Production method of gradient color spinning fabric

A production method and gradient color technology, which is applied in the processing of textile material equipment configuration, spray/jet textile material processing, textile and papermaking, etc., can solve the problems of complex wiring, heavy workload, unnatural transition, etc., and achieve a gradient effect Good, increase dyeing uniformity, moderate and uniform adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A production method of gradient color spun fabric, comprising the following production steps:

[0025] S1. Use an electrostatic generator to conduct electrostatic treatment on the surface of the fiber filaments, configure color pastes of different pigments according to the gradient color and place them in sequence, immerse the electrostatically treated fiber filaments in the color paste at a temperature of 60°C for 15 minutes, and dye During the continuous electrostatic treatment, the fiber scales on the surface of the fiber filaments are opened to fully absorb the color paste;

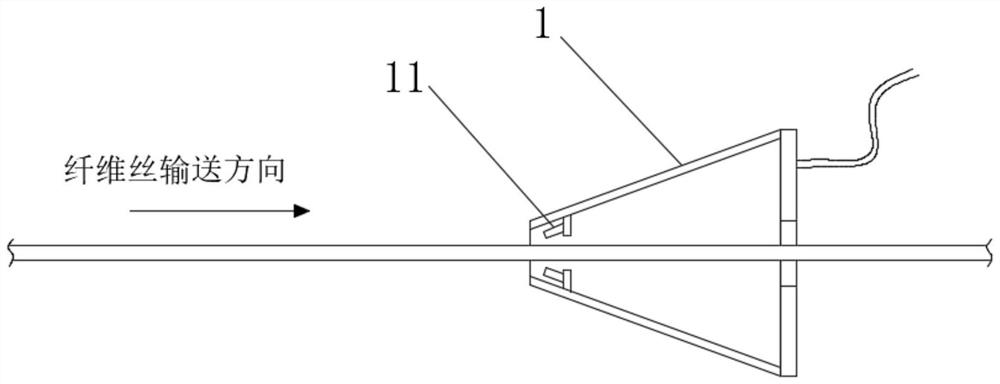

[0026] S2. Take out the fiber filaments and transport them. During the transportation process, the static electricity removal equipment is used to eliminate the static electricity of the fiber filaments, and then use water vapor to spray on the surface of the fiber filaments obliquely, so that the color paste on the surface is evenly distributed and the joints of different color pastes are fused...

Embodiment 2

[0030] A production method of gradient color spun fabric, comprising the following production steps:

[0031] S1. Use an electrostatic generator to conduct electrostatic treatment on the surface of the fiber filaments, configure color pastes of different pigments according to the gradient color and place them in sequence, immerse the electrostatically treated fiber filaments in the color paste at a temperature of 70°C for 10 minutes, and dye During the continuous electrostatic treatment, the fiber scales on the surface of the fiber filaments are opened to fully absorb the color paste;

[0032] S2. Take out the fiber filaments and transport them. During the transportation process, the static electricity removal equipment is used to eliminate the static electricity of the fiber filaments, and then use ethanol steam to spray obliquely on the surface of the fiber filaments, so that the color paste on the surface is evenly distributed and the joints of different color pastes are fus...

Embodiment 3

[0036] A production method of gradient color spun fabric, comprising the following production steps:

[0037] S1. Use an electrostatic generator to conduct electrostatic treatment on the surface of the fiber filaments, configure color pastes of different pigments according to the gradient color and place them in sequence, immerse the electrostatically treated fiber filaments in the color paste at a temperature of 60°C for 15 minutes, and dye During the continuous electrostatic treatment, the fiber scales on the surface of the fiber filaments are opened to fully absorb the color paste;

[0038] S2. Take out the fiber filaments and transport them. During the transportation process, the static electricity removal equipment is used to remove static electricity from the fiber filaments, and then the steam of the pigment penetrant is sprayed obliquely on the surface of the fiber filaments, so that the color paste on the surface is evenly distributed and the joints of different color ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com