Hydraulic system of hydraulic aerial cage

A technology for aerial work vehicles and hydraulic systems, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, lifting devices, etc., and can solve the problems that hydraulic devices do not have cooling and filtering operations, shortened service life, etc., to avoid Uneven water temperature, improved cleanliness, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

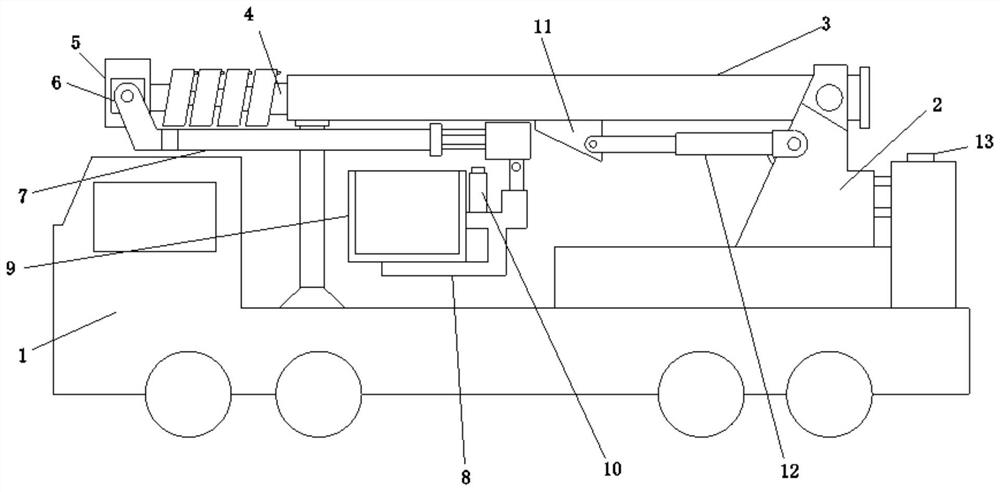

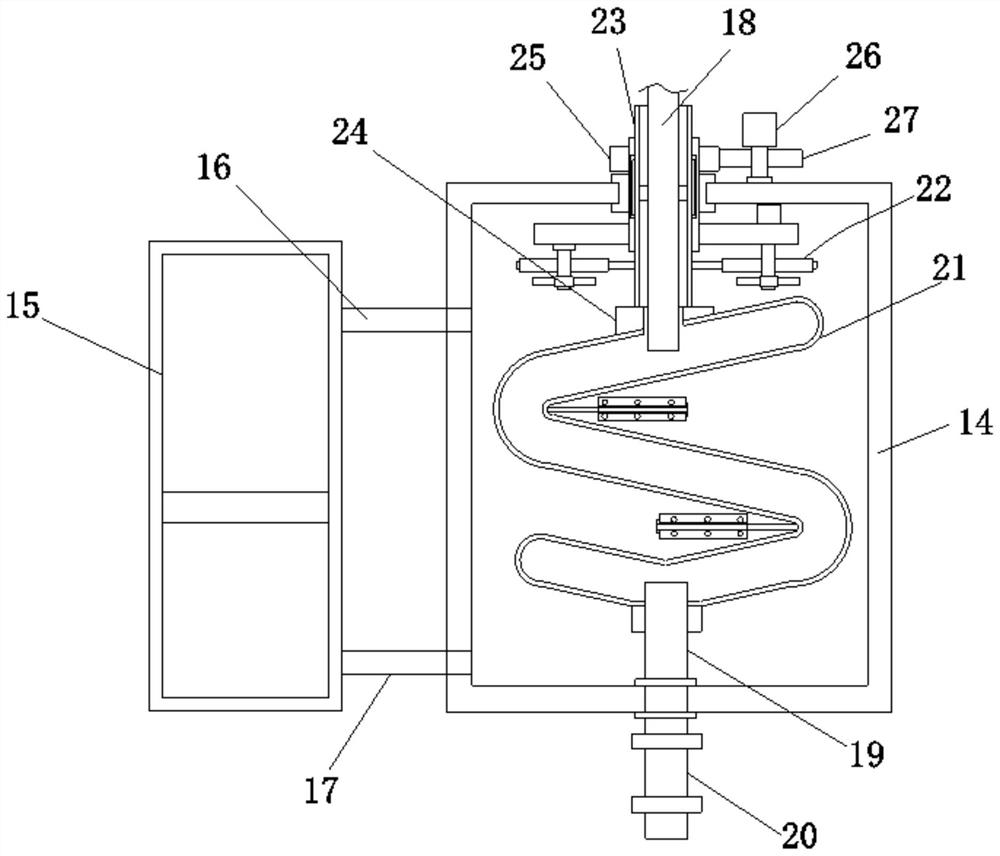

[0031] Embodiment one, by Figure 1 to Figure 6 Given, the present invention includes a work vehicle body 1, a support frame 2 is provided on the top of the work vehicle body 1, a main hydraulic cylinder 3 is movably connected to the top of the support frame 2, and a telescopic rod 4 is connected to the output shaft of the main hydraulic cylinder 3. One end of the rod 4 is connected with a joint 5, and one side of the joint 5 is movably connected with a connecting bracket 6, and one end of the connecting bracket 6 is provided with an insulating oil hydraulic rod 7, and one end of the insulating oil hydraulic rod 7 is connected with a mounting frame 