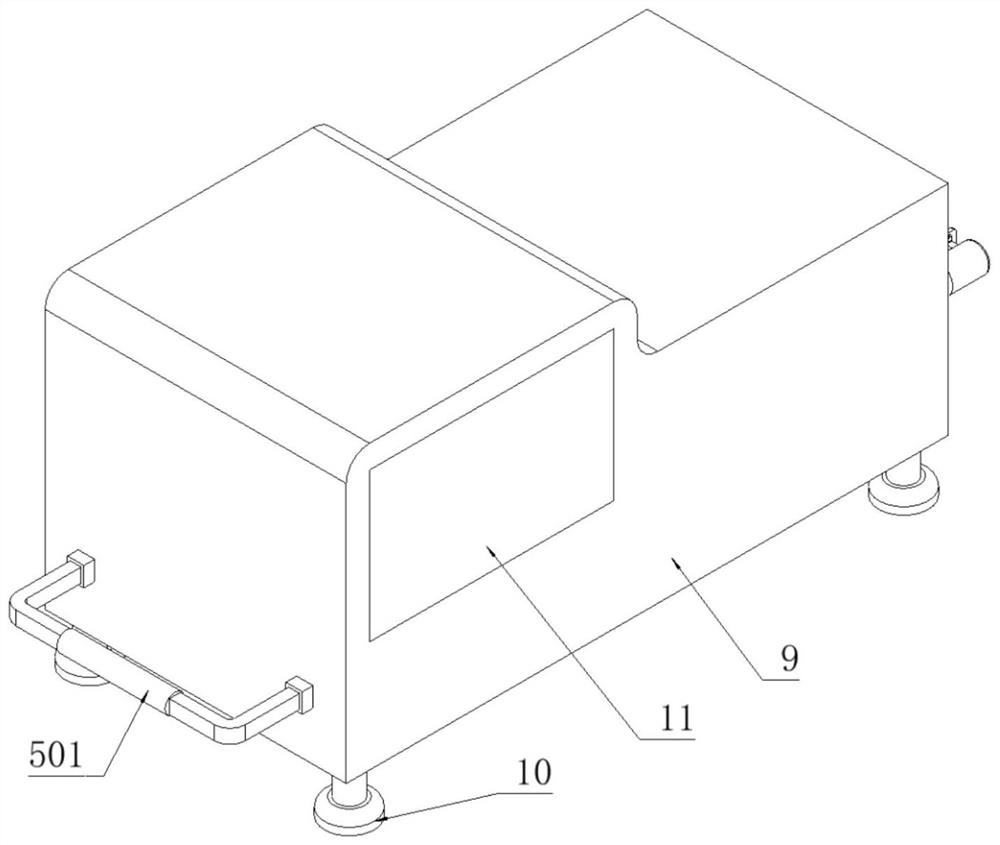

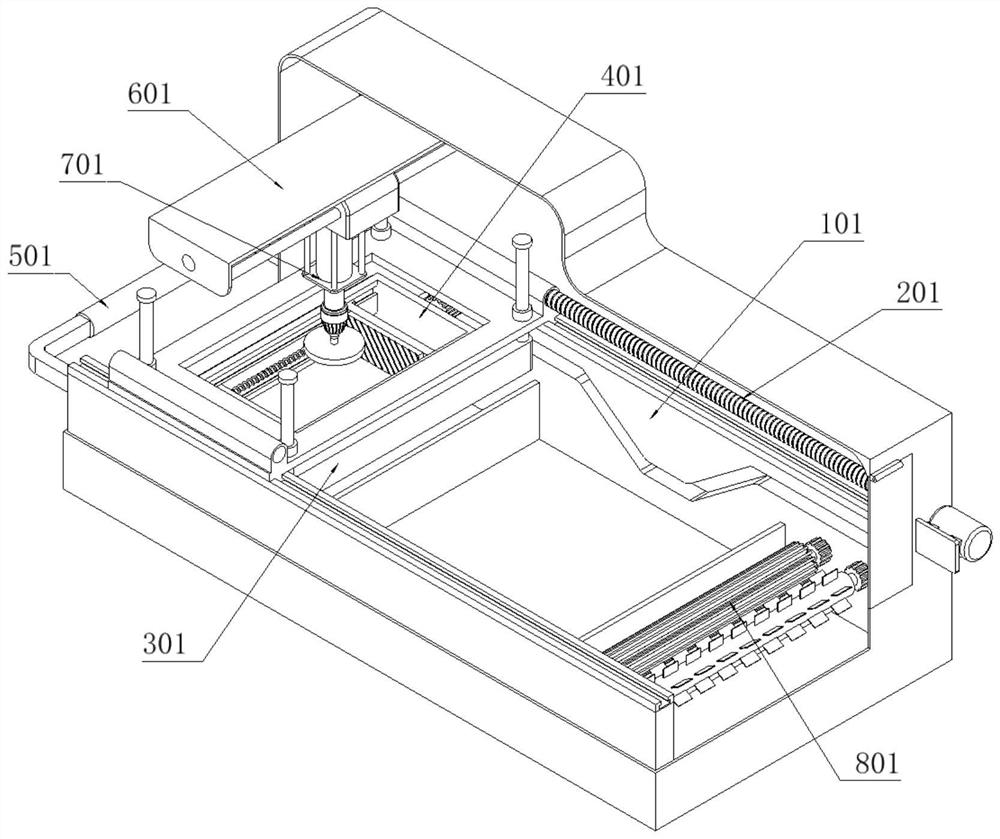

[0088] The invention provides an outer layer antirust treatment device for auto parts processing, which includes an operating device 1; a protective box 9 is installed on the outer side of the operating device 1, and an observation glass 11 is embedded on the protective box 9; the bottom of the protective box 9 The four corners are respectively fixedly connected with installation feet 10; the right side of the protective box 9 is provided with a feed door; the running device 1 is slidably connected with a driving device 2, and the driving device 2 is slidably connected with a floating support part 3; the floating support part 3 The upper rotation is connected with a positioning and turning device 4; the protective box 9 is slidably connected with a turning drive part 5; the cleaning acceleration part 8 is installed inside the protective box 9; Top side; the bottom of the grinding support part 6 is fixedly connected wi...

Embodiment 2

[0092] as attached Figure 11 to attach Figure 14As shown, the positioning overturning device 4 includes: an installation frame 401, which is rotatably connected to the floating bracket 301; two spherical grooves are provided on the side of the installation frame 401; an overturning gear 402, two overturning gears 402 are provided, and two Turning gear 402 is respectively fixedly connected to the both sides of installation frame 401; Positioning turning device 4 also comprises: positioning pusher plate 403, and positioning pusher plate 403 both sides slides and is connected in installation frame 401 inside; Extension spring 404, extension spring 404 is provided with two One, and two tension springs 404 are respectively fixedly connected between the positioning push plate 403 and the installation frame 401; the turning drive part 5 includes: a push rod 501, the push rod 501 is a "U" shape structure, and the push rod 501 is slidably connected to the On the protective box 9; th...

Embodiment 3

[0094] as attached Figure 16 As shown, the cleaning acceleration part 8 includes: a cleaning roller 801, which is rotatably connected to the inside of the protective box 9; a ventilation roller 802, which is rotatably connected to the inside of the protective box 9; a linkage gear 803, and the linkage gear 803 is provided with Two, and two interlocking gears 803 are respectively fixedly connected on the roller shafts of the cleaning roller 801 and the ventilating roller 802, and the set cleaning roller 801 and the ventilating roller 802 are respectively driven by the two interlocking gears 803 provided in the driving device 2. When the accessory moves to the right, the cleaning rack 304 on the floating support part 3 can engage with the two linkage gears 803, and the cleaning roller 801 and the ventilation roller 802 are driven to carry out the cleaning and ventilation roller 802 respectively during the reciprocating driving process of the two electric screw rods 201. Cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com