8, and the mounting frame 8 Hanging basket 9 is installed on it, through the design of hanging basket 9, it is convenient to bring convenience to the work of the staff, and the top of the installation frame 8 and the work vehicle body 1 are provided with a fuel tank 10, and the top of the fuel tank 10 is provided with a filtering coo...

Embodiment 2

[0033] Embodiment two, on the basis of embodiment one, by figure 2 Given, the outer wall of the cooling pipe 21 is provided with a stirring shaft, and the outside of the stirring shaft is provided with a stirring blade, so as to realize the stirring of the cooling water, avoid the uneven temperature of the cooling water, and thereby accelerate the cooling rate of the oil.

Embodiment 3

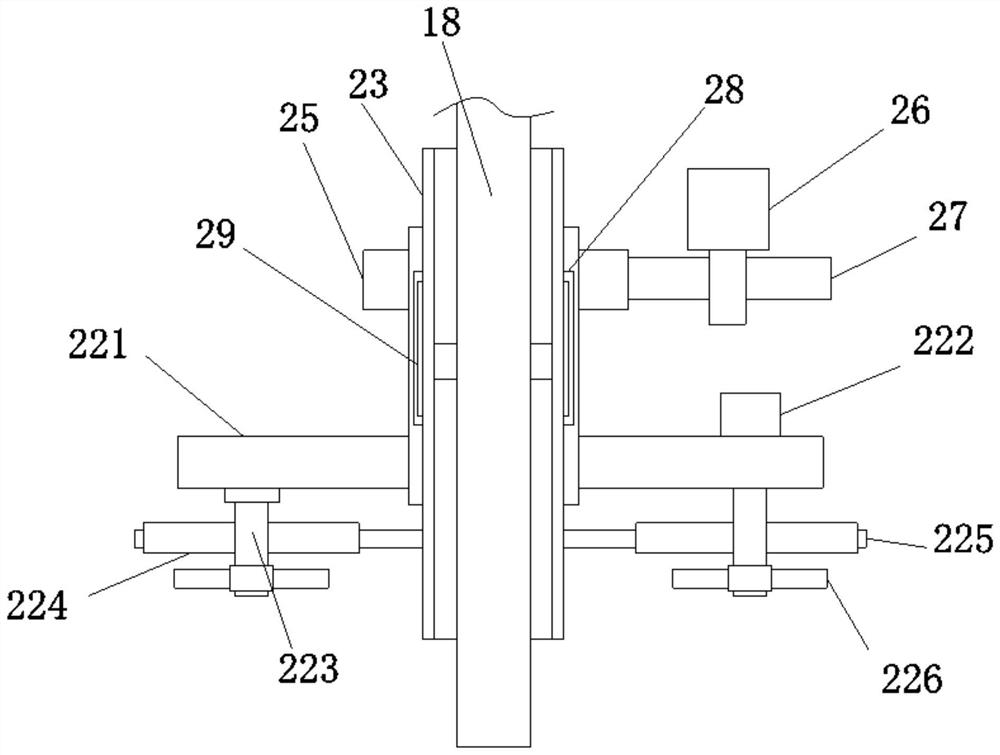

[0034] Embodiment three, on the basis of embodiment one, by figure 2 and image 3 Given, the sleeve 23 is symmetrically provided with a sliding plate 29 , and the inner wall of the collar is provided with a slide groove 28 slidably connected with the sliding plate 29 , so as to realize the protection of the sleeve 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